Deep phosphorus removal method in acidic vanadium extraction solution

A solution and acidic technology, which is applied in the field of deep phosphorus removal in acidic vanadium extraction solution, can solve the adverse effects of polyacid radicals and other problems, achieve the effects of reduced loss of vanadium, poor stability, and improved metal recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

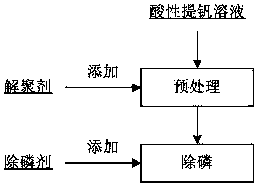

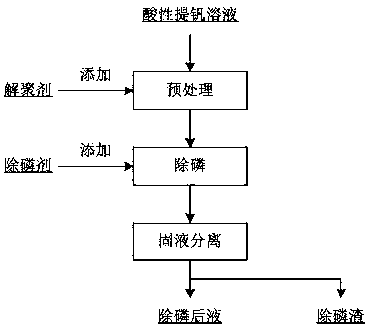

Method used

Image

Examples

Embodiment 1

[0039] The experimental raw material in this example, that is, the acidic vanadium extraction solution is the leaching solution obtained from vanadium slag through calcification roasting-acid leaching, containing 21g / L of vanadium and 1.4g / L of phosphorus, and the pH value of the solution is 2.6. Has a high recycling value.

[0040] A method for deep phosphorus removal in an acidic vanadium extraction solution, comprising the following steps:

[0041] S1: Add a depolymerizing agent to the solution, the depolymerizing agent is methylamine, the addition amount is 6mg / L, and stir evenly;

[0042] S2: Heat the solution of S1 after adding the depolymerization agent to 48°C, add a phosphorus removal agent to the solution, the phosphorus removal agent is aluminum sulfate, the addition amount is 0.8 times the phosphorus concentration, and the reaction time is 60 minutes.

[0043] After the reaction, it was measured that the phosphorus removal rate was 99.3%, the vanadium loss rate wa...

Embodiment 2

[0045] The experimental raw material in this example is the leaching solution obtained from vanadium slag through calcification roasting-acid leaching, containing 15g / L of vanadium and 0.8g / L of phosphorus, and the pH value of the solution is 3.2. Has a high recycling value.

[0046] A method for deep phosphorus removal in an acidic vanadium extraction solution, comprising the following steps:

[0047] S1: Add a depolymerizing agent to the solution, the depolymerizing agent is a compound of ethylamine and ethylenediamine, the mass ratio of ethylamine and ethylenediamine is 1:1, the addition amount is 5mg / L, and stir evenly;

[0048] S2: Heat the solution of S1 after adding the depolymerization agent to 50°C, add a phosphorus removal agent to the solution, the phosphorus removal agent is iron sulfate, the addition amount is 1.0 times the phosphorus concentration, and the reaction time is 80 minutes.

[0049] After the reaction, it was measured that the phosphorus removal rate ...

Embodiment 6

[0053] In Example 6, the depolymerizing agent is a compound of methylamine and ethylamine, and the mass ratio of methylamine and ethylamine is 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com