Catalyst for decomposition of ozone in gases and preparation method of catalyst

An ozonolysis and catalyst technology, applied in catalyst activation/preparation, separation methods, chemical instruments and methods, etc., can solve the problems of poor binding force between active ingredients and carriers, dust shedding, complex preparation process, etc., to avoid risk factors and The effect of unfavorable conditions, low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

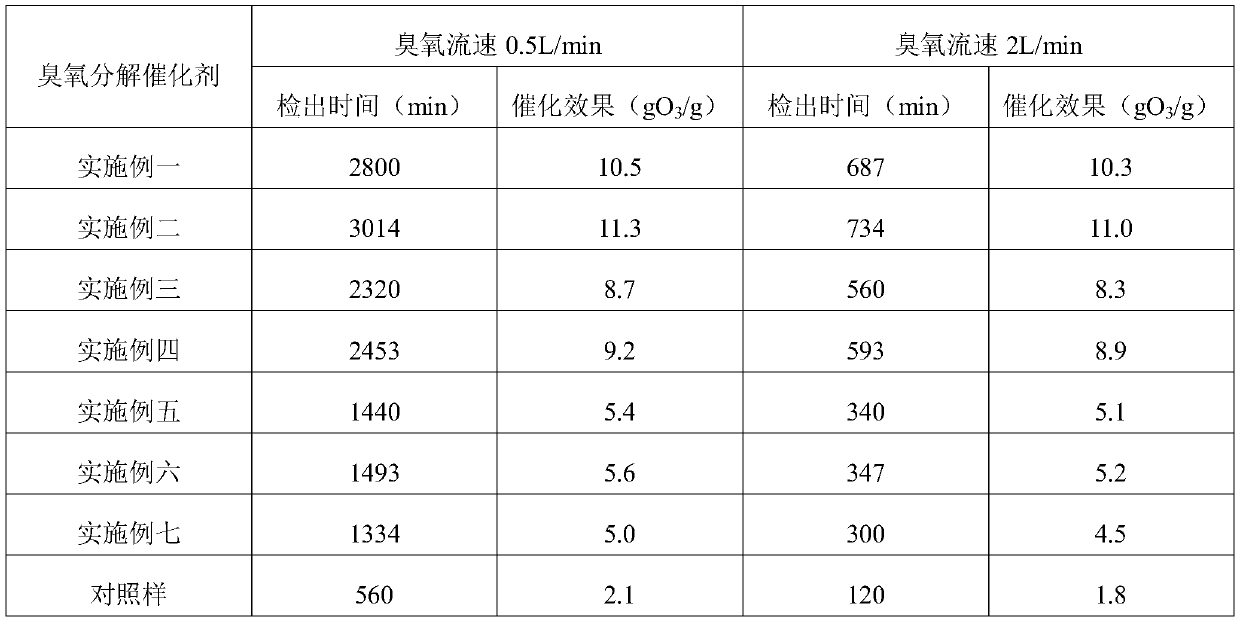

Examples

preparation example Construction

[0021] A kind of preparation method of catalyst for ozone decomposition in gas of the present invention comprises the following steps:

[0022] S1: Preparation of fibrous porous conductive carbon black

[0023] 1) Take the following raw materials in parts by weight: 100 parts of conductive carbon black, 5-10 parts of polytetrafluoroethylene emulsion, 10-15 parts of pore-forming agent and 40-60 parts of distilled water;

[0024] 2) Add polytetrafluoroethylene emulsion, pore-forming agent and distilled water to the conductive carbon black, mix, adjust into a paste, stir, and filter to obtain a slurry;

[0025] 3) Roll the slurry repeatedly. When rolling, the temperature of the slurry is 40-60°C, and the rolling time is 1-2h. Extrude, shape, and solidify. The curing temperature is 300-350°C, and the curing time is 3- 5h, furnace cooling, to obtain fibrous porous conductive carbon black;

[0026] S2: Preparation of catalyst for ozonolysis

[0027] 4) Take the electrolyte, which i...

Embodiment 1

[0040] A kind of preparation method of catalyst for ozone decomposition in gas of the present invention comprises the following steps:

[0041] S1: Preparation of fibrous porous conductive carbon black

[0042] 1) Take the following raw materials in parts by weight: 100 parts of conductive carbon black, 5 parts of polytetrafluoroethylene emulsion, 10 parts of pore-forming agent and 40 parts of distilled water;

[0043] 2) Add polytetrafluoroethylene emulsion, pore-forming agent and distilled water to the conductive carbon black, mix, adjust into a paste, stir, and filter to obtain a slurry;

[0044] 3) Roll the slurry repeatedly. When rolling, the temperature of the slurry is 40°C, and the rolling time is 2 hours. Extrude, shape, and solidify. The solidification temperature is 300°C, and the solidification time is 3 hours. Cool in a furnace to obtain a fibrous shape Porous conductive carbon black;

[0045] S2: Preparation of catalyst for ozonolysis

[0046] 4) Take 1L of el...

Embodiment 2

[0050] A kind of preparation method of catalyst for ozone decomposition in gas of the present invention comprises the following steps:

[0051] S1: Preparation of fibrous porous conductive carbon black

[0052] 1) Take the following raw materials in parts by weight: 100 parts of conductive carbon black, 10 parts of polytetrafluoroethylene emulsion, 15 parts of pore-forming agent and 60 parts of distilled water;

[0053] 2) Add polytetrafluoroethylene emulsion, pore-forming agent and distilled water to the conductive carbon black, mix, adjust into a paste, stir, and filter to obtain a slurry;

[0054] 3) Roll the slurry repeatedly. When rolling, the temperature of the slurry is 60°C, and the rolling time is 1h. Extrude, shape, and solidify. The solidification temperature is 350°C, and the solidification time is 5h. Cool in a furnace to obtain a fibrous shape Porous conductive carbon black;

[0055] S2: Preparation of catalyst for ozonolysis

[0056] 4) Take 1L of electrolyte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com