A kind of superabsorbent resin, its preparation method and application

A technology of super absorbent resin and aqueous solution, applied in fire protection equipment and other directions, can solve the problems of increased adhesion effect, poor adhesion, and increased production cost of fire extinguishing agent, and achieves the effect of high fire extinguishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention provides a kind of preparation method of superabsorbent resin, comprises the following steps:

[0031] A) mixing an aqueous solution of an ethylenically unsaturated monomer with an initiator to obtain an aqueous solution; mixing a hydrocarbon dispersion medium with a surfactant to obtain an oily solution;

[0032] B) After mixing the aqueous solution and the oily solution, stir to obtain a super absorbent resin; the rotational speed of the stirring is 500-800 rpm.

[0033] The invention mixes the aqueous solution of the ethylenically unsaturated monomer and the initiator to obtain the aqueous solution.

[0034] In some embodiments of the present invention, the ethylenically unsaturated monomer includes one or more of acrylic acid, acrylate, methacrylic acid, methacrylate and acrylamide.

[0035] In some embodiments of the present invention, the mass concentration of the aqueous solution of the ethylenically unsaturated monomer is 30-100%.

[0036...

Embodiment 1

[0068] Step 1: Prepare an aqueous solution: add 100 g (1.11 mol) of acrylic acid aqueous solution with a mass concentration of 80% to a 300 mL beaker, then add 0.03 g (0.000111 mol) of potassium persulfate, and mix at 25° C.

[0069] Step 2: Prepare an oily solution: Add 600 mL of n-hexane and 1.2 g of polyoxyethylene alkyl ether phosphate into a round bottom flask, and raise the temperature to 70°C.

[0070] The above aqueous solution was added to the above oily solution, and stirred at 60°C and 600 rpm for 20 minutes to obtain a super absorbent resin.

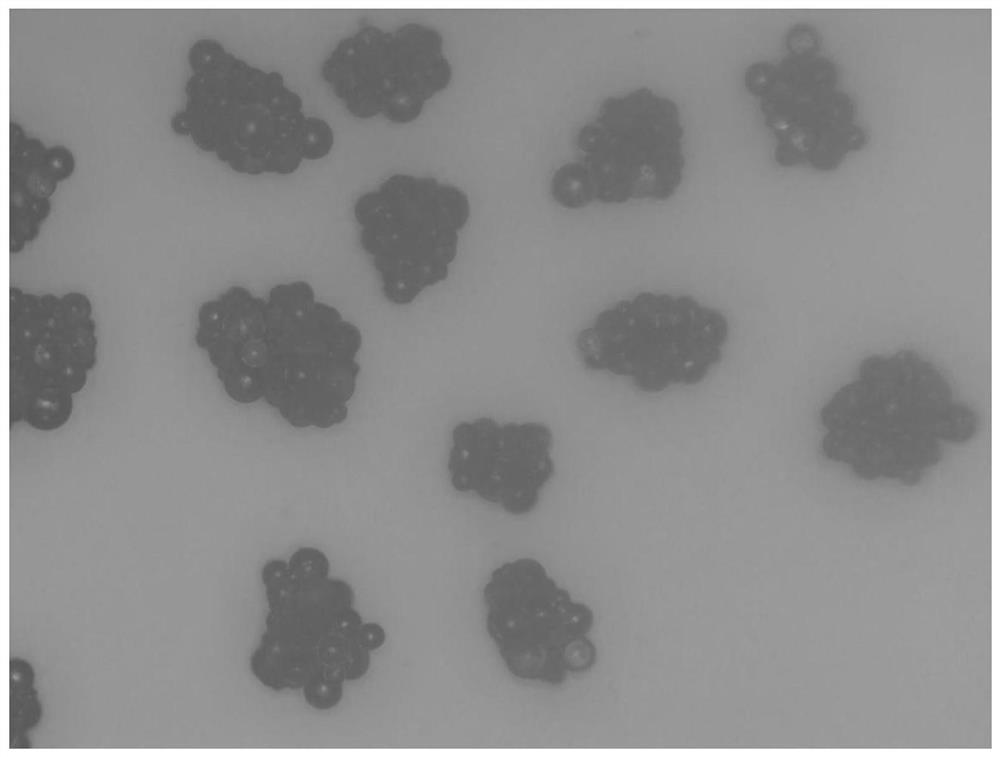

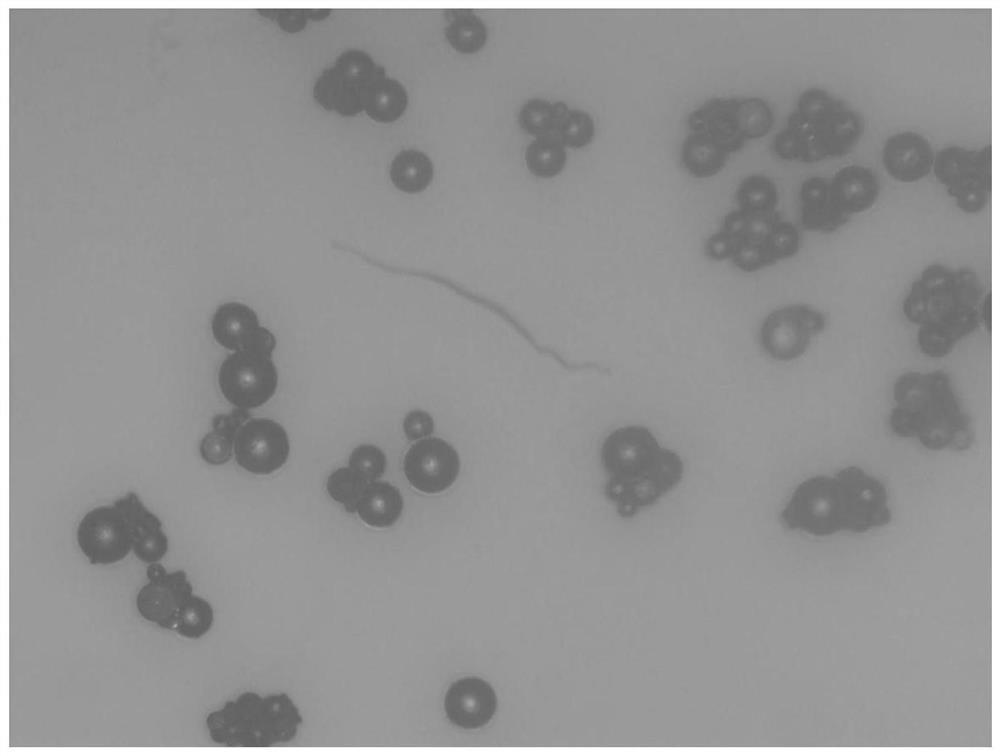

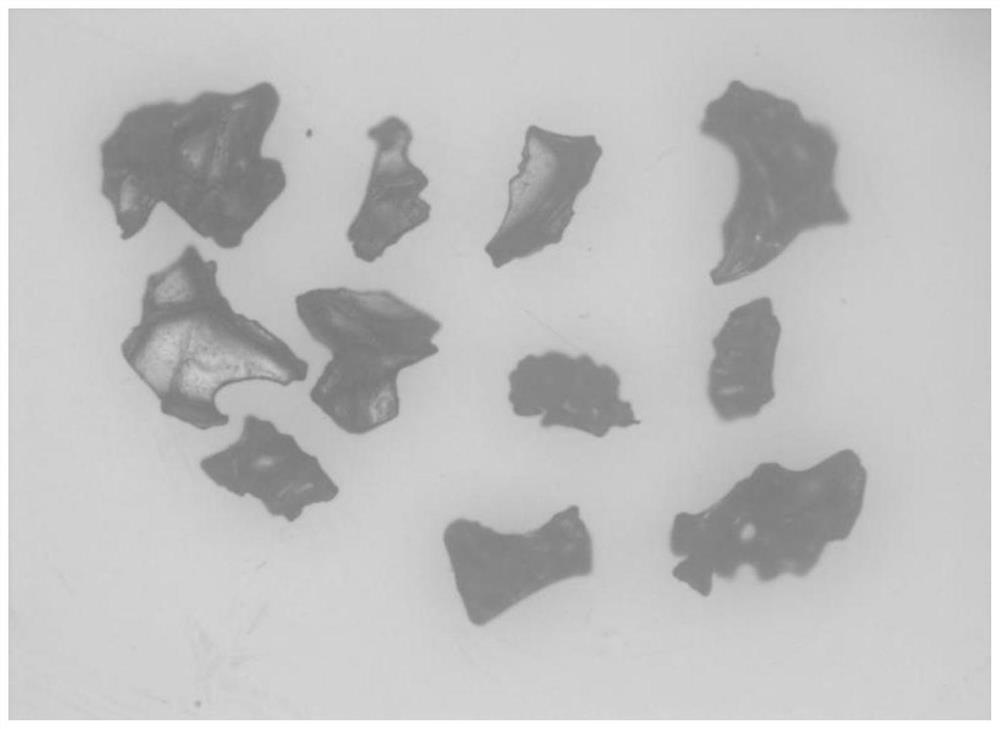

[0071] The superabsorbent resin that embodiment 1 obtains is carried out polarizing microscope analysis, and the result is as follows figure 1 shown. figure 1 It is a polarizing microscope picture of the superabsorbent resin prepared in Example 1 of the present invention. from figure 1 It can be seen that the superabsorbent resin particles are large particles with a rough surface obtained by aggregating a plurality of smal...

Embodiment 2

[0073] Step 1: Prepare an aqueous solution: add 95g (1.05mol) of acrylic acid aqueous solution with a mass concentration of 80% to a 300mL beaker, then add 0.09g (0.000333mol) of potassium persulfate, and mix at 30°C.

[0074] Step 2: Prepare an oily solution: Add 600 mL of n-heptane and 1.5 g of polyoxyethylene alkyl ether phosphate into a round bottom flask, and raise the temperature to 80°C.

[0075] The above aqueous solution was added to the above oily solution, stirred at 70° C. and 650 rpm for 30 min to obtain a super absorbent resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com