Coating composition

A technology of coating composition and derivatives, applied in the direction of ink, household utensils, applications, etc., can solve problems such as limited use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

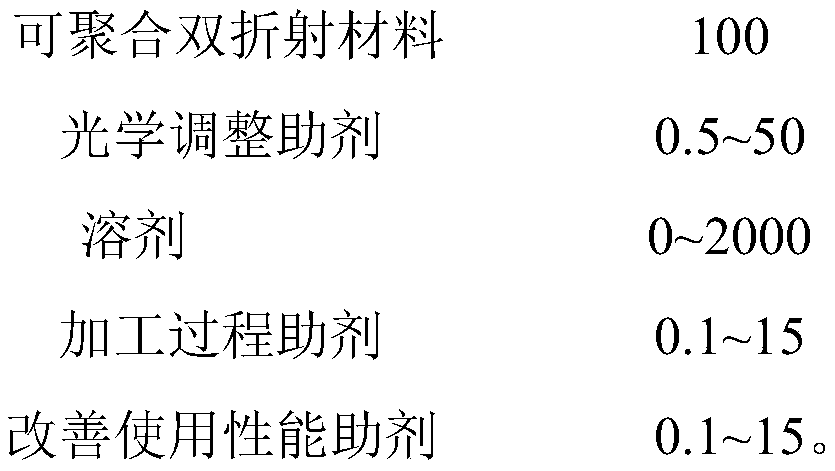

[0116] Take any one of the P2 series of polymerizable birefringent materials such as: P2-1-04: 100 parts, and then add 0.3 parts of methoxyphenol and any one of the optical adjustment additives, such as S811: 50 parts to combine the above-mentioned composition The material is heated to 20°C-80°C and stirred at 1000rpm until the material melts into a molten paste.

[0117] Then add photoinitiator TPO: 3 parts, ultraviolet absorber UV-531: 0.5 part, conductive agent BZ-33: 0.01 part, release agent 1 part to the composition, heat and stir together in the above molten paste uniform.

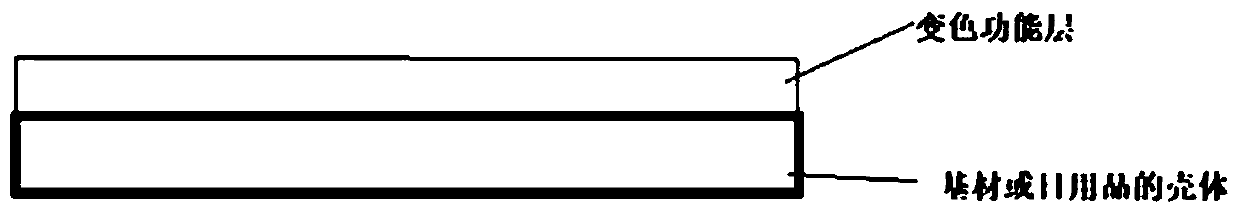

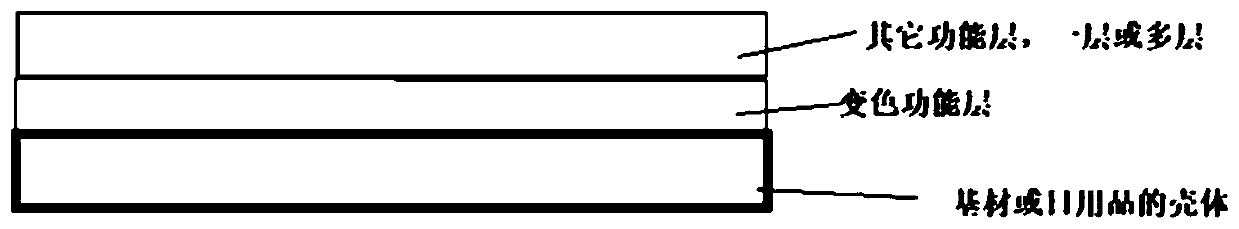

[0118] After the materials are evenly stirred, the above combination is processed onto paper, PET, books, refrigerators, communication tools, and TVs by hot stamping, silk screen printing, gravure printing, etc., and then irradiated by UV light. After post-curing, a color-changing functional layer that can reflect blue-violet light is obtained, which can play a decorative role in giving daily necess...

Embodiment 2

[0120]Take any one of the P2 series of polymerizable birefringent materials such as: P2-1-04: 100 parts, hindered amine inhibitor 701: 0.4 parts, optical adjustment additive RS-1: 4 parts, MIBK: 500 parts The above-mentioned materials of the composition are stirred at 2000 rpm at normal temperature to form a transparent solution.

[0121] Then add photoinitiator 819: 3 parts, ultraviolet absorber phenyl salicylate: 0.5 parts, leveling agent Tween-20: 5 parts, EA series EA-15 conductive agent of Santuo Chemical in the above solution 1 part, Dow Corning hand feeling agent DC-18: 0.1 part is added to the composition, heated and stirred together, and filtered to obtain a ready-to-use solution.

[0122] The above solution is processed by inkjet printing process on paper, PC, PU, PET and other substrates or on daily necessities refrigerators, TVs, millet bracelets, desktops, kitchen countertops, ceramic tiles, communication tool sheaths, and communication tools. On the shell of t...

Embodiment 3

[0124] Take any two of the P2 series of polymerizable birefringent materials, such as P2-1-10: 10 parts, P2-1-08: 90 parts, and then mix with hindered amine inhibitor 701: 0.4 parts, optical adjustment additive RS-2: 3 parts, mixed solvent 500 parts, photoinitiator 651: 4 parts, ultraviolet absorber UV-329: 3 parts, leveling agent Tween-80: 3 parts, natural propolis antibacterial agent 1 part, Dow Corning Hand feeling agent DC-21 and hand wax Lanco TF1778: 0.02 parts are added to the composition, and stirred together at room temperature at a stirring speed of 500-3000rpm to form a transparent solution.

[0125] After the above solution is filtered, it is processed onto PU, PET and other substrates or furniture, refrigerators, wireless communication phone casings, and TV casings by dip-dyeing technology to form a whole-surface pattern. After drying and UV irradiation, a color-changing cured functional layer is obtained. The functional layer has a reflection peak in the visible ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com