Method for preparing basic lead sulfate and basic lead sulfate electrode from lead sulfate and lead oxide

A lead sulfate and lead oxide technology, applied in lead sulfate, lead-acid battery electrodes, battery electrodes, etc., can solve problems such as difficulties and shattering, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

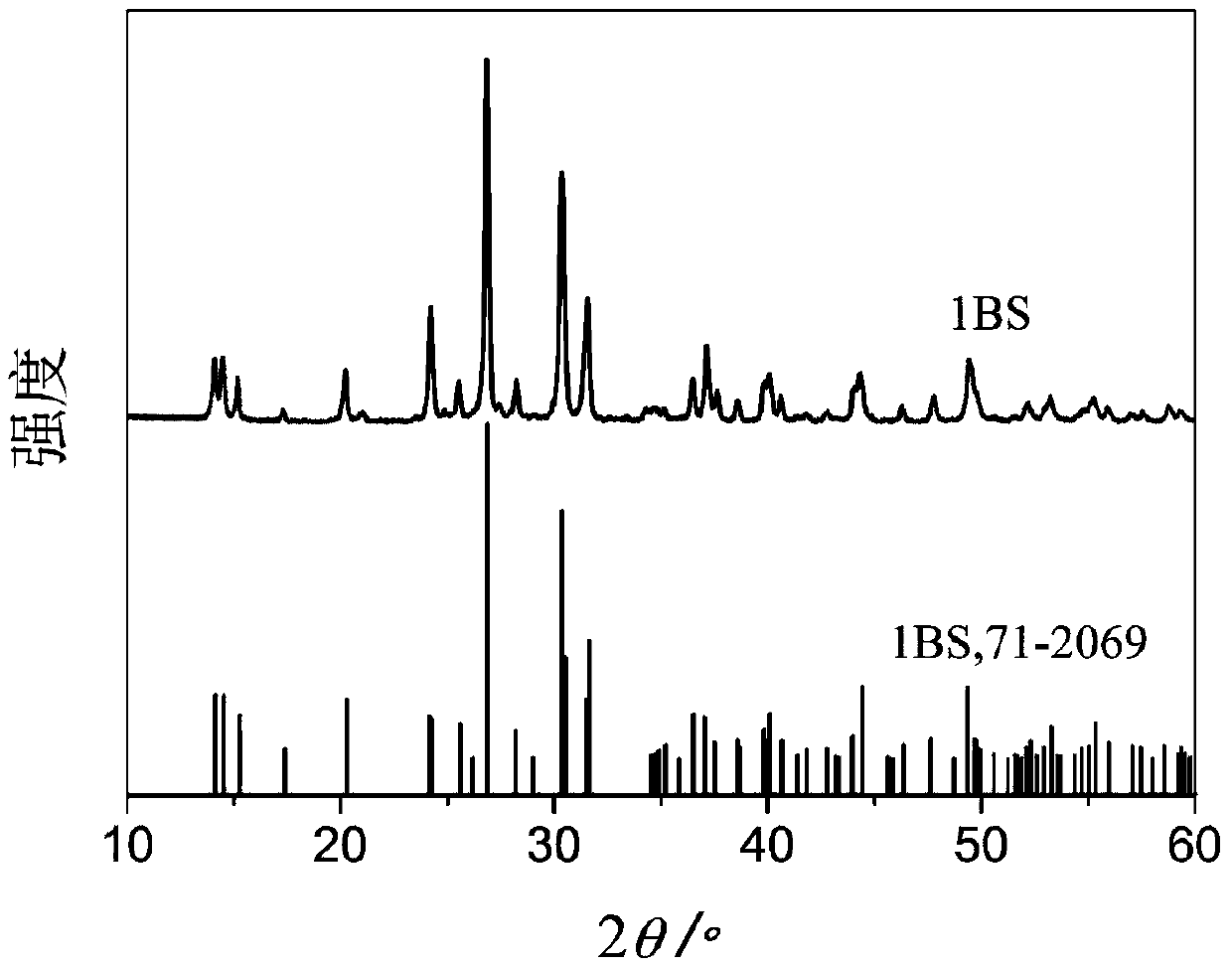

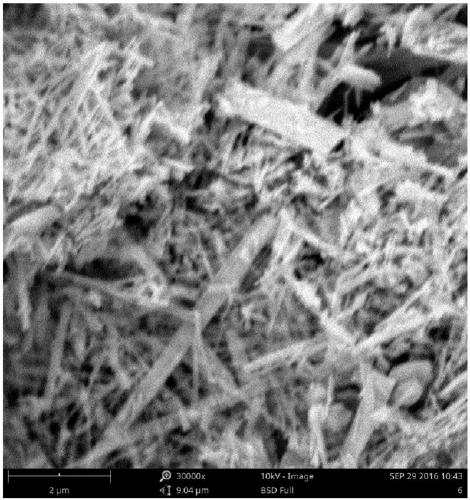

[0059] The synthesis of embodiment 1 basic lead sulfate

[0060] Disperse PbO and lead sulfate in water according to the molar ratio shown in Table 1, and stir and react at the specified temperature for 1 to 6 hours to obtain the corresponding basic lead sulfate:

[0061] The synthetic reaction conditions of table 1 basic lead sulfate

[0062]

Embodiment 2

[0063] Embodiment 2 manufactures lead sulfate with the lead compound of waste lead-acid battery

[0064] (1) crushing waste lead-acid batteries, and then sorting to obtain lead compounds, lead alloys, plastics and sulfuric acid;

[0065] (2) the lead compound is desulfurized with ammonium carbonate, then reduced with a reducing agent, and the product obtained is reacted with substances such as nitric acid and acetic acid to obtain a soluble lead salt solution;

[0066] (3) soluble lead salt solution reacts with the sulfuric acid that step 1 obtains to obtain lead sulfate.

[0067] Described reductant (comprising its oxidation product) can be any not with Pb 2+ It forms substances that are insoluble in acid substances such as nitric acid and acetic acid. For example, methanol, nitrite, etc.

Embodiment 3

[0068] Embodiment 3 manufactures PbO with lead sulfate

[0069] (1) lead sulfate and ammonium carbonate are reacted in aqueous solution, obtain lead carbonate and ammonium sulfate solution;

[0070] (2) Heating lead carbonate at 350-650°C under air isolation to obtain PbO;

[0071] (3) Evaporate and concentrate the ammonium sulfate solution, and then crystallize to obtain ammonium sulfate that can be used as a chemical fertilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com