Method for continuously preparing graphene powder in bulk

A graphene and powder technology, which is applied in the field of continuous large-scale preparation of powder graphene, can solve problems such as pollution, high oxygen content, and complicated post-processing, and achieve the effect of large application prospects, low oxygen content, and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The powder graphene continuous heavy-duty preparation method provided by the present invention is realized by a microwave plasma chemical vapor deposition system, comprising the following steps:

[0041] S1, feeding an inert gas into the microwave plasma chemical vapor deposition system to generate plasma;

[0042] S2, introducing a carbon source into the microwave plasma chemical vapor deposition system for vapor phase growth of powdered graphene;

[0043] S3, stop feeding the carbon source, and feed the etchant to etch the residual graphene in the microwave plasma chemical vapor deposition system; and

[0044] S4, repeat steps S1-S3, to realize the continuous large-scale preparation of powder graphene.

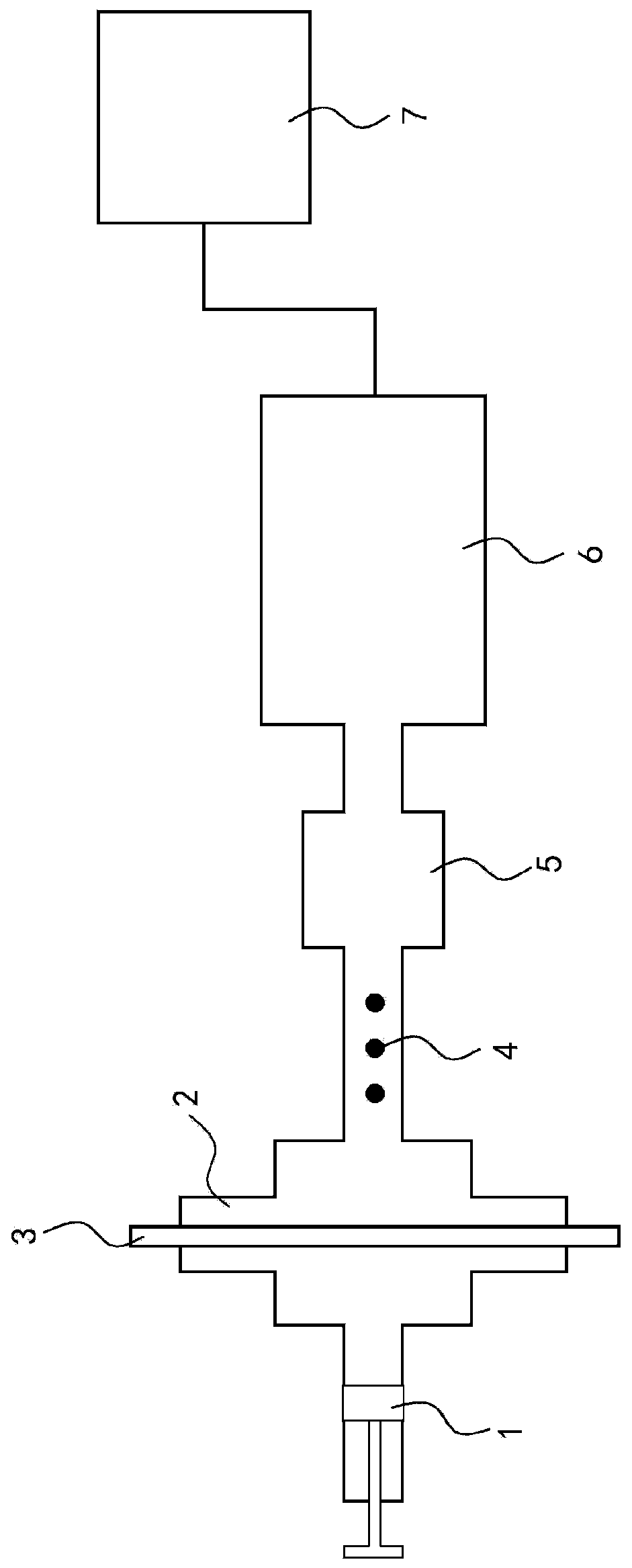

[0045] figure 1 It is a structural schematic diagram of the microwave plasma chemical vapor deposition system adopted in the present invention, as figure 1 As shown, the microwave plasma chemical vapor deposition system includes a short circuit 1 , a microwave reac...

Embodiment 1

[0062] use as figure 1 In the shown microwave plasma chemical vapor deposition system, 1200 sccm Ar is introduced to blow off the residual air in the system.

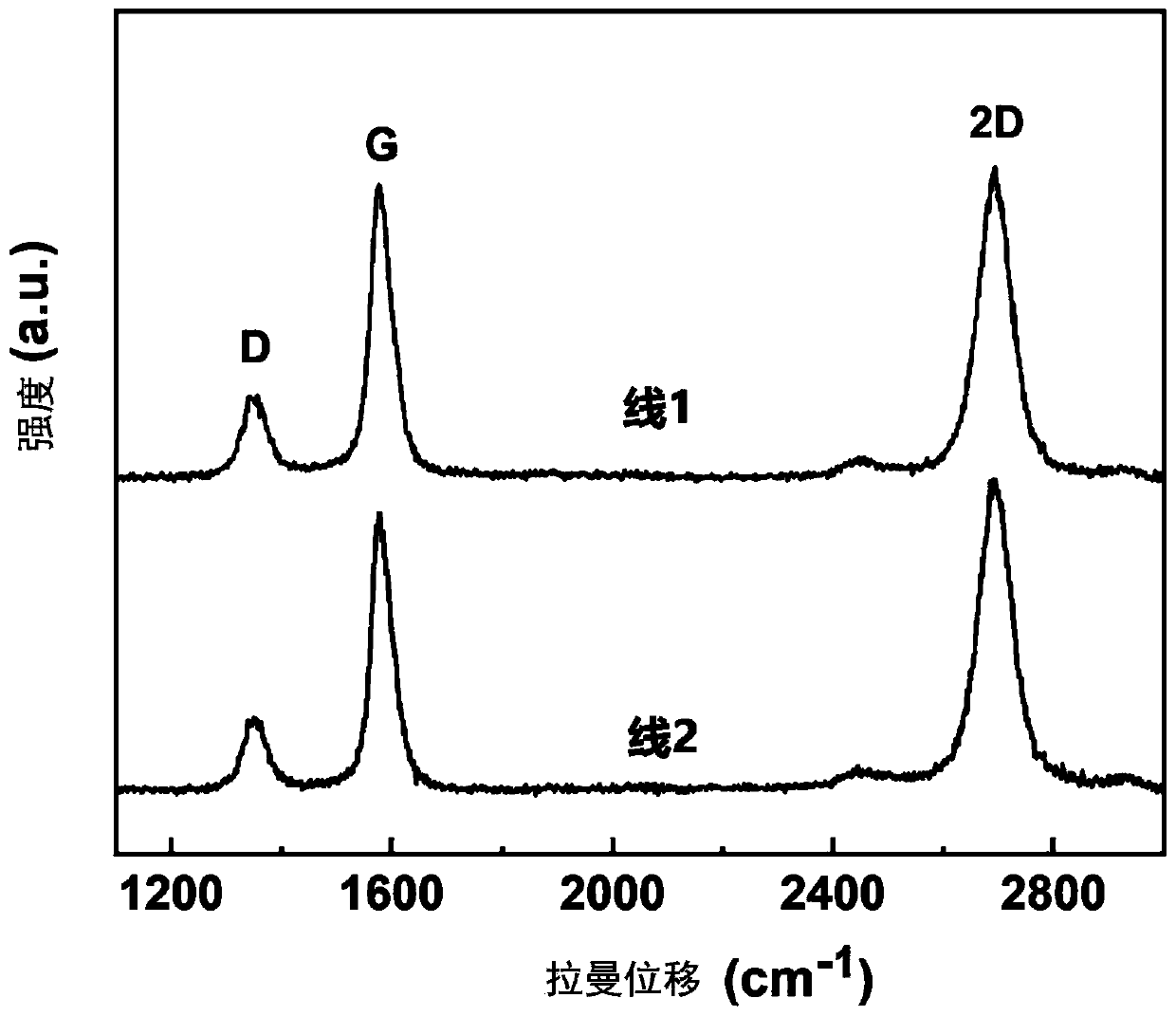

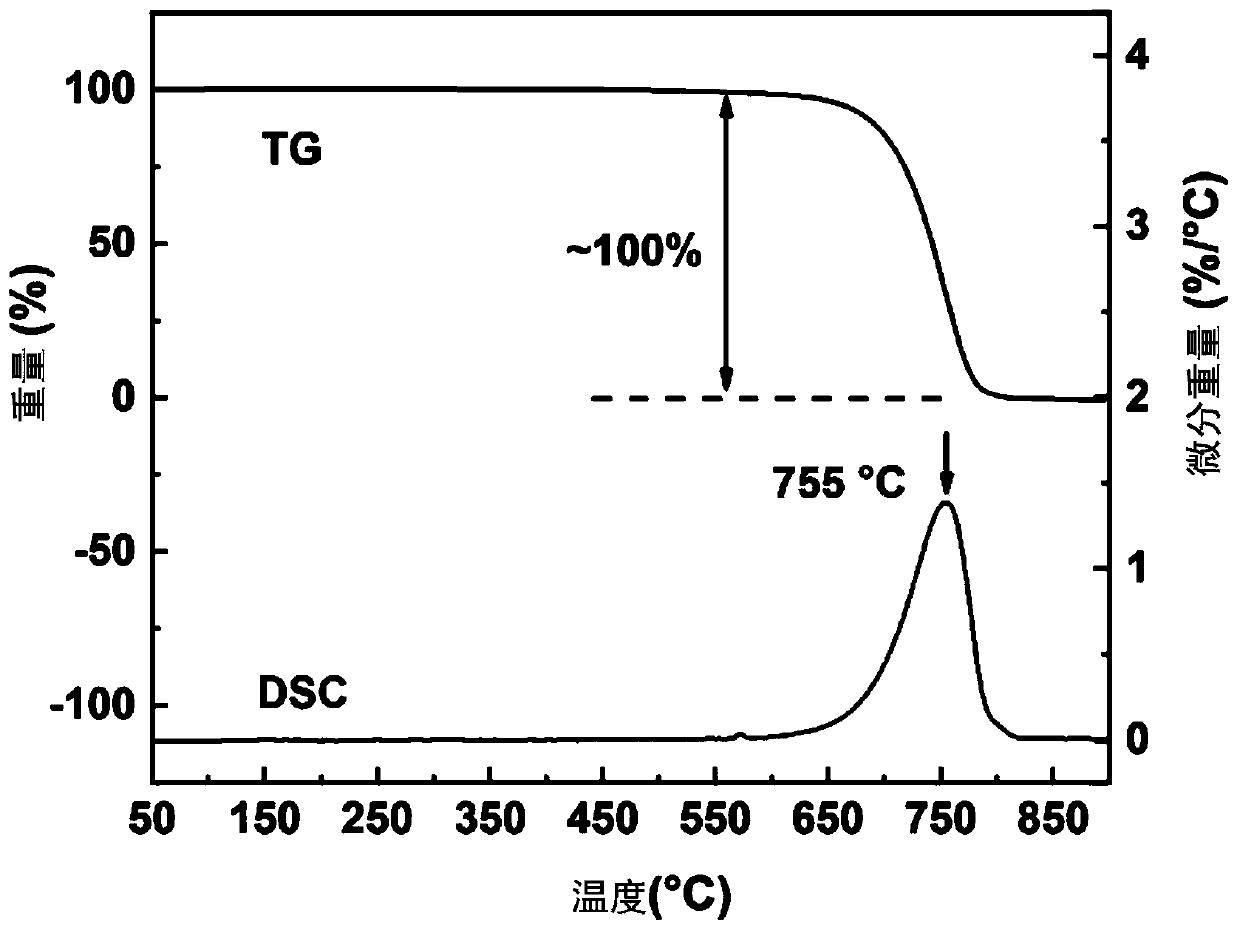

[0063] By adjusting the microwave power to 700W and initiating the system to generate Ar plasma, and then passing 3sccm CH 4 into the system. At this time, the system produces bright luminescence, and at the same time, black flocs can be seen continuously drifting away from the system at the end of the quartz tube, and the black flocs are collected.

[0064] After about 25 minutes of reaction, close the CH 4 Flowmeter, and it can be seen that there are many black substances remaining on the quartz tube wall in the microwave reaction chamber area. Under the power of 700W, 9.9sccm oxygen is introduced into the system at this time, and the black carbon substance can be seen to gradually decrease through the opening of the reaction chamber 2. After about 1 to 2 minutes, it can be seen that there is no obvious black subst...

Embodiment 2

[0073] use as figure 1 In the shown microwave plasma chemical vapor deposition system, 1200 sccm Ar is introduced to blow off the residual air in the system.

[0074] By adjusting the microwave power to 700W and initiating the system to generate Ar plasma, and then passing 3sccm CH 4 into the system. At this time, the system produces bright luminescence, and at the same time, black flocs can be seen continuously drifting away from the system at the end of the quartz tube, and the black flocs are collected.

[0075] After about 25 minutes of reaction, close the CH 4 Flowmeter, and it can be seen that there are many black substances remaining on the quartz tube wall in the microwave reaction chamber area. At this time, 9.9 sccm oxygen was introduced into the system, and after about 1 to 2 minutes, no obvious black substance remained on the quartz tube wall in the microwave reaction chamber area, indicating that the remaining graphene in this area was completely etched.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com