Early-strength polycarboxylate superplasticizer, and preparation method and application thereof

A technology of polycarboxylic acid and water reducing agent, applied in the field of concrete admixtures, can solve the problems of affecting the strength of concrete, complicated preparation process, etc., and achieve the effects of improving slump and plasticity, high strength, and improving early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

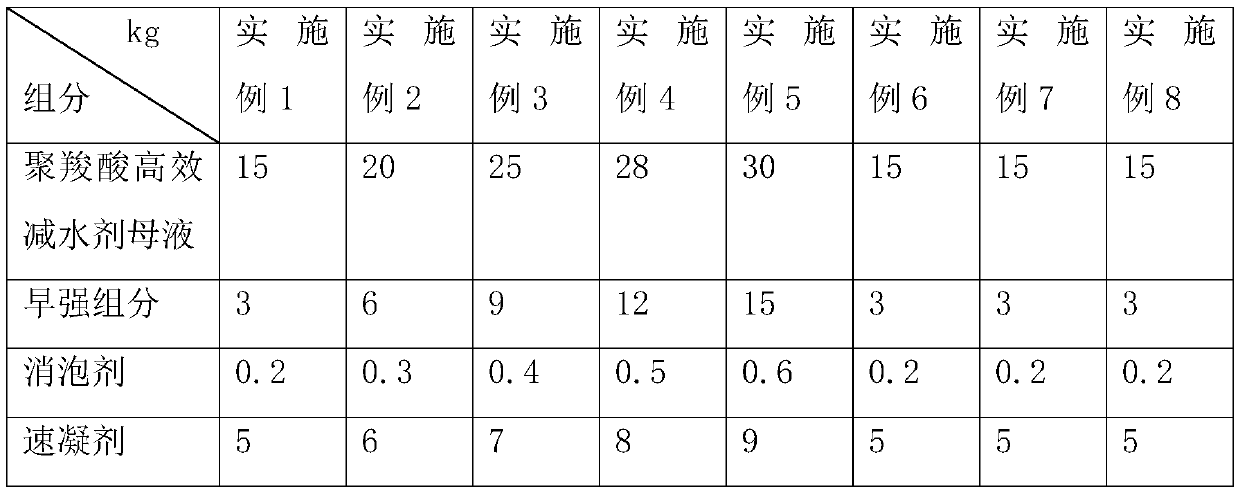

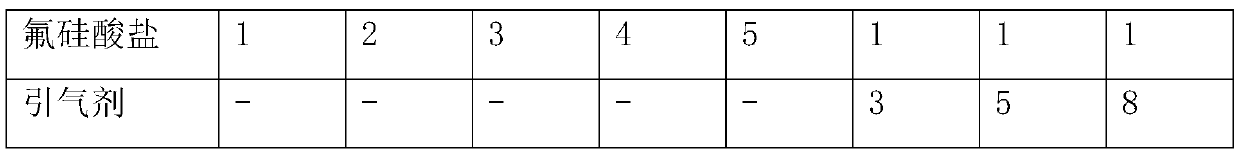

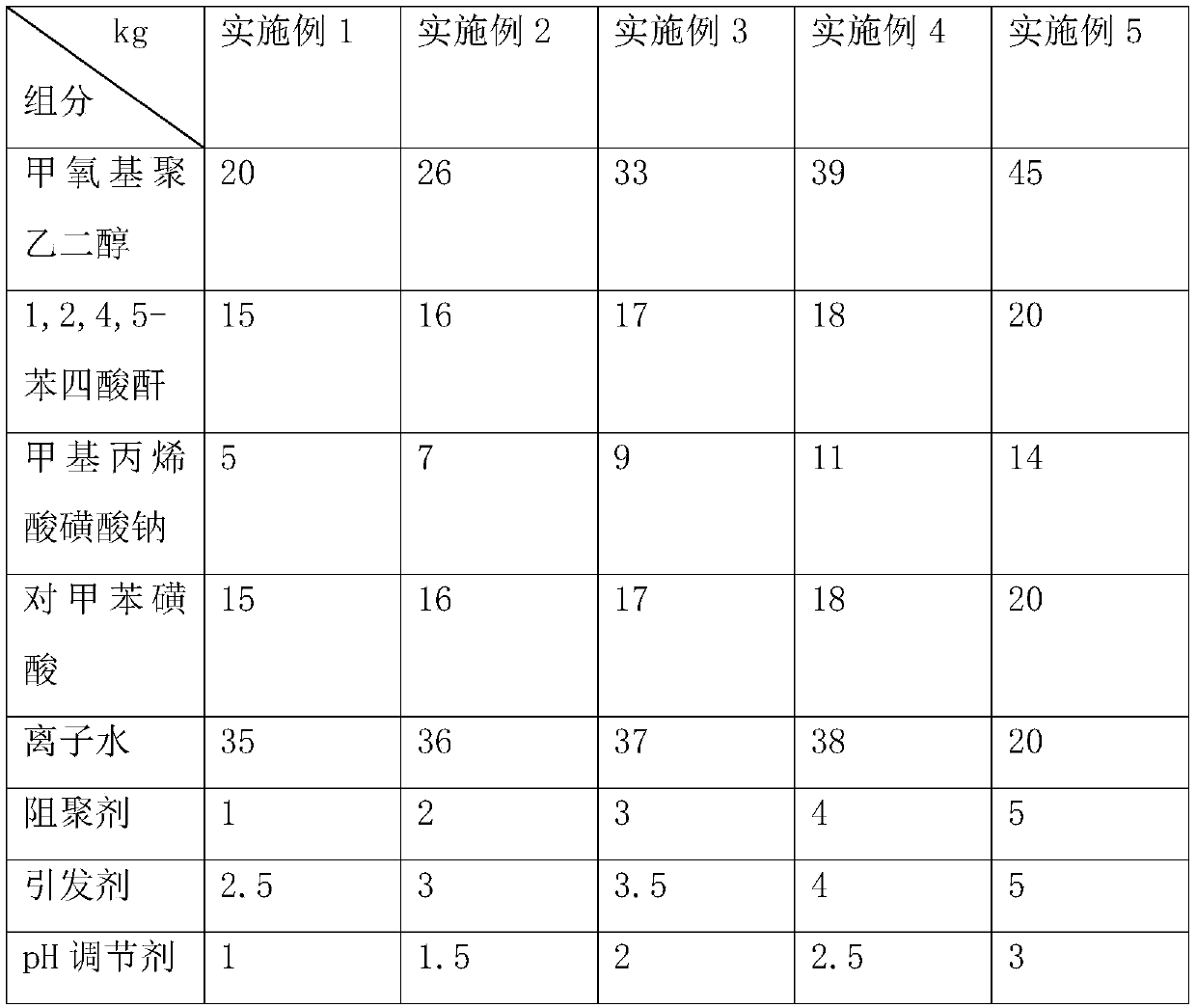

Method used

Image

Examples

preparation example 1-3

[0046] In preparation example 1-3, the rosin resin is selected from the rosin resin whose article number is 422 sold by Jiangxi Jason Resin Co., Ltd., and the sodium gluconate is selected from the sodium gluconate whose article number is 002 sold by Jinan Xinlei Chemical Technology Co., Ltd., lignin sulfonate Calcium acid is selected from the calcium lignosulfonate model MG-3 sold by Shanghai Yunzhe New Material Technology Co., Ltd.

preparation example 1

[0047] Preparation Example 1: Add 7kg of sodium hydroxide to 20kg of water, heat up to 80°C, add 7.5kg of rosin resin under stirring, react for 2 hours, and dilute with hot water at 40°C until it is clear and transparent, without turbidity and precipitation After confirming that the reaction is complete, add 8.5kg sodium gluconate, 4.8kg diethanolamine, 3.2kg concentration of 4% polyvinyl alcohol solution and 3kg calcium lignosulfonate in turn, and stir and mix evenly.

preparation example 2

[0048] Preparation Example 2: Add 11kg of sodium hydroxide to 28kg of water, heat up to 85°C, add 12.5kg of rosin resin under stirring, react for 2.5h, dilute with 50°C hot water until clear, transparent, free of turbidity, Precipitate, after confirming that the reaction is complete, add 12kg sodium gluconate, 5.5kg diethanolamine, 4.4kg polyvinyl alcohol solution with a concentration of 4% and 5kg calcium lignosulfonate in sequence, and stir and mix evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com