Geopolymer based on printing and dyeing sludge and heat-preservation sound-insulation humidity-adjusting plate

A geopolymer, printing and dyeing sludge technology, applied in thermal insulation, water pollutants, sludge treatment, etc., can solve the problems of high water content, high content of harmful substances, unsuitable production, etc., to eliminate contact with organic matter, good application performance, and the effect of facilitating resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The raw materials for the preparation of thermal insulation, sound insulation and humidity control panels based on printing and dyeing sludge in this example include:

[0058] Modified printing and dyeing sludge 45g;

[0059]

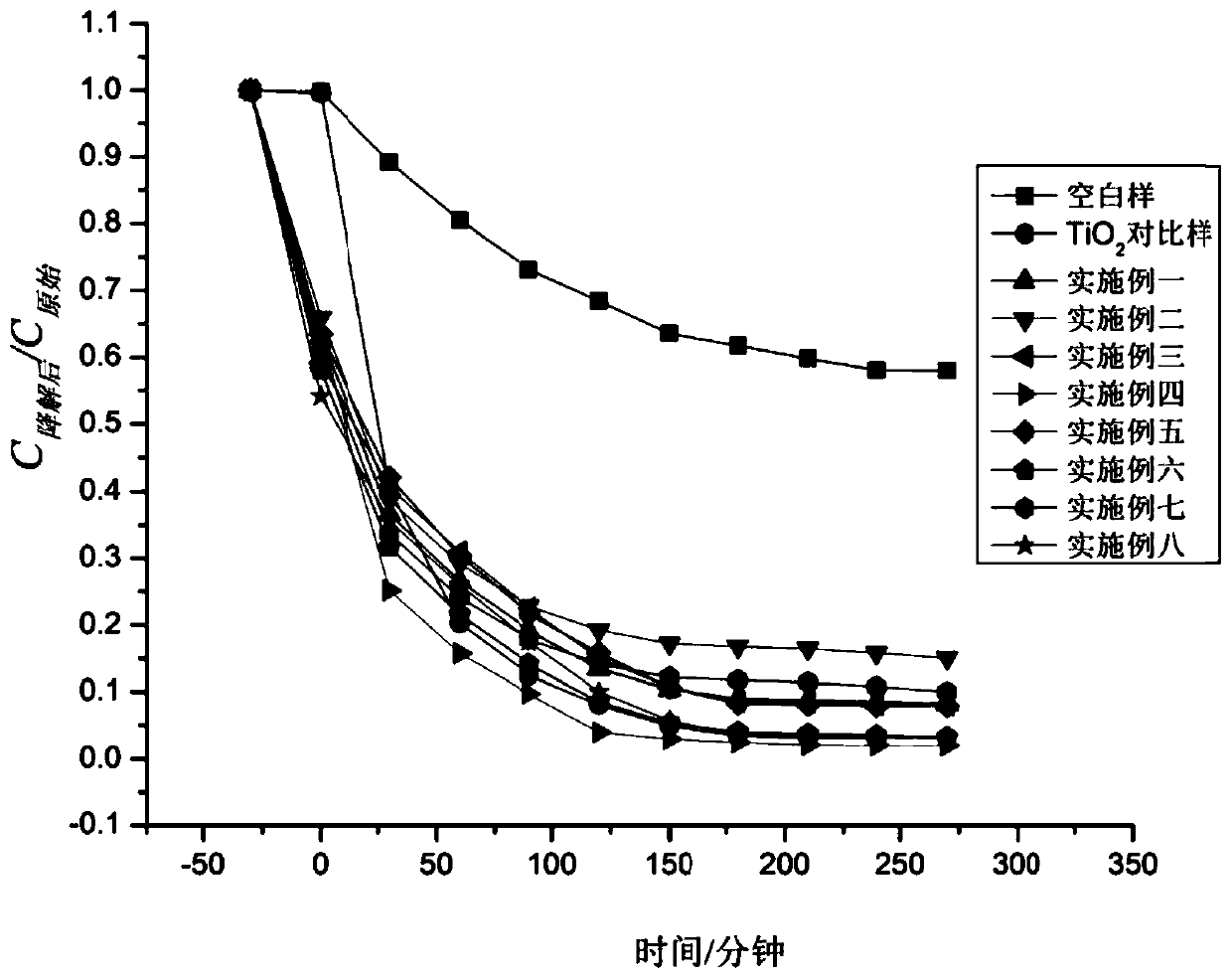

[0060] In this example, the modified printing and dyeing sludge is prepared according to the following steps: According to the mass ratio of 1:1, the printing and dyeing sludge is fully mixed with the fly ash particles loaded with N-doped titanium dioxide, and an appropriate amount (accounting for Sludge amount 3-5wt%) water, control the stirring speed 500-800rpm / min, and add ultraviolet light (wavelength 200-400nm) to catalyze during the stirring process, obtain the desired modified printing and dyeing sludge.

[0061] The method for preparing the thermal insulation, sound insulation and humidity control board based on printing and dyeing sludge described in this embodiment includes the following steps:

[0062] (1) Get the wood powder of se...

Embodiment 2

[0067] The raw materials for the preparation of thermal insulation, sound insulation and humidity control panels based on printing and dyeing sludge in this example include:

[0068]

[0069] In this example, the modified printing and dyeing sludge is prepared according to the following steps: According to the mass ratio of 2:1, the printing and dyeing sludge is fully mixed with the fly ash particles loaded with N-doped titanium dioxide, and an appropriate amount (accounting for Sludge amount 3-5wt%) water, control the stirring speed 500-800rpm / min, and add ultraviolet light (wavelength 200-400nm) to catalyze during the stirring process, obtain the desired modified printing and dyeing sludge.

[0070] The method for preparing the thermal insulation, sound insulation and humidity control board based on printing and dyeing sludge described in this embodiment is the same as that in Embodiment 1.

Embodiment 3

[0072] The raw materials for the preparation of thermal insulation, sound insulation and humidity control panels based on printing and dyeing sludge in this example include:

[0073]

[0074]

[0075] In this example, the modified printing and dyeing sludge is prepared according to the following steps: According to the mass ratio of 3:1, the printing and dyeing sludge is fully mixed with the fly ash particles loaded with N-doped titanium dioxide, and an appropriate amount (accounting for Sludge amount 3-5wt%) water, control the stirring speed 500-800rpm / min, and add ultraviolet light (wavelength 200-400nm) to catalyze during the stirring process, obtain the desired modified printing and dyeing sludge.

[0076] The method for preparing the thermal insulation, sound insulation and humidity control board based on printing and dyeing sludge described in this embodiment is the same as that in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com