Patents

Literature

63results about How to "Meet huge demand" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cloud computing platform-based interactive analysis system and method for transcriptome project with reference genome

InactiveCN107368704AImprove the level of comprehensive managementComprehensive interactive analysisProteomicsGenomicsItem selectionCloud computing

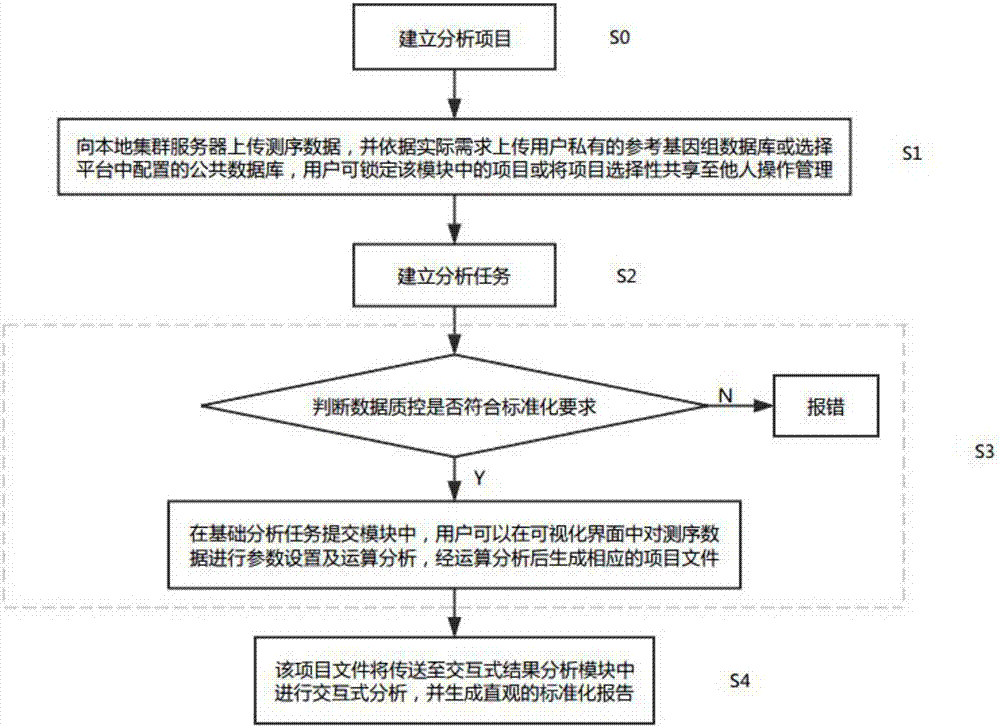

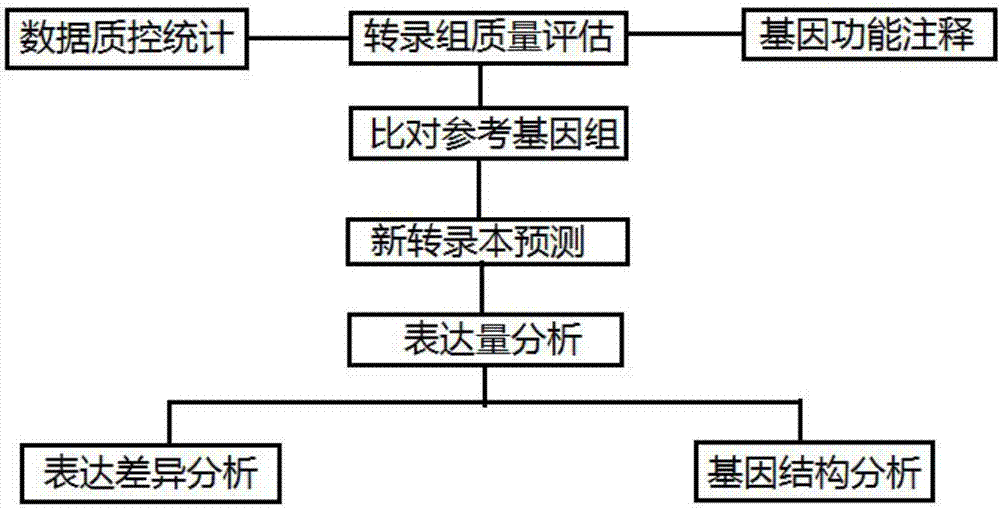

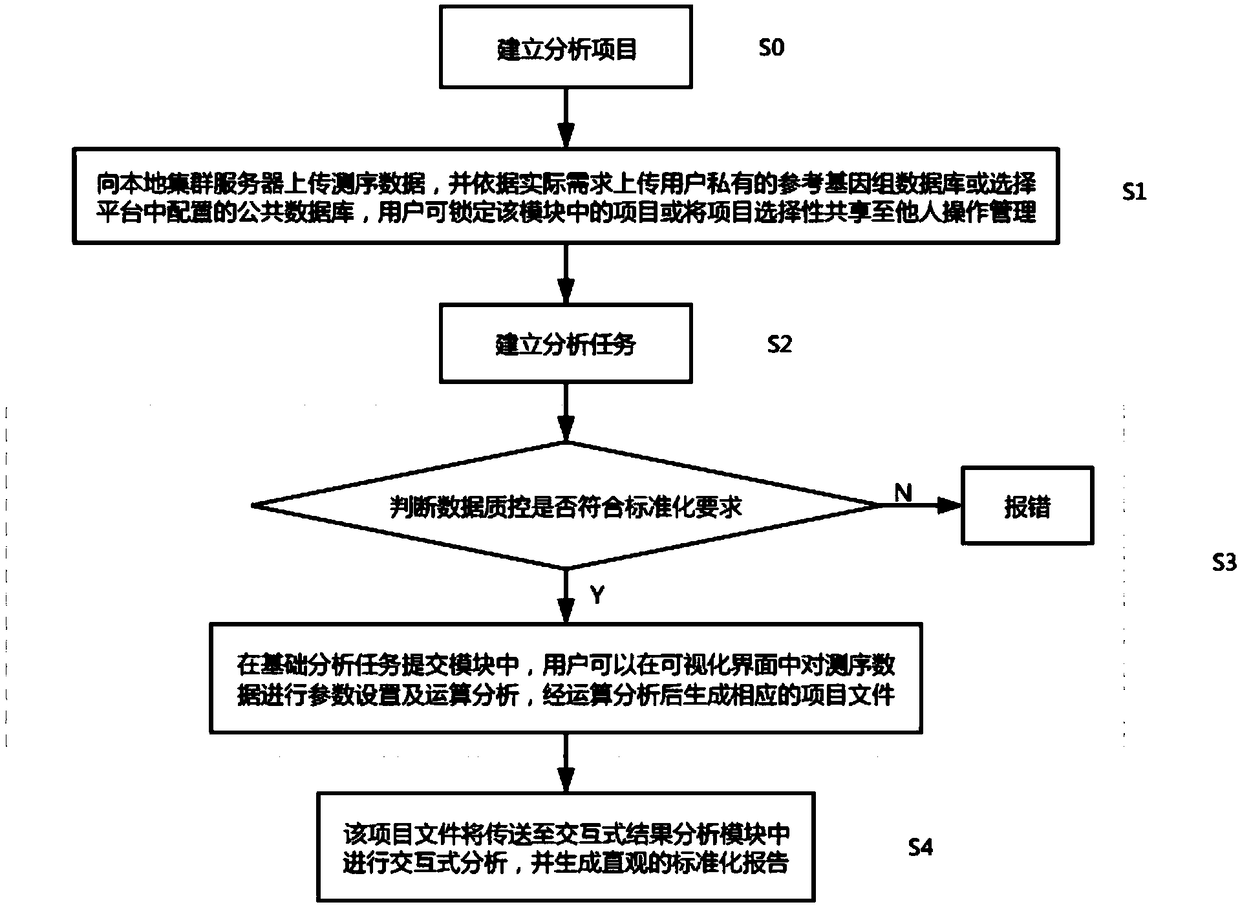

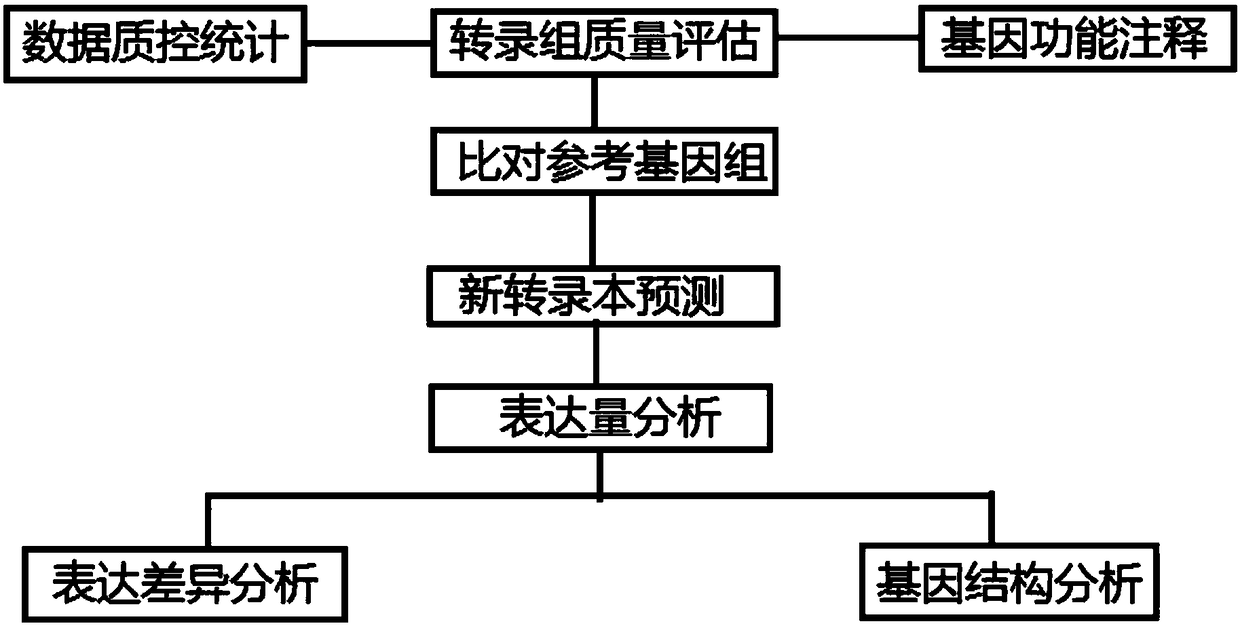

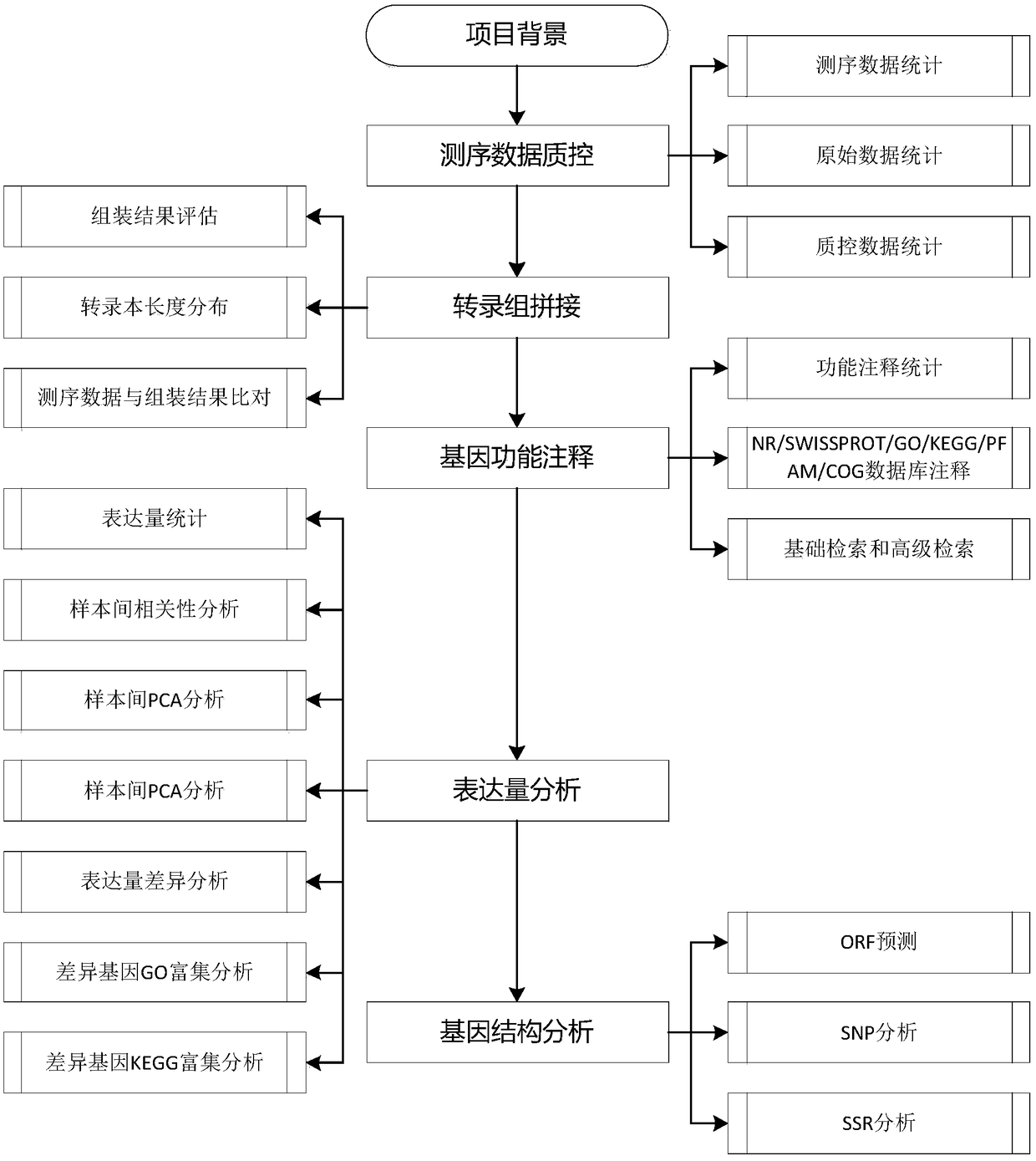

The invention discloses a cloud computing platform-based interactive analysis system and method for a transcriptome project with a reference genome. In a project management module, sequencing data is uploaded to a local cluster server after an analysis project is established; a private reference genome database of a user is uploaded or a public database configured in a platform is selected according to an actual demand; and the user locks the project in the module or selectively shares the project to others for operation and management. In a basic analysis task submitting module, the user performs parameter setting and calculation analysis on the sequencing data in a visual interface; before the calculation analysis, whether data quality control meets standardized requirements or not is prejudged; if the requirements are not met, error report information is directly returned; if the requirements are met, the calculation analysis of specified parameters is carried out; a corresponding project file is generated after the calculation analysis; the project file is transmitted to an interactive result analysis module for performing interactive analysis; and an intuitive standardized report is generated.

Owner:上海桑格信息技术有限公司

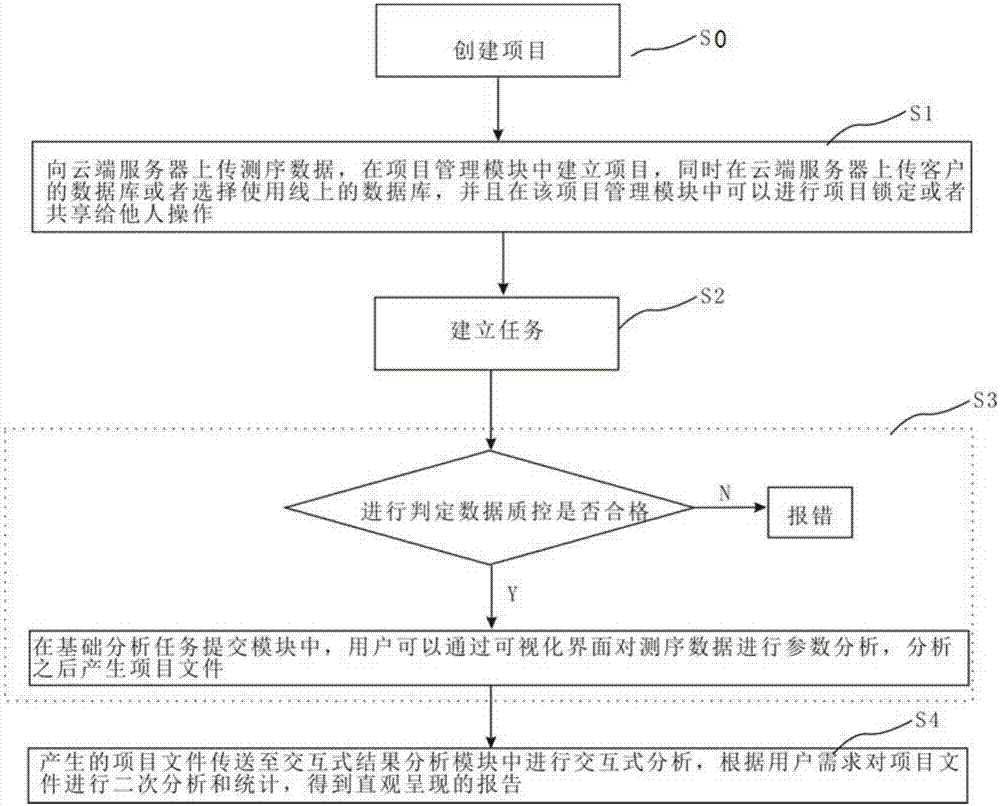

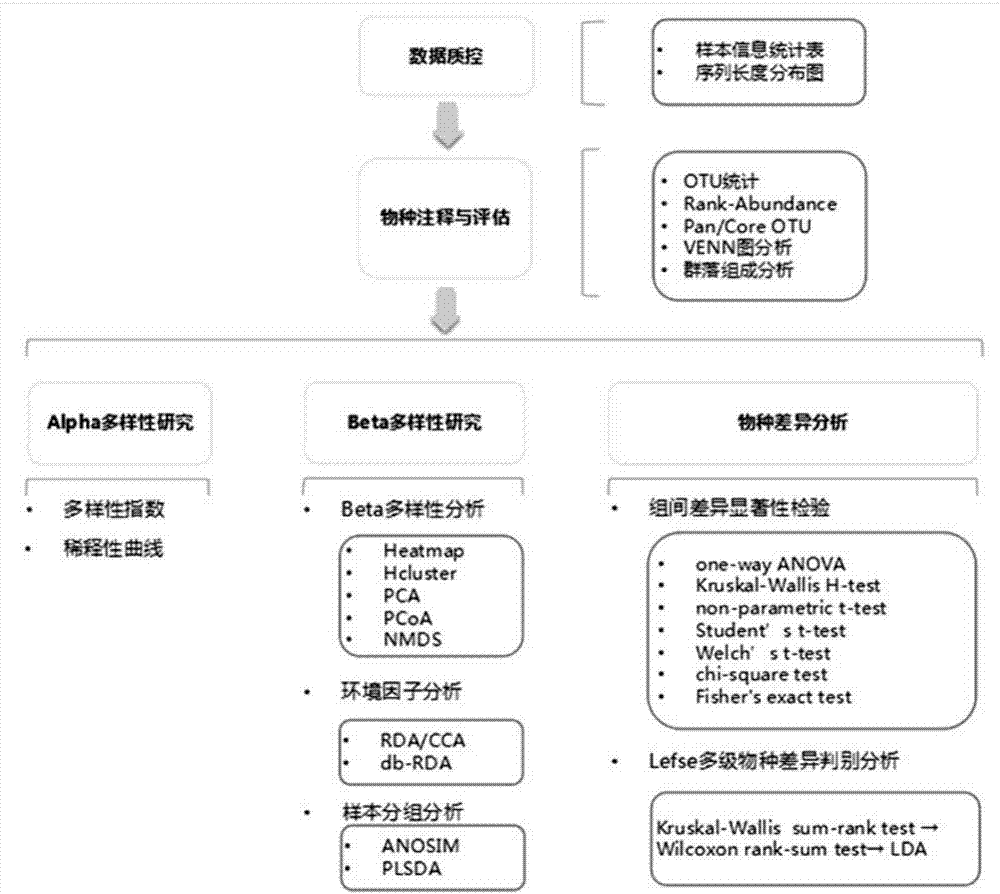

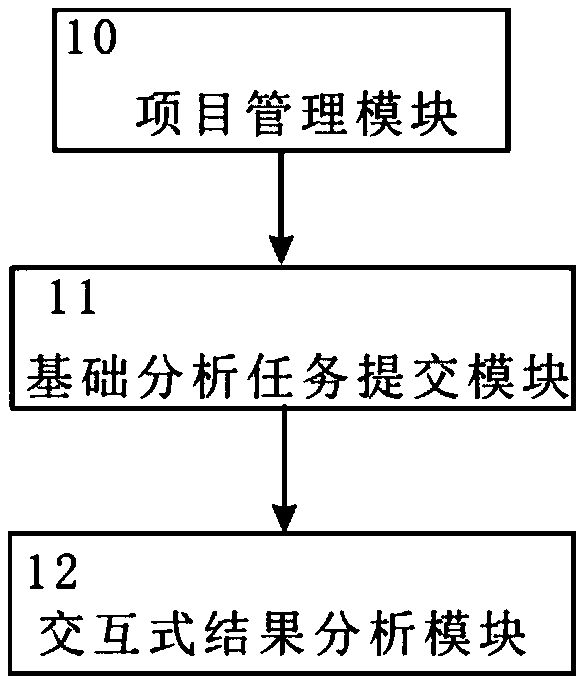

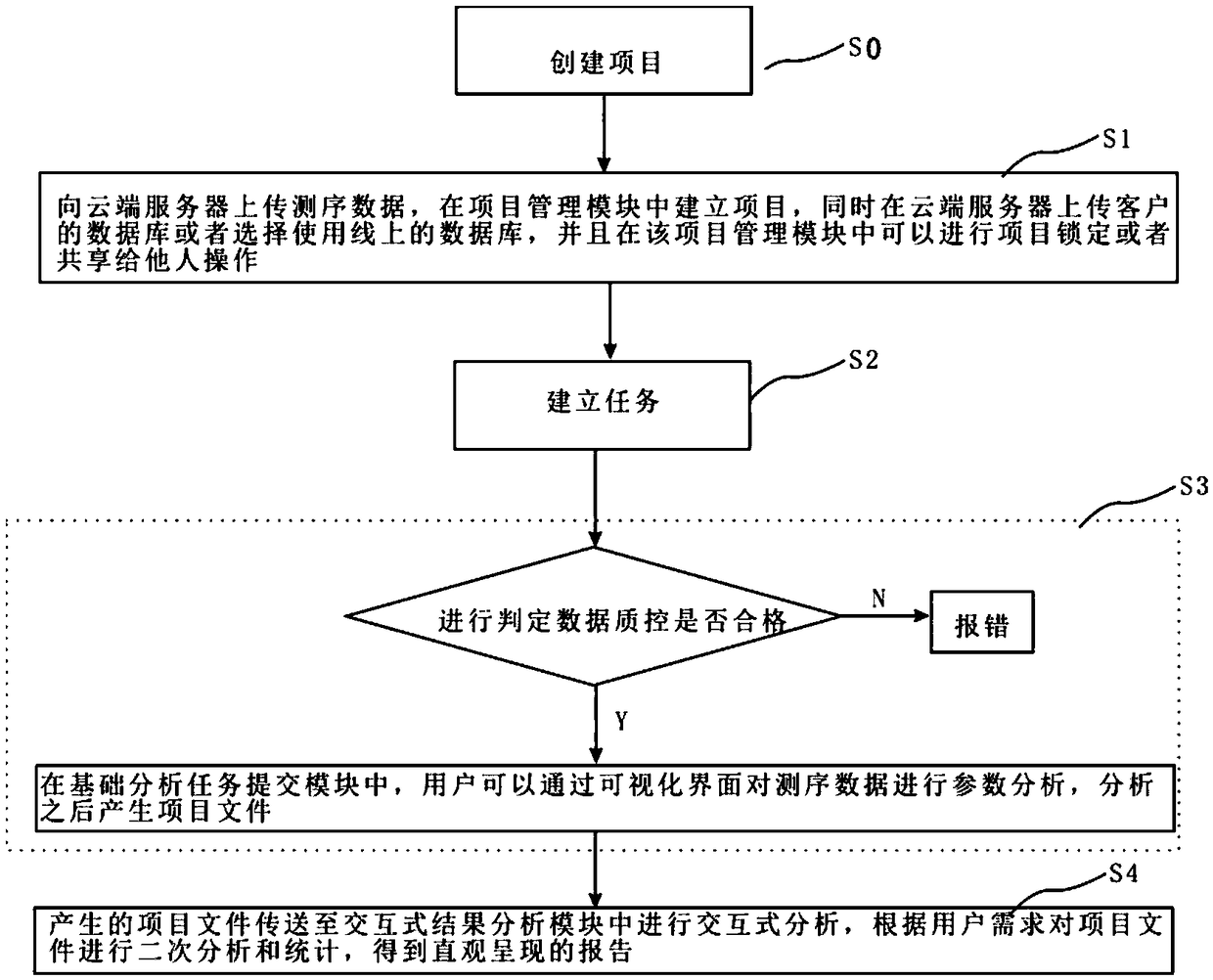

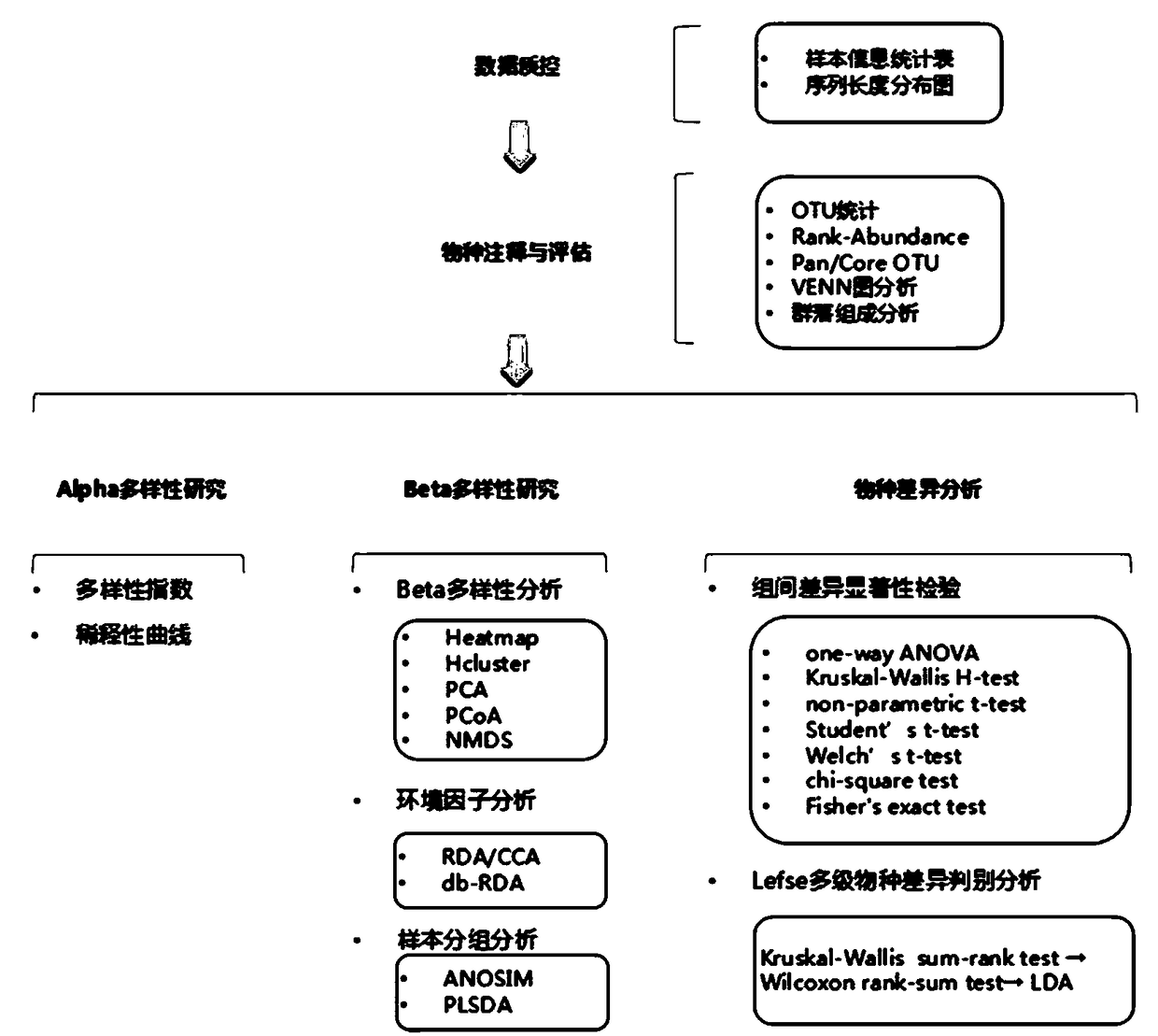

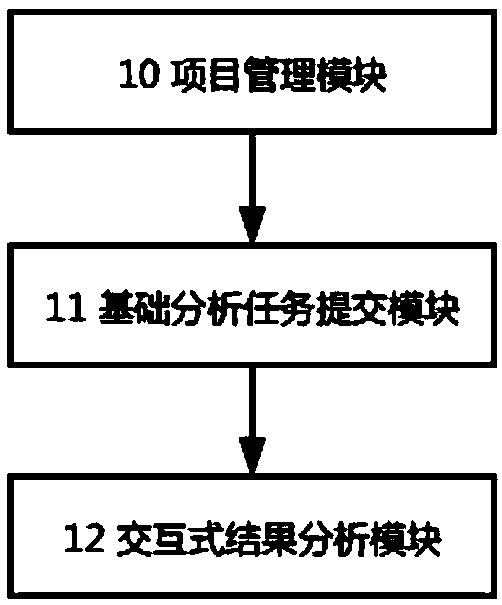

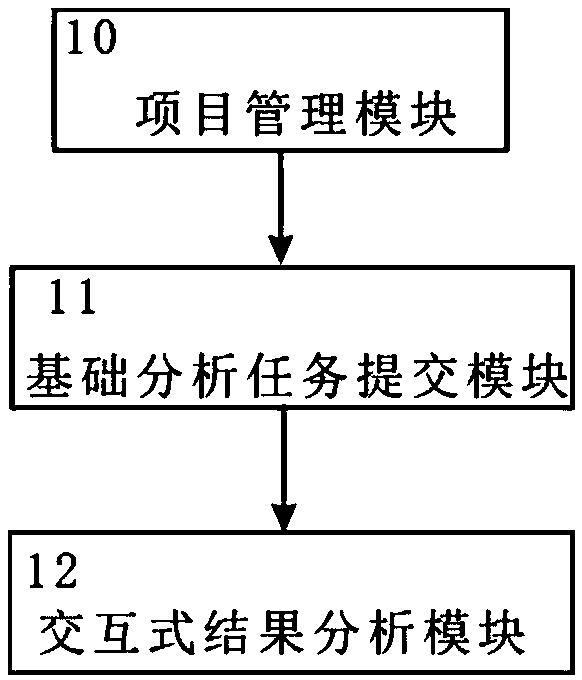

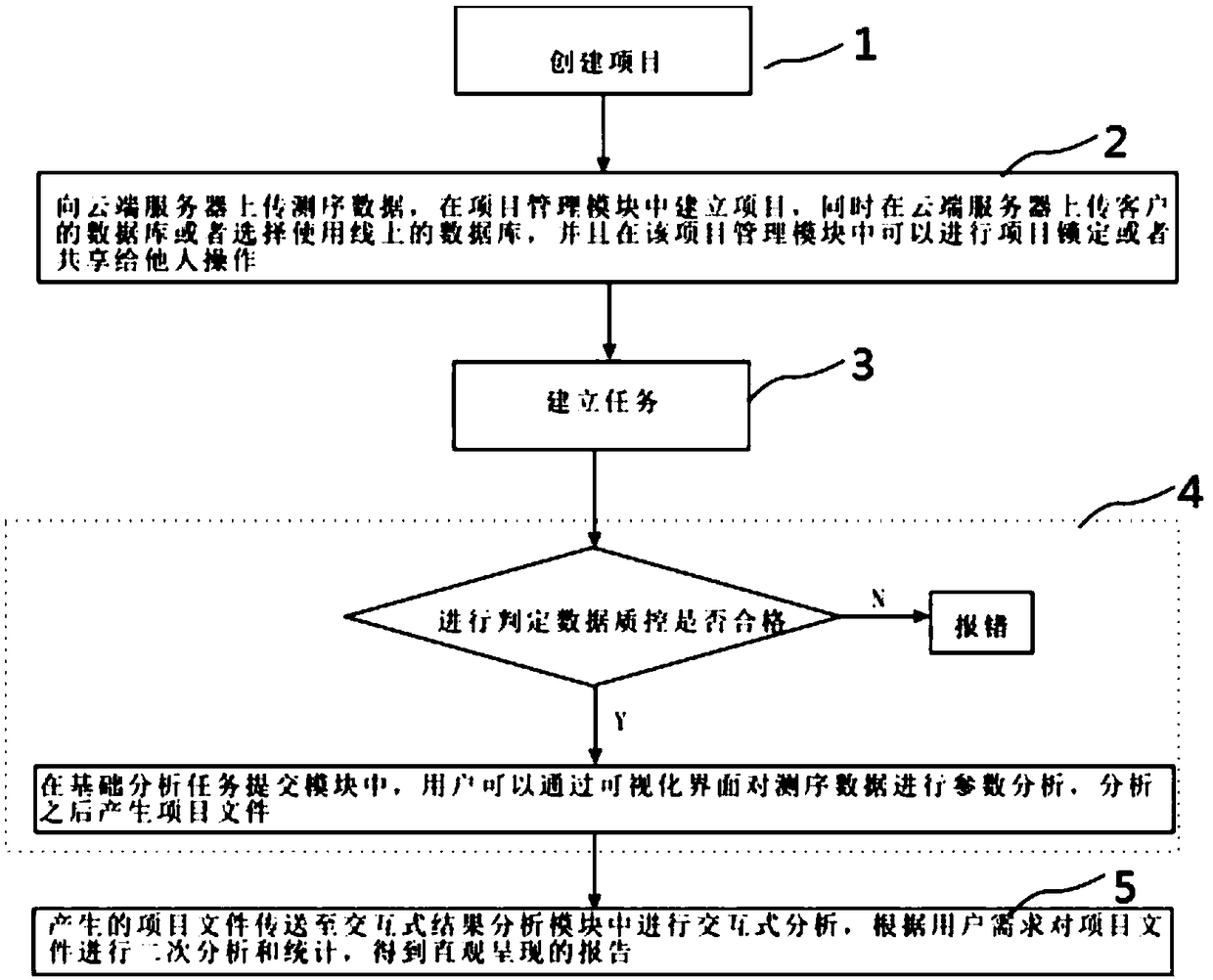

Computation cloud platform-based microbial diversity interaction analysis system and method thereof

InactiveCN107368700AMeet huge demandMeet needsData visualisationSpecial data processing applicationsProject managementMicrobial diversity

The invention discloses a computation cloud platform-based microbial diversity interaction analysis system and method thereof. The system comprises a project management module, a basic analysis task submission module and an interactive result analysis module. The method comprises the following steps of: firstly uploading sequencing data to a local cluster server, establishing a project in the project management module, uploading a database of customers to the local cluster server or selecting to use an online database, and locking the project in the project management module or sharing the project to other users to be operated; in the basic analysis task submission module, carrying out parameter analysis on the sequencing data by a user through a visual interface and generating a project file after the analysis; before the analysis, judging whether data quality control is qualified or not, if the judging result is positive, carrying out the parameter analysis, and otherwise, directly returning an error; and transmitting the generated project file to the interactive result analysis module to carry out interactive analysis until an intuitively displayed report is obtained.

Owner:上海桑格信息技术有限公司

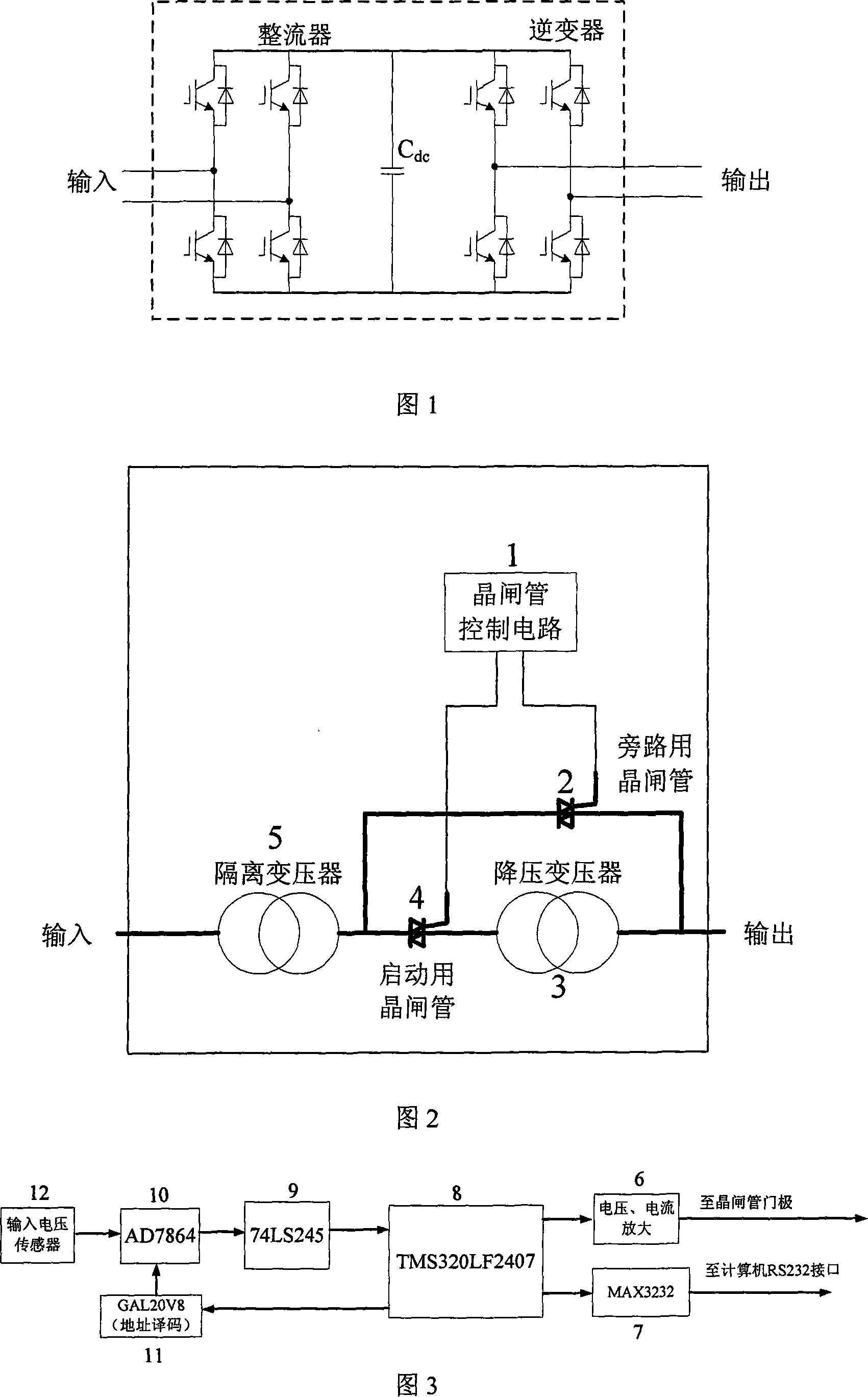

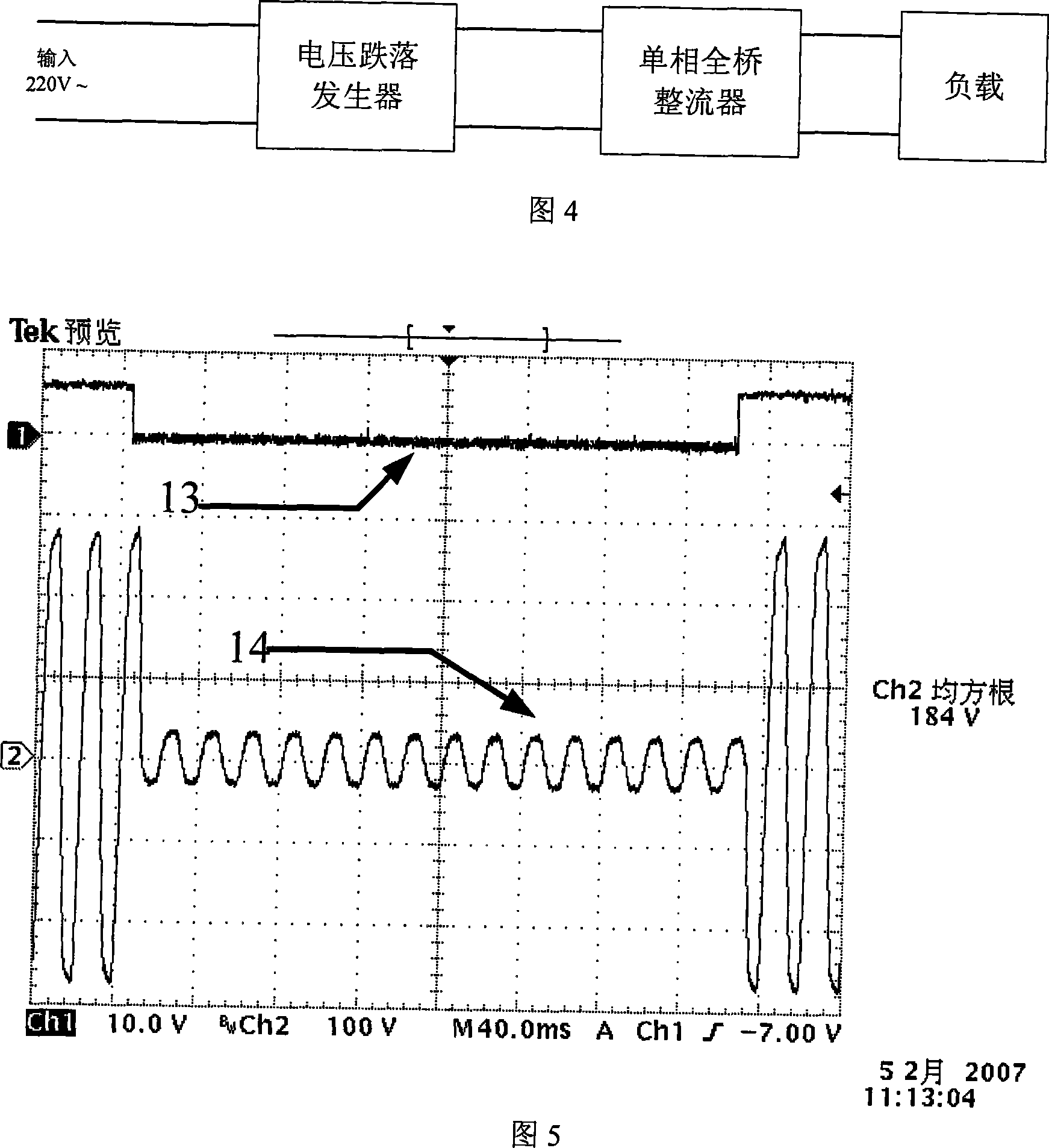

Electric network electric voltage drop generator

InactiveCN101119074AAchieve separationImprove securityConversion without intermediate conversion to dcThyratronVoltage drop

The present invention relates to a power network voltage drifting-down generator, comprising a thyristor control circuit(1), an isolating transformer(5), a step-down transformer(3), a bypassing thyristor(2), a starting thyristor(4) and a thyristor drive circuit. The thyristor control circuit(1) is used for detecting the input voltage signal, deciding the continuity signals of the reverse parallel connection thyristor. The bypassing thyristor(2) and the starting thyristor(4), sending the actuating signal of the reverse parallel connection thyristor at the zero crossing point of the input signal, the running state of the step-down transformer(3) is controlled through the bypassing thyristor(2) and the starting thyristor(4), changing the value of the input voltage. The present invention is capable of realizing the instant change to the input voltage.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI +1

Fireproof insulation board of aerated concrete of B02-level light sand

The invention discloses a fireproof insulation board of aerated concrete of B02-level light sand. The constituents and weight percentages of the fireproof insulation board are as follow: 45-55% of quartz sand, 12-16% of lime, 24-37% of cement, 5% of gypsum, 0.25-0.35% of aluminite powder and 0.2-0.6% of composite admixture, wherein the composite admixture is admixture with composite stabilizing, toughening and waterproof functions, and the constituents and weight percentages are as follow: 25-30% of sodium abietate, 22-26% of chlorinated paraffin, 24-28% of petroleum ether and 20-25% of organo-siloxane. The fireproof insulation board has the advantages that the fireproof insulation board compensates the disadvantages and defects of the prior art, overcomes the production difficulties, andimproves the casting stability when reducing dry density of the aerated concrete product of the sand, so as to conveniently transport and construct the product, and meet huge demands of the construction market and energy conservation and environmental protection requirements of people on building materials in cities.

Owner:天津滨海天筑永利建材有限公司

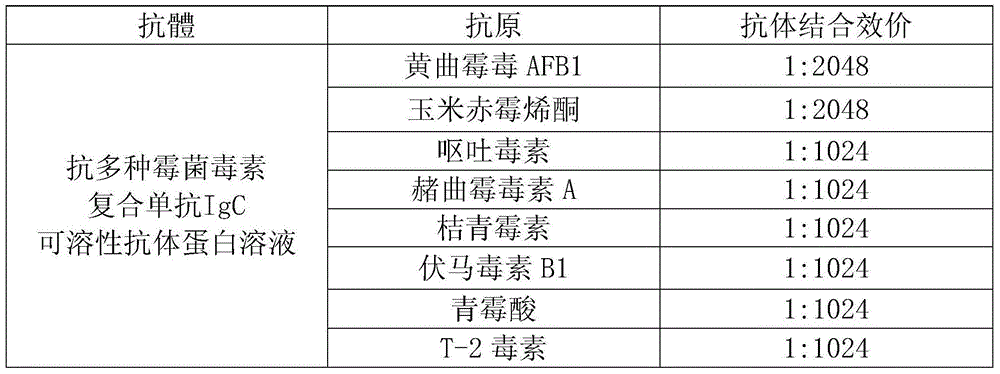

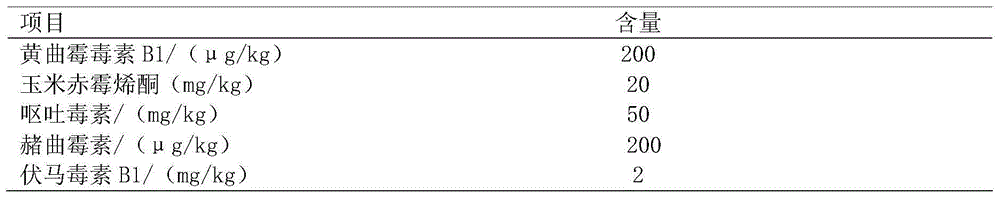

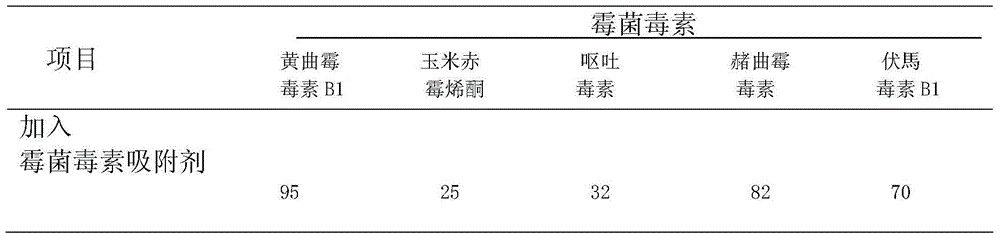

Genetic engineering recombinant high-purity anti-mycotoxin monoclonal antibody for inhibiting and killing mycotoxin as well as composite monoclonal antibody preparation method and combined preparation thereof

The invention relates to a genetic engineering recombinant high-purity anti-mycotoxin monoclonal antibody for inhibiting and killing mycotoxin as well as a composite monoclonal antibody preparation method and a combined preparation thereof. The preparation method comprises the following steps: screening mycotoxin; connecting the mycotoxin with vector carrier to prepare immune antigen; performing immune and cell fusion to prepare a hybridoma cell; performing gene cloning, constructing anti-mycotoxin monoclonal antibody Ig and expressing in engineering bacteria; fermenting and amplifying recombinant engineering bacteria, culturing to prepare bacteria of the anti-mycotoxin monoclonal antibody Ig; performing cell crushing, filtering and removing bacteria and viruses, centrifuging, purifying and performing chromatography to prepare anti-mycotoxin monoclonal antibody Ig and soluble antibody protein of composite monoclonal antibody IgC. The anti-mycotoxin monoclonal antibody and the composite monoclonal antibody IgC can be used as a grain mycotoxin remover, feed components and can be prepared into an animal drug; the anti-mycotoxin monoclonal antibody Ig, the composite monoclonal antibody IgC and the combined preparation thereof can be used for effectively degrading the mycotoxin in feed and food, preventing and treating mycotoxin toxic disorders.

Owner:SHENZHEN JASON INTELLIGENT BIOTECH CO LIMLTED PRC

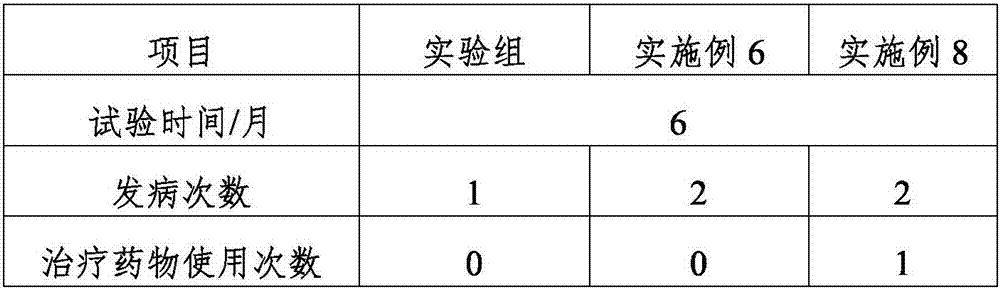

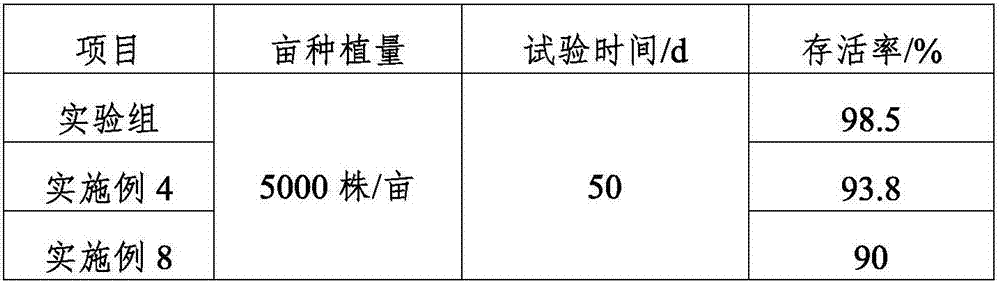

Efficient planting method for mulberry

InactiveCN106857161AIncrease productionStrong medicineBiocideMagnesium fertilisersPest controlSurvival rate

The invention relates to the technical field of planting, in particular to an efficient planting method for mulberry. The method comprises the following steps of seedling growing, transplanting, pest control and field management. By adopting the planting method, planted mulberry is high in disease resistance and insect resistance, high in yield and strong in pesticide effect, compared with the acre yield of mulberry planted through a traditional method, the yield of folium mori can be increased by 28% or above, the yield of mulberry fruits can be increased by 13.2% or above, and due to the planting method, the acre yield of mulberry trees is effectively improved; the survival rate of seedlings is increased by 9.4% compared with a traditional method; on the basis of the scientific planting method, effective components of mulberry trees can be effectively improved, the pesticide effect is improved, and the requirement of the current market for a large number of mulberry trees is met.

Owner:广西山水牛畜牧业有限责任公司

Internal coating anticorrosion process of pipe for oil exploitation

InactiveCN103084324AReduce mining costsImprove fluid efficiencyPretreated surfacesCoatingsEpoxyAbrasive blasting

The invention discloses an internal coating anticorrosion process of a pipe for oil exploitation. The process includes the following steps that (1) the pipe is placed in a hot cleaning furnace, and various greasy dirt and impurities on the inner wall of the pipe are carbonized; (2) the inner wall of the pipe is subjected to surface treatment by two-stage abrasive blasting, treatment conditions of the inner wall are fully and automatically checked, and the inner wall is blown after the treatment is qualified; (3) an A component and B component of double-component epoxy coating TC3000I are mixed according to the proportion of an instruction book, the mixed coating is used for performing one-time spray coating on the inner wall of the pipe, and solidification is performed at normal temperatures; and (4) leak point detection is performed after solidification, and if a leak point is absent, the pipe is qualified. By means of the pipe subjected to internal coating anticorrosion by the internal coating anticorrosion process, the fluid efficiency in an oil well pipe can be improved by above 25%, simultaneously, abrasive resistance, chemical resistance and corrosion resistance of the pipe can be improved, the pipe can be used for a long time at the temperature below 120 DEG C, the application range of the pipe is further widened, and positive effects are achieved on reducing oil exploitation costs.

Owner:SHANGHAI TUBE COTE PETROLEUM PIPE COATING

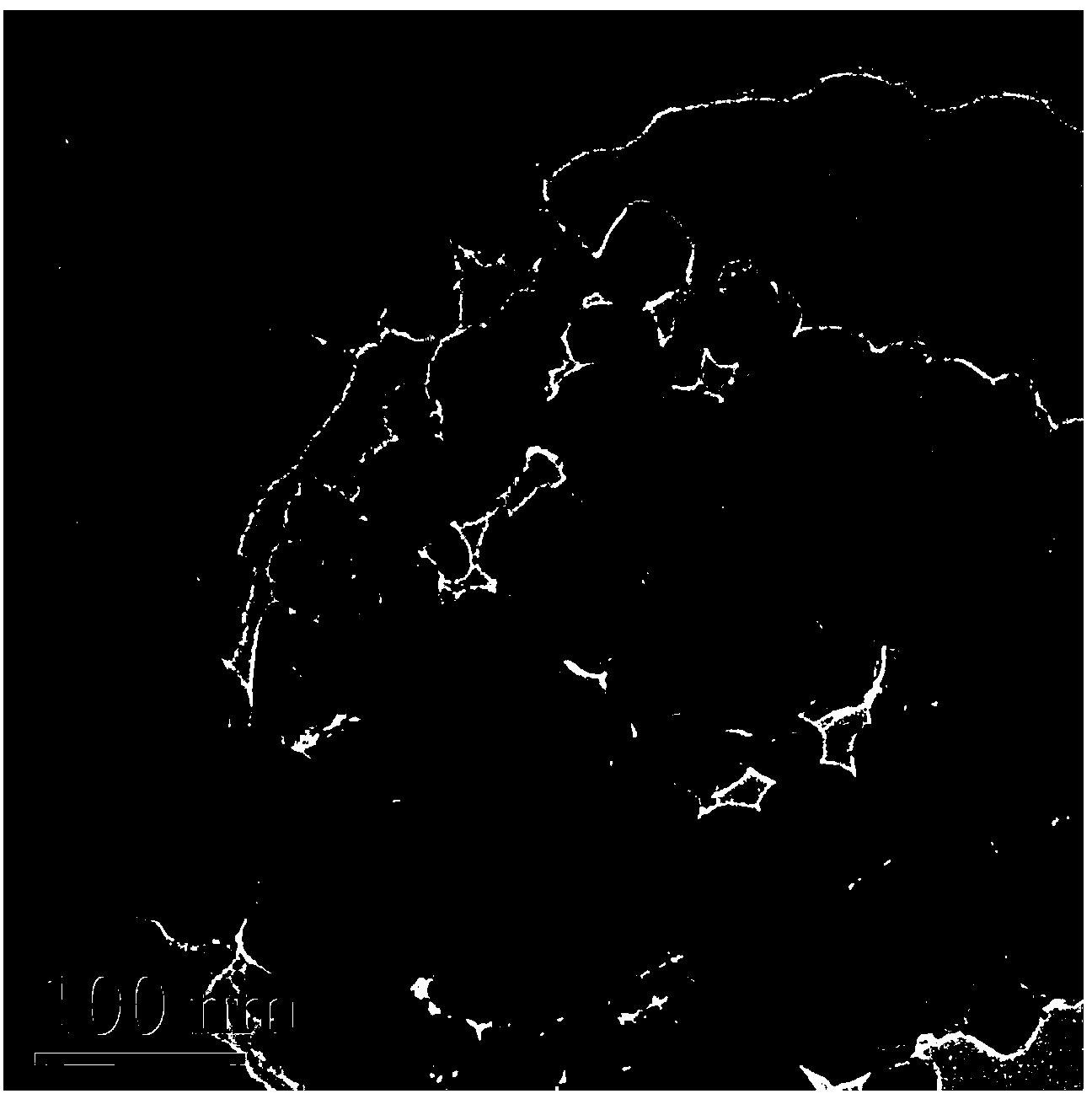

Preparation method of dye-sensitized solar cell platinum loaded silicon carbide counter electrodes

ActiveCN103413687ARelieve stressReduce dependenceLight-sensitive devicesPhotovoltaic energy generationUltrasonic dispersionSizing

The invention discloses a preparation method of dye-sensitized solar cell platinum loaded silicon carbide counter electrodes. The preparation method comprises the steps of (1) preparing Pt-SiC composite counter electrode materials: respectively preparing the H2PtCl6 solution and the SiC alcoholic solution, conducting ultrasonic mixing on the H2PtCl6 solution and the SiC alcoholic solution, adjusting the pH value, conducting microwave heating after ultrasonic dispersion is carried out, conducting washing, filtering and drying, conducting heat treatment in the inert atmosphere, and obtaining the Pt-SiC composite counter electrode materials, and (2) building a Pt-SiC counter electrode thin film: washing and drying FTO conducting glass, adding the Pt-SiC composite counter electrode materials into a dispersing agent, conducting dispersing processing to obtain a counter electrode catalytic material sizing agent, coating the conducting glass with the counter electrode catalytic material sizing agent to form the Pt-SiC counter electrode thin film, and conducting heat treatment in the inert atmosphere to obtain the platinum loaded silicon carbide counter electrodes. The preparation method is low in building cost, simple in operation process, low in energy consumption, environmentally friendly and high in compatibility with the photo-anode preparation technology. The precious metal Pt electrodes can be replaced by the Pt loaded silicon carbide counter electrodes, and the Pt loaded silicon carbide counter electrodes can be applied to dye-sensitized solar cell devices.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

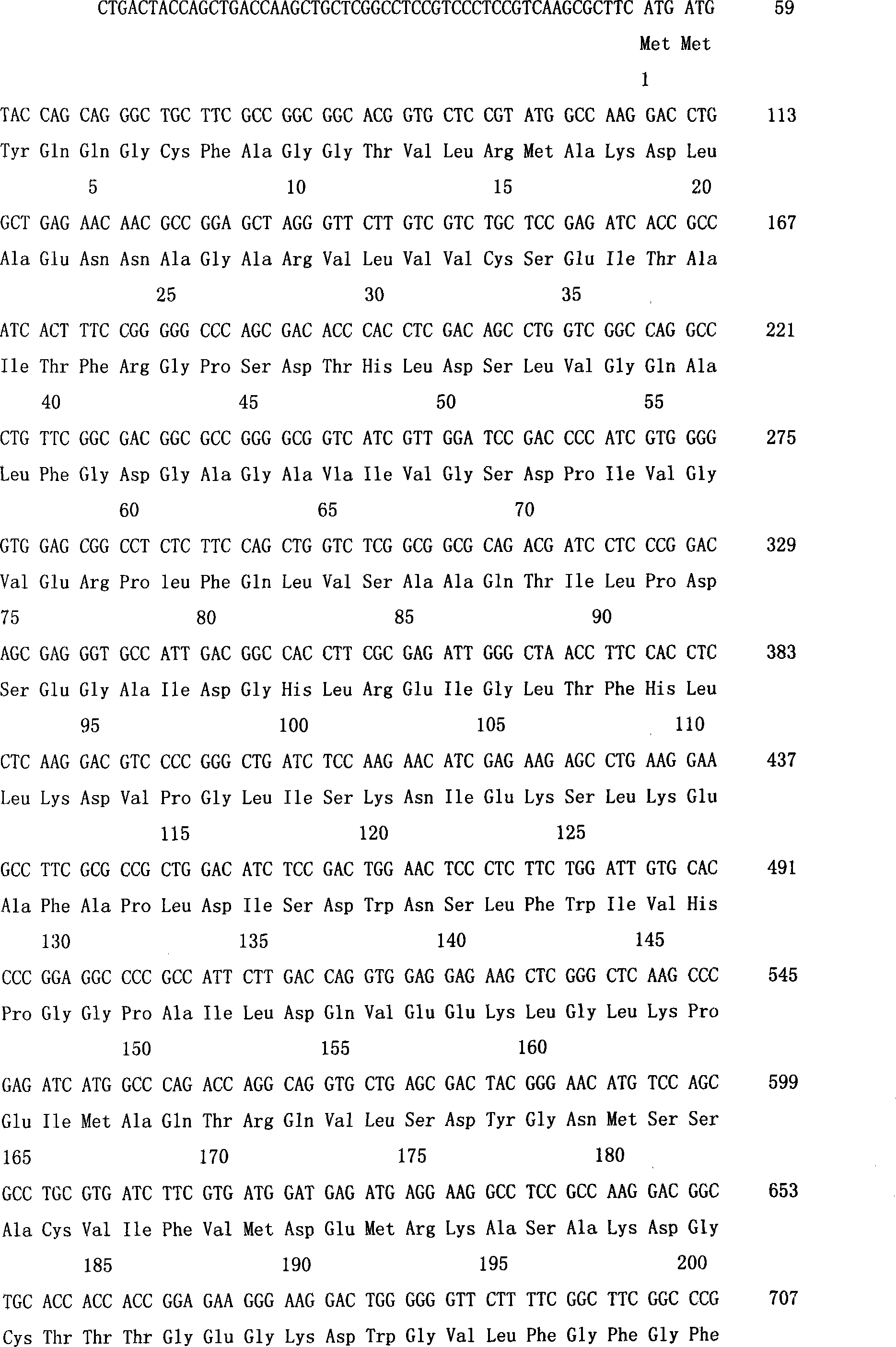

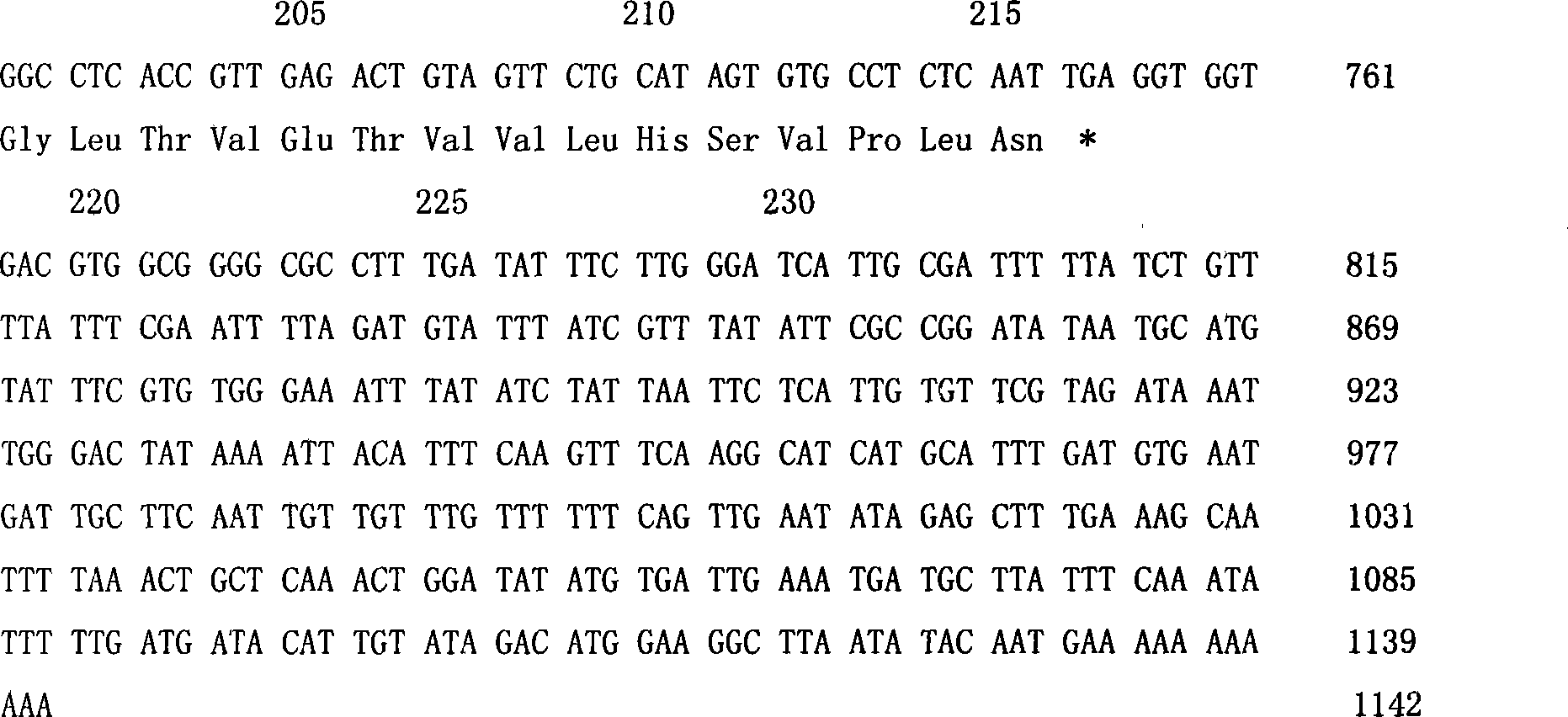

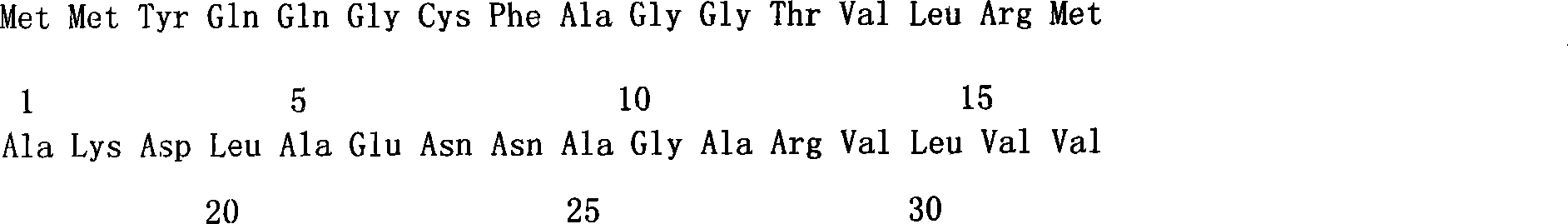

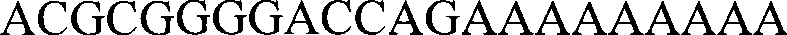

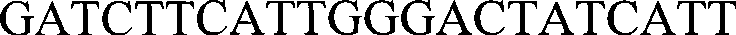

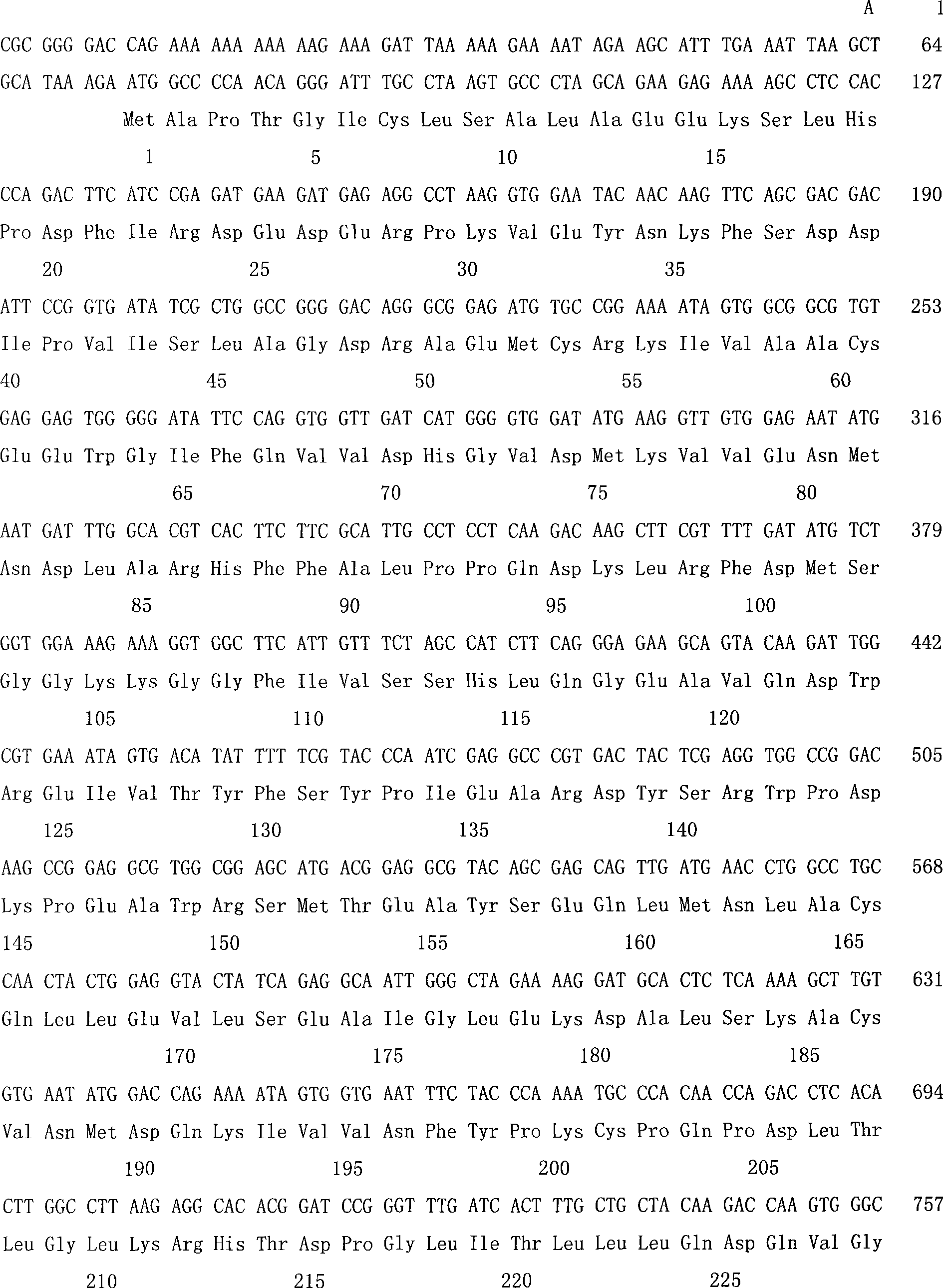

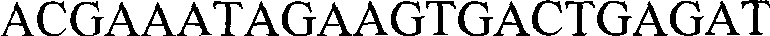

Davilpepper tryptophan decarboxylase protein coded sequence

InactiveCN101012462AIncrease productionMeet huge demandFermentationVector-based foreign material introductionRibonucleotide synthesisGene engineering

The invention discloses a davilpepper tryptophan decarboxylase protein coding sequence in the gene engineering domain, which is characterized by the following: coding the ribonucleotide sequence with 70% consanguinity with 154-1653rd in the SEQ ID NO.1; crossing 154-1653rd in the SEQ ID NO.1 under 45-55 deg.c.

Owner:SOUTHWEST UNIV

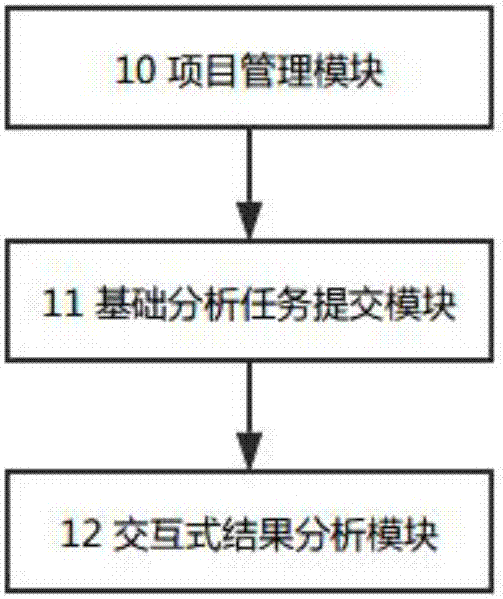

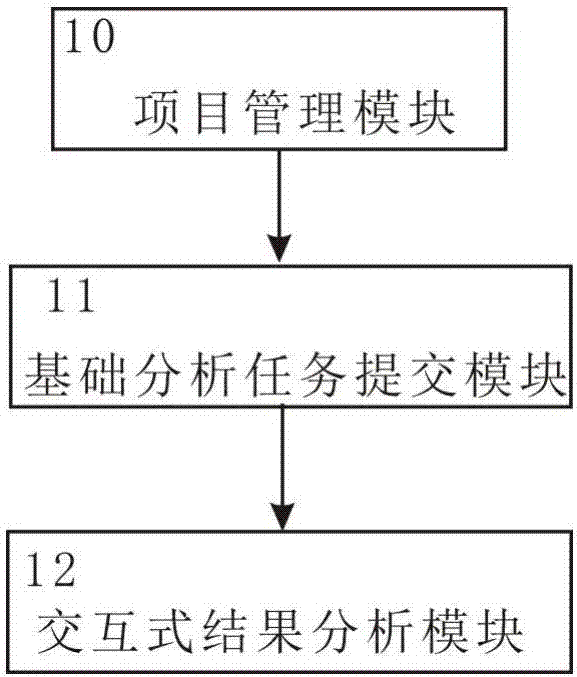

Computing cloud platform-based microbial diversity interactive analysis system and method

The invention discloses a computing cloud platform-based microbial diversity interactive analysis system and method. The system comprises a project management module for viewing and managing project information, a basic analysis task submission module which is used for setting a basic parameter operation task, integrating and packaging results and original data into a corresponding project file according to a preset format, and an interactive result analysis module which is used for generating an analysis result according to a user request and visually displaying the result. According to the system and method of the present invention, a highly integrated data analysis platform is provided by means of cloud computing technology, and a good foundation is laid for basic analysis, advanced analysis and personalized analysis covering microbial diversity analysis.

Owner:上海桑格信息技术有限公司

Interactive analysis system and method for transcriptome project with reference genome based on cloud computing platform

InactiveCN109086567AEasy to dig deepMeet huge demandSpecial data processing applicationsPersonalizationOriginal data

The invention discloses an interactive analysis system and a method of a transcriptome project with a reference genome based on a cloud computing platform. The system comprises a project management module for viewing, editing and managing the detailed information of the project. A basic analysis task submitting module is used for setting parameters of a task, performing operation analysis after submitting, and integrating the output analysis result and the original data to generate a project file according to a preset format; and an interactive result analysis module for further optimizing theanalysis results according to the user's personalized requirements and visually presenting the results. The system and method of the present invention provide a highly integrated data analysis platform by means of cloud computing technology, laying a good foundation for basic analysis, advanced analysis and personalized analysis of a transcriptome project with a reference genome.

Owner:上海桑格信息技术有限公司

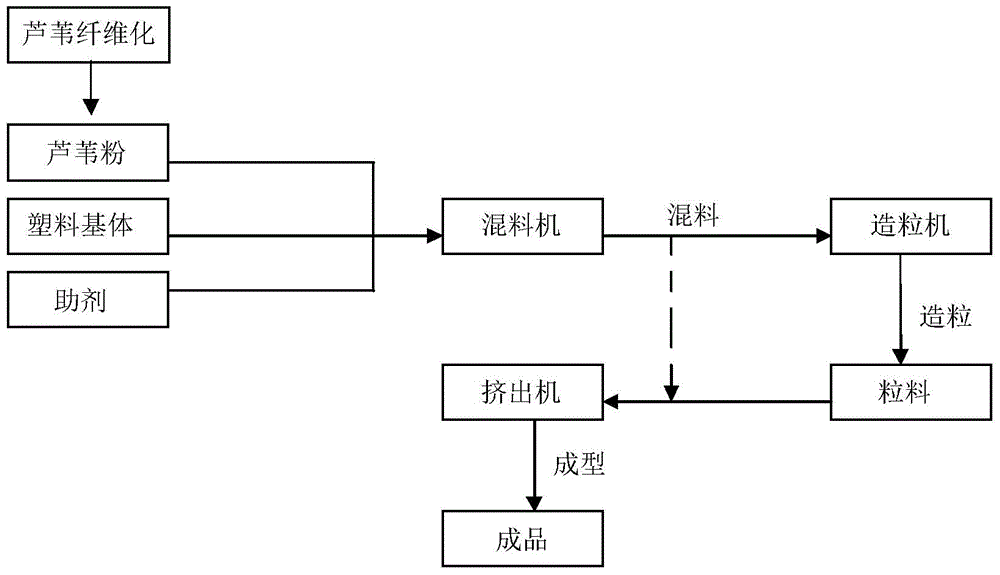

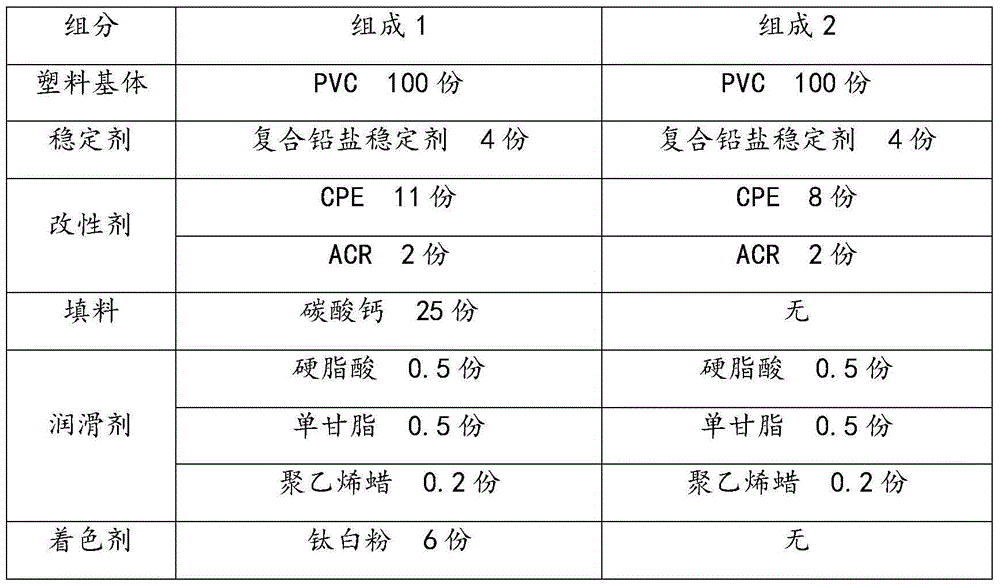

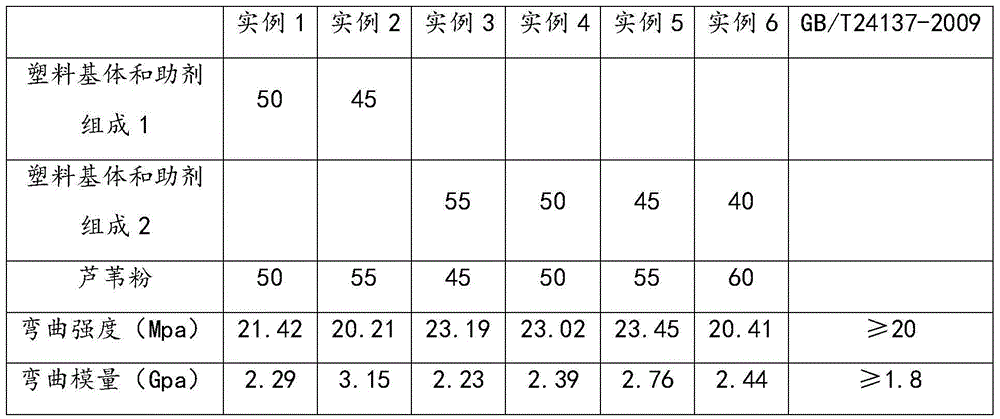

Industrialized production method of reed and wood-plastic composite material

The invention relates to an industrialized production method of a reed and wood-plastic composite material. The industrialized production method comprises the following steps: adopting the steam explosion method or the screw extrusion micro-carbonization method to make the reed raw material into fiberized reed powder; placing the fiberized reed powder, a plastic matrix and an additive into a mixer to be uniformly mixed; conducting extrusion molding after the materials are granulated in a granulator, or, directly conducting extrusion molding on the materials. The industrialized production method is simple in step and convenient to implement, can obtain the reed and wood-plastic composite with superior physical property, is suitable for handy, high-value and environment-friendly recycling utilization of water and wetland reed of lakes, river courses, reservoirs and the like, and is conducive to meeting the huge-amount requirement on the wood-plastic product market.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Eukaryotic no-reference transcriptome interaction analysis system and method based on computing cloud platform

InactiveCN109243532AMeet huge demandMeet needsData visualisationHybridisationConsequence analysisOriginal data

The invention discloses a eukaryotic no-reference transcriptome interaction analysis system and method based on a computing cloud platform. The system comprises a project management module which is used for viewing and managing the project information; a basic analysis task submitting module which is used for setting the basic parameter running task and integrating and encapsulating the result andthe raw data into the corresponding project files according to the preset format; and an interactive result analysis module which is for generating the analysis result according to the user request and visually displaying the result. According to the system and the method, a highly integrated data analysis platform is provided through the help of the cloud computing technology so as to lay a goodfoundation for basic analysis, advanced analysis and personalized analysis of the eukaryotic no-reference transcriptome project.

Owner:上海桑格信息技术有限公司

Planting method of purple perilla

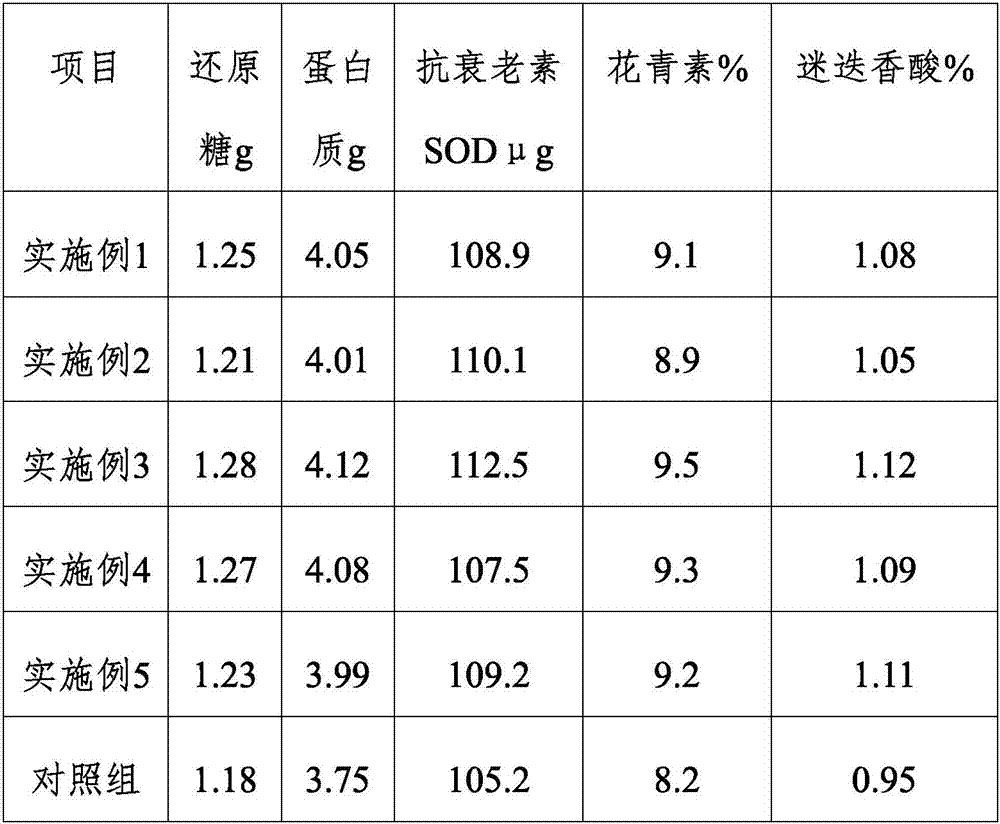

InactiveCN106888793AStrong insect resistanceIncrease productionBiocideMagnesium fertilisersReducing sugarPesticide

The invention belongs to the technical field of agricultural product planting and particularly relates to a planting method of purple perilla. The planting method includes the following steps of land preparation and sowing, fertilization, weeding, disease and pest prevention and control, field management and harvesting. The purple perilla planted through the planting method is high in disease and pest resistance, high in yield and high in pesticide effect, compared with the per mu yield of purple perilla planted through a traditional method, the yield can be increased by 18.3% to 22.0%, the content of the effective ingredients of reducing sugar, protein, the anti-aging element, anthocyanin and rosmarinic acid of the purple perilla is effectively increased compared with the traditional method while the per mu yield of the purple perilla is effectively increased through the planting method, the pesticide effect is improved, and great requirements of the current market on the purple perilla are met.

Owner:贵州侗乡生态农业科技发展有限公司

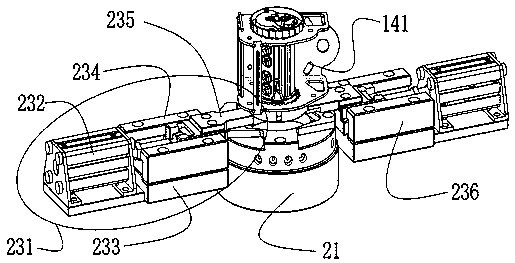

Device for automatically assembling seat belt retractor

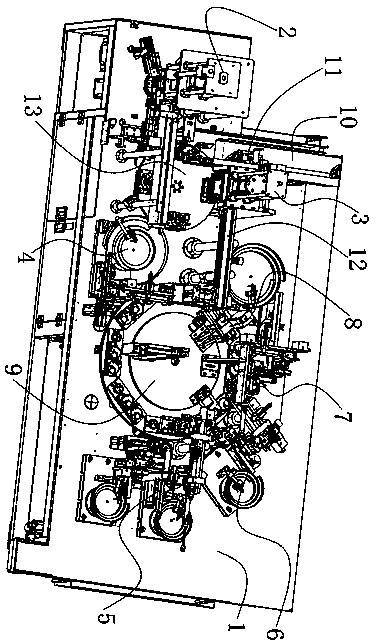

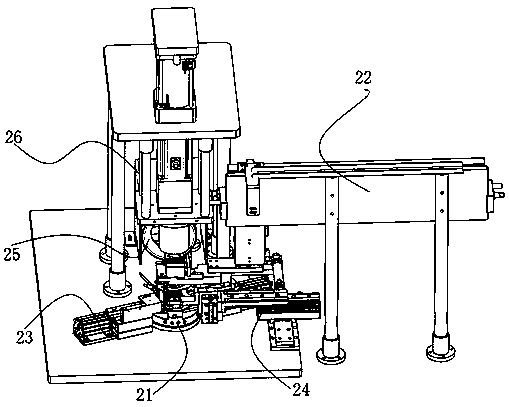

ActiveCN111185758ACompact structureReduce workflowAssembly machinesMetal working apparatusRatchetRobot hand

The invention relates to a device for automatically assembling a seat belt retractor. The device comprises a worktable; a first rotary disk device and a second rotary disk device that are arranged left and right are mounted at the upper part of the worktable; four placing stations are annularly arranged at the upper part of the first rotary disk device in an equally-spaced manner; a feeding manipulator, a ratchet assembling mechanism, a pressing mechanism and a transfer manipulator are sequentially mounted at the upper part of the worktable in the counterclockwise rotation direction o the first rotary disk device; a feeding conveying assembly is installed on the rear side of the feeding manipulator; eight assembling stations are annularly arranged at the upper part of the second rotary disk device in an equally-spaced manner; and an upper shell feeding mechanism, a mandrel main wheel feeding mechanism, a synchronous feeding mechanism, a first gear assembling mechanism, a second gear assembling mechanism, a third gear assembling mechanism and an end cover transfer press fitting mechanism are sequentially mounted at the upper part of the worktable in the rotation direction o the second rotary disk device; and the device has a compact structure, shortens the working process, fully automatically improves the assembling efficiency, reduces the manual participation, and improves theassembling accuracy and efficiency.

Owner:XUCHANG UNIV

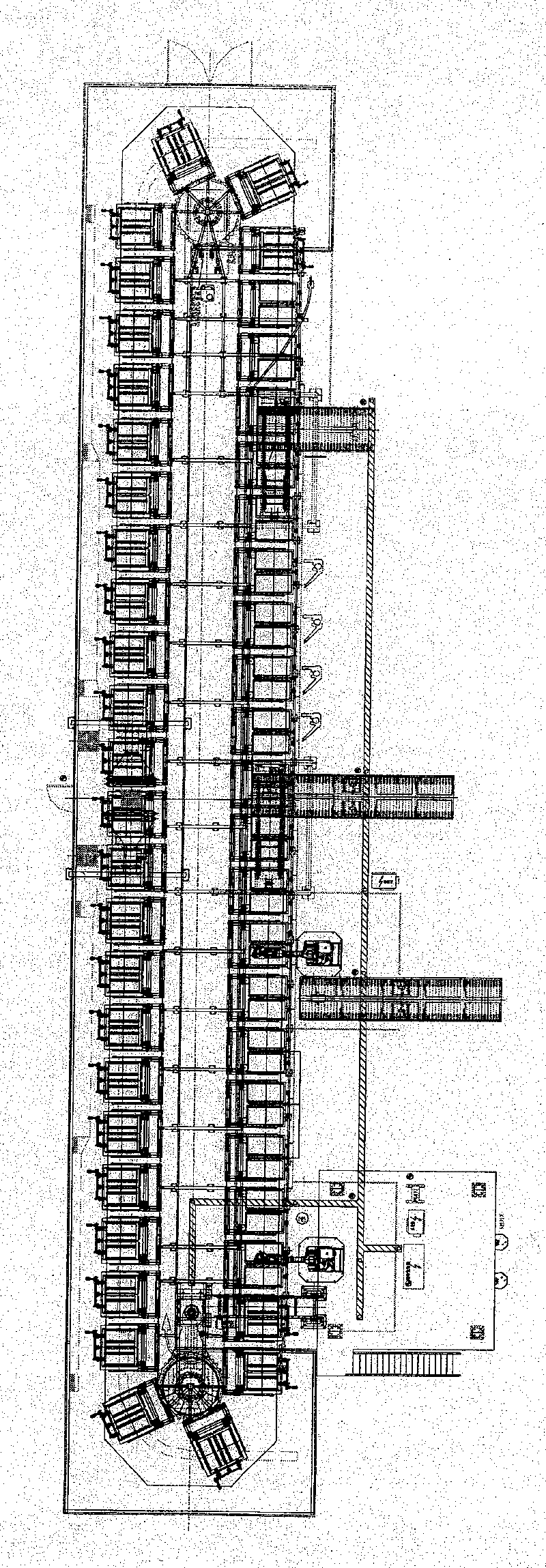

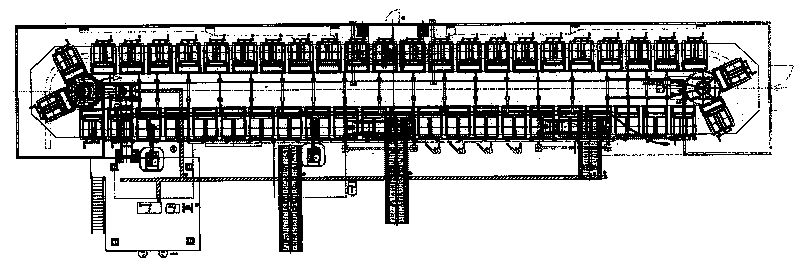

Continuous production process for polyurethane thermal insulation boards

InactiveCN101694115ASolve the problem of external wall insulationReduced external wall insulation problemsGripping headsHeat proofingProduction lineThermal insulation

The invention relates to a continuous production process for polyurethane thermal insulation boards, belonging to a new process of continuous production of polyurethane thermal insulation boards. The invention aims to provide a continuous production process for continuously producing polyurethane energy-saving boards and is characterized by comprising the process routes of laminating dies on the inner wall of a frame, preinstalling lower die cement-fibre boards, preinstalling robot upper die cement-fibre boards, casting preparation, robot casting, compounding dies, heating curing, die sinking, taking pieces, cleaning dies, carrying down and circulating. The invention has the advantages that firstly, the operating mode of the continuous product line of the polyurethane thermal insulation boards is continuous production so that the production efficiency is greatly improved, the demands of domestic construction energy-saving markets can be satisfied, and the construction energy-saving project of China are greatly promoted; secondly, the continuous production process has good energy-saving and environment-protection effect, thereby making a contribution to establishing a resource saving and environment-friendly society; and thirdly, the process has stable and reliable production, guaranteed quality, high production capacity, high technical content, high degree of automation, low labor intensity and controllable quality.

Owner:HUNAN JINGZHENG EQUIP MFG

Scutellaria viscidula chalcone synthetase albumen coded sequence

InactiveCN101240266AIncrease contentIncrease productionFungiEnzymesGenetic engineeringScutellaria baicalensis

A collecting hairs baikal skullcap root chalcone ketone synthetase albumen coding sequence belongs to genetic engineering field comprises encoding polypeptides nucleotide sequence possessing chalcone ketone synthetase albumen activity which the nucleotide sequence and the 54-752 bit nucleotide sequence in SEQ ID NO.3 has 70124564mology, or the nucleotide sequence can cross-fertilize with the 54-752 bit nucleotide sequence in SEQ ID NO.3 in condition of 45-55 DEG C. The invention has evident action for improving the content of flavonoid such as baikal skullcap root glycosides in collecting hairs baikal skullcap root plant material also the invention has prodigious applications worthiness.

Owner:SOUTHWEST UNIVERSITY

Flavanone 3-hydroxylase protein coded sequence of scutellaria viscidula bge

InactiveCN101544984AIncrease contentIncrease productionFungiOxidoreductasesNucleotideScutellaria viscidula

The invention discloses a flavanone 3-hydroxylase protein coded sequence of scutellaria viscidula bge, and belongs to the field of genetic engineering. A nucleotide sequence of polypeptide with flavanone 3-hydroxylase activity is coded, and consists of a nucleotide sequence from the 74th position to the 1,123th position of nucleotides in SEQ ID NO.3 or a degenerate sequence thereof; and the sequence codes the polypeptide with the nucleotide sequence shown in the SEQ ID NO.3. The flavanone 3-hydroxylase protein coded sequence has obvious effect of improving contents of flavonoid compounds such as baicalin and the like in scutellaria viscidula bge plants, and has great application value.

Owner:SOUTHWEST UNIVERSITY

Needle-leaved tree agaric cultivation method

ActiveCN105248147AMeet huge demandMeet needsCalcareous fertilisersBioloigcal waste fertilisersAgaricEconomic benefits

The invention relates to the edible and medical fungi cultivation technical field, and specifically relates to a needle-leaved tree agaric cultivation method comprising the following steps: 1, inoculating first grade mother strain of the needle-leaved tree agaric in a first medium to carry out first time hairy fungus, thus obtaining second grade stock seeds; 2, inoculating the second grade stock seeds in the second medium so as to carry out second time hairy fungus, and after a mycelium incubation period and a sporocarp incubation period, the needle-leaved tree agaric can be obtained. The needle-leaved tree agaric is a rare breed, the invention provides the efficient and doable artificial cultivation method, thus providing high economic benefits, and bringing a good project for farmer achieving prosperity.

Owner:SHANGZHI ZHENQI TRADITIONAL CHINESE MEDICINAL MATERIAL TECH

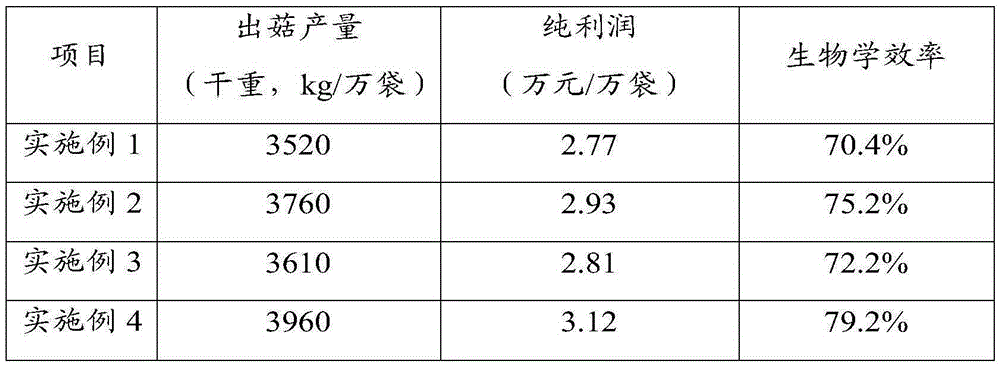

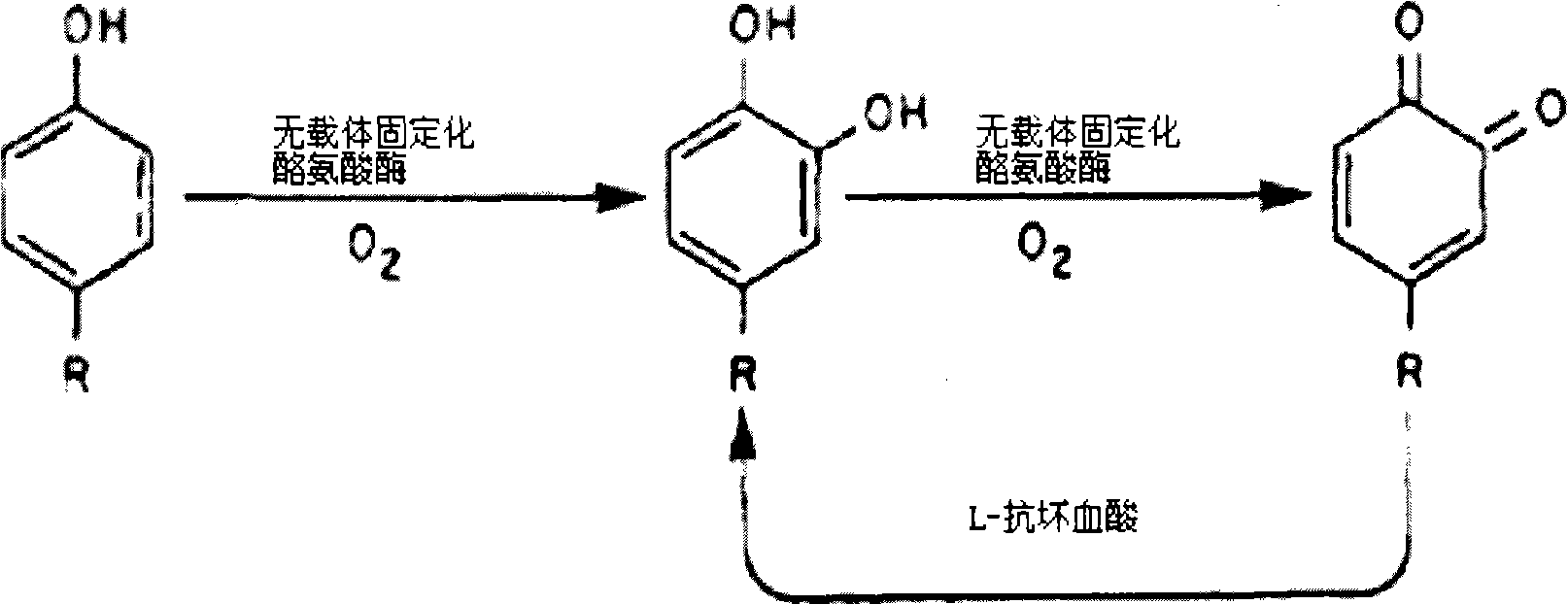

Method for synthesizing medicament L-dopa by enzyme catalysis

The invention belongs to the technical field of preparation of a medicament L-dopa. In order to solve the technical problem that the medicament L-dopa is difficultly synthesized by biological catalysis in the prior art, the invention provides a method for synthesizing a medicament L-dopa by enzyme catalysis. In the method, L-tyrosine is used as a raw material, and the L-dopa is generated by catalysis of carrier-free immobilized tyrosinase.

Owner:SHENZHEN UNIV

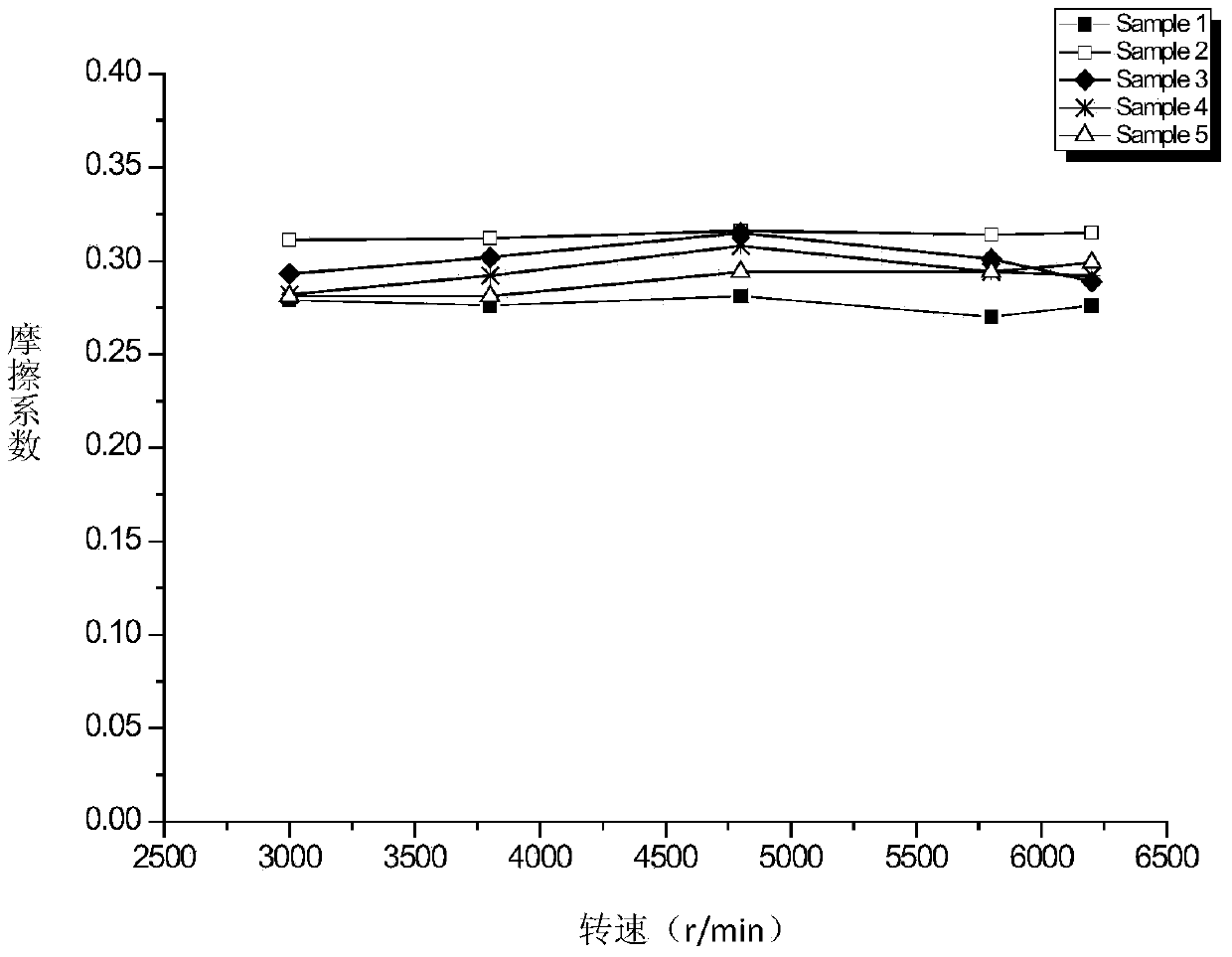

Continuous air pressure sintering method for copper-based composite material friction block

The invention relates to a continuous air pressure sintering method for a copper-based composite material friction block, and belongs to the field of train braking systems. The copper-based composite material friction block is composed of copper powder, ferrous powder, flake graphite, molybdenum disulfide, aluminum oxide and chromite. All components are mixed uniformly and formed by cold-pressing; and then blanks are sintered by using continuous sintering equipment. In the sintering process, air pressure sintering is employed; a gas pressure in a furnace chamber is 0.5-3 MPa; and the gas is formed by mixing hydrogen and nitrogen. The continuous air pressure sintering method overcomes fluctuation and difference of sample performance among batches caused by conventional intermittent sintering with a bell type furnace or a hot-pressing furnace, prevents energy consumption of repeatedly heating and cooling among the bathes in the intermittent sintering. A prepared material has density uniformity and structure continuity in all directions, and is beneficial to stabilize friction performance and absorb sound and reduce noise. The performance of a product obtained by the continuous air pressure sintering method is superior to that of a product obtained by the conventional sintering method. The continuous air pressure sintering method is low in production cost and high in production efficiency and can realize large-scale production easily.

Owner:UNIV OF SCI & TECH BEIJING

Sutellaria viscidula phenyl alanine ammonialyase protein coded sequence

InactiveCN101532026AIncrease contentIncrease productionFungiHydrolasesNucleotideNucleotide sequencing

The invention provides a sutellaria viscidula phenyl alanine ammonialyase protein coded sequence belonging to the genetic engineering field. Polypeptide nucleotide sequences having phenyl alanine ammonialyase activity are coded. The nucleotide sequences are composed of nucleotide sequences from positions 129 to 2261 in the SEQ ID NO.3 or simplified sequences. The sequences code polypeptide having amino acid sequences showed by SEQ ID NO.3. The invention obviously improves content of flavonoid compounds for instance scutelloside in sutellaria viscidula plants and has great application value.

Owner:SOUTHWEST UNIVERSITY

Adult yellow croaker feed and preparation method thereof

InactiveCN107212188APromote growthReduce growth loadFodderClimate change adaptationAnimal scienceAdditive ingredient

The invention belongs to the field of feed, and especially relates to adult yellow croaker feed and a preparation method thereof. The feed includes the following ingredients in parts by weight: 20-40 parts of bone meal, 12-18 parts of corn gluten meal, 12-18 parts of fish meal, 10-20 parts of earthworm powder, 15-25 parts of lecithin powder, 20-30 parts of strong flour, 8-12 parts of inositol, 3-8 parts of sodium alginate, 10-20 parts of dextrin, 10-20 parts of scallop powder, 15-25 parts of fish oil, 15-25 parts of sesame oil, 2-8 parts of lysine, 3-6 parts of aspartic acid, 15-25 parts of fermentation materials, 4-9 parts of zymophyte, 20-30 parts of compound traditional Chinese medicine and 3-8 parts of complex vitamins. Based on the development state of the digestive system and immune system of the adult yellow croaker and ingredient selection, the feed provided by the invention further improves full nutrient absorption of the adult yellow croaker, improves feed digestibility and improves the yield and quality of the adult yellow croaker through a reasonable combination of protein, fat and amino acids so as to meet the great demand on the yellow croaker in the market.

Owner:铜仁市万山区生态渔业养殖有限公司

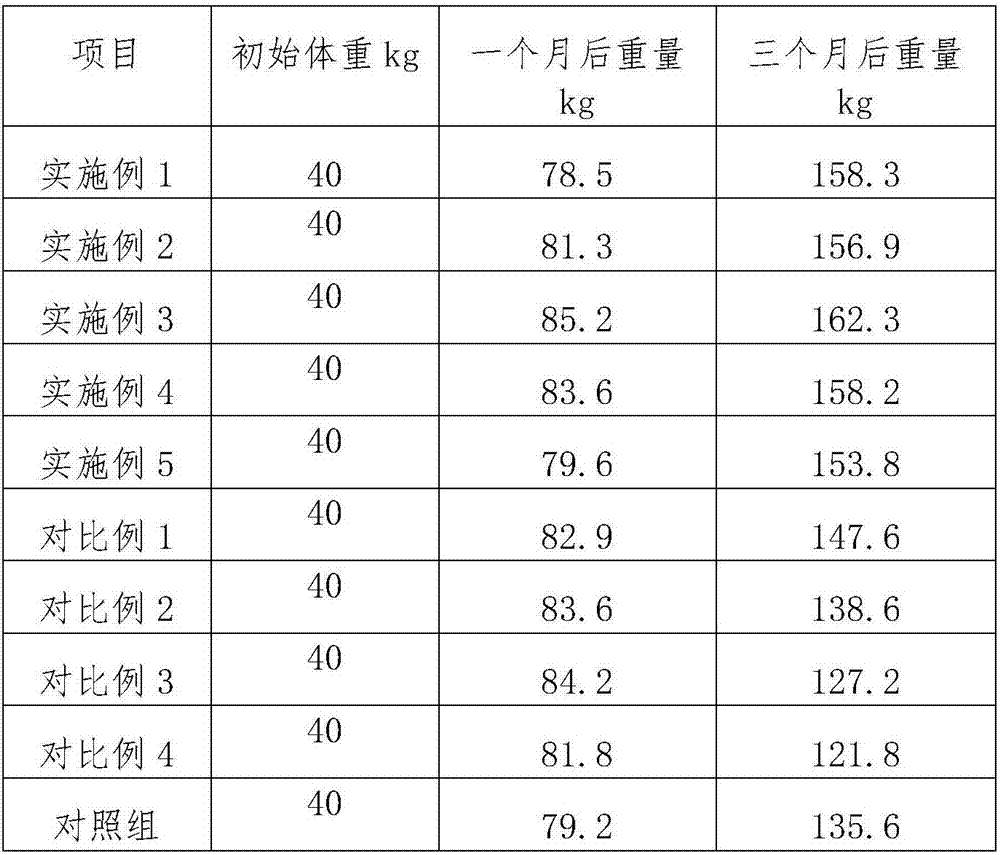

Special feed for fattening cattle and preparation method thereof

InactiveCN107156470AImprove digestibilityPromote growthFood processingAnimal feeding stuffOysterOligosaccharide

The present invention belongs to the field of feed and particularly discloses a special feed for fattening cattle. The special feed comprises the following raw materials: shrimp shell powder, bone meal, moringa oleifera leaves, beet pulp, sesame seed powder, distillers' grains, sweet potato vines, edible fungus residues, bagasse, palm meal, spirulina platensis, urea phosphate, edible salt, oligosaccharides, zeolite powder, gypsum, moutan barks, folium perillae, herba elsholtziae, rhizoma dioscoreae nipponicae, ajuga nipponensis, cortex lycii radicis, honeysuckle stems, poria cocos, rhizoma alismatis, pulsatilla chinensis roots, rhizoma atractylodis macrocephalae, radix morindae officinalis, striga asiatica, fiveleaf gynostemma herb, oysters, compound probiotics, fermentation micro-organisms, an enzyme agent and a phagostimulant. Aiming at development situations of digestion system and immune system of beef cattle, combining a screening of the raw materials, and combining proteins, fats and amino acids in a reasonable ratio, the feed further improves full absorption of nutrients by the beef cattle, improves digestibility, improves production and quality of the beef cattle, and meets huge demands of current markets for the beef cattle.

Owner:普定县展翼养殖专业合作社

Milk cow feed containing cow dung

InactiveCN106615730AEnsure nutritional needsImprove palatabilityFood processingAnimal feeding stuffAnimal ForagingMilk cow's

The invention relates to the technical field of feeds and particularly relates to a milk cow feed containing cow dung. The milk cow feed is prepared from the following raw materials in parts by weight: 40-50 parts of cow dung, 20-30 parts of forage grass, 15-20 parts of wheat bran, 25-30 parts of corns, 10-15 parts of pods, 18-25 parts of sorghum husk, 12-15 parts of hay, 6-12 parts of cabbage, 12-16 parts of beet, 7-13 parts of bone meal, 2.5-3.5 parts of urea phosphate, 1-2 parts of calcium phosphate, 2-3.5 parts of table salt, 8-12 parts of fish liver oil, 1.1-1.7 parts of sodium selenite, 1-2 parts of lactic acid bacteria, 1-3 parts of methionine, 1-2 parts of aspartic acid, 18-25 parts of Chinese herbal medicines and 8-15 parts of accessories. The milk cow feed has no hormone and residue, is rich in various nutrient substances required by the growth of dairy cattle, so that the milk yield can be increased, and the quality of milk can be improved; meanwhile, waste materials can be recycled, the environmental pollution caused by the cow dung is reduced, and the breeding cost is greatly lowered.

Owner:广西山水牛畜牧业有限责任公司

Fireproof insulation board of aerated concrete of B02-level light sand

The invention discloses a fireproof insulation board of aerated concrete of B02-level light sand. The constituents and weight percentages of the fireproof insulation board are as follow: 45-55% of quartz sand, 12-16% of lime, 24-37% of cement, 5% of gypsum, 0.25-0.35% of aluminite powder and 0.2-0.6% of composite admixture, wherein the composite admixture is admixture with composite stabilizing, toughening and waterproof functions, and the constituents and weight percentages are as follow: 25-30% of sodium abietate, 22-26% of chlorinated paraffin, 24-28% of petroleum ether and 20-25% of organo-siloxane. The fireproof insulation board has the advantages that the fireproof insulation board compensates the disadvantages and defects of the prior art, overcomes the production difficulties, and improves the casting stability when reducing dry density of the aerated concrete product of the sand, so as to conveniently transport and construct the product, and meet huge demands of the construction market and energy conservation and environmental protection requirements of people on building materials in cities.

Owner:天津滨海天筑永利建材有限公司

Special feed for sturgeons and preparation method thereof

InactiveCN107156540AImprove digestibilityPromote growthFood processingClimate change adaptationBiotechnologyAntioxidant

The present invention belongs to the field of feeds and particularly relates to a special feed for sturgeons and a preparation method thereof. The feed comprises the following raw materials: krill powder, shell powder, seaweed powder, bone meal, dextrin, puffed soybeans, peanut bran, casein, fish oil, flaxseed oil, D-glucose, lysine, isoleucine, tryptophan, pine needles, realgar, semen strychni, radix rehmanniae preparata, semen cuscutae, radix stephaniae tetrandrae, agrimonia pilosa, rhizoma anemarrhenae, aloe vera, cactus, polygonum cillinerve tuberous roots, a compound enzyme, a compound probiotic and an antioxidant. Aiming at development situations of digestion system and immune system of the sturgeons, combining a screening of the raw materials, and combining proteins, fats and amino acids in a reasonable ratio, the feed further improves full absorption of nutrients by the sturgeons, improves digestibility, improves production and quality of the sturgeons, and meets huge demands of current markets for the sturgeons.

Owner:普定县陇泉湾养殖有限公司

Comprehensive processing method for burdock root

InactiveCN100493375CIncrease added valueHigh activityFood preparationPlant ingredientsAlcoholEconomic benefits

The comprehensive burdock root processing method includes the first washing of fresh burdock root, homogenating and filtering; the subsequent drying the filtrate to prepare whole component extract; or filtering the filtrate for the second time, adding alcohol for alcohol precipitation, collecting the precipitate, hydrolyzing the precipitate, secondary alcohol precipitating, decolorizing and drying to obtain burdock oligose; acid soaking the filter residue, filtering to obtain the filtrate as soluble dietary fiber and the filter residue as insoluble dietary fiber. The said comprehensive burdock root processing method can obtain several kinds of product and high economic benefit.

Owner:肖兵

Method for planting dendrobium officinale

InactiveCN106416978ASeedling root system developedStrong stress resistanceAlkali orthophosphate fertiliserExcrement fertilisersAdditive ingredientDrug effect

The invention relates to the technical field of plant planting, in particular to a method for planting dendrobium officinale. The method comprises the following steps of seedling selecting, seedling hardening, transplanting and field management. Planted dendrobium officinale seedlings are developed in root system and high in stress resistance and adaptive capacity to environment, the situation that the high yield of the dendrobium officinale is pursued before, excess fertilization and pesticide application are carried out, and consequently soil is damaged is avoided. By means of the method for planting the dendrobium officinale, after the dendrobium officinale is picked for the first time after being planted for 18 months, the acre yield is 300 jin or above, the yield is greatly increased, the effective ingredients of the dendrobium officinale planted through the method are close to the content of wild dendrobium officinale to the maximum extent, the drug effect of the dendrobium officinale is improved while the yield is guaranteed, the current great need of the market is met, and the economic value and medicinal value of the dendrobium officinale are achieved to the maximum extent.

Owner:紫云自治县瑞生中药材种植农民专业合作社

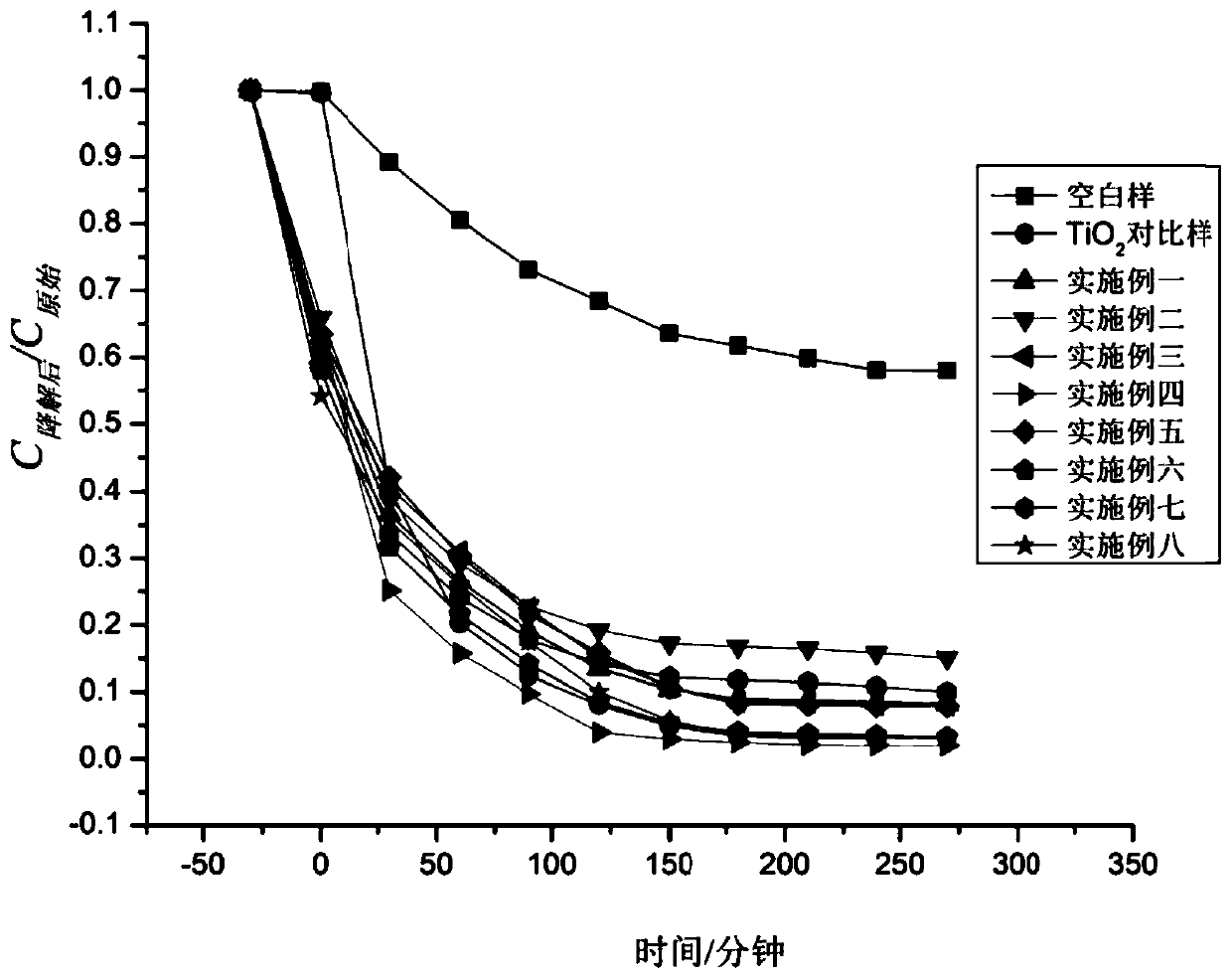

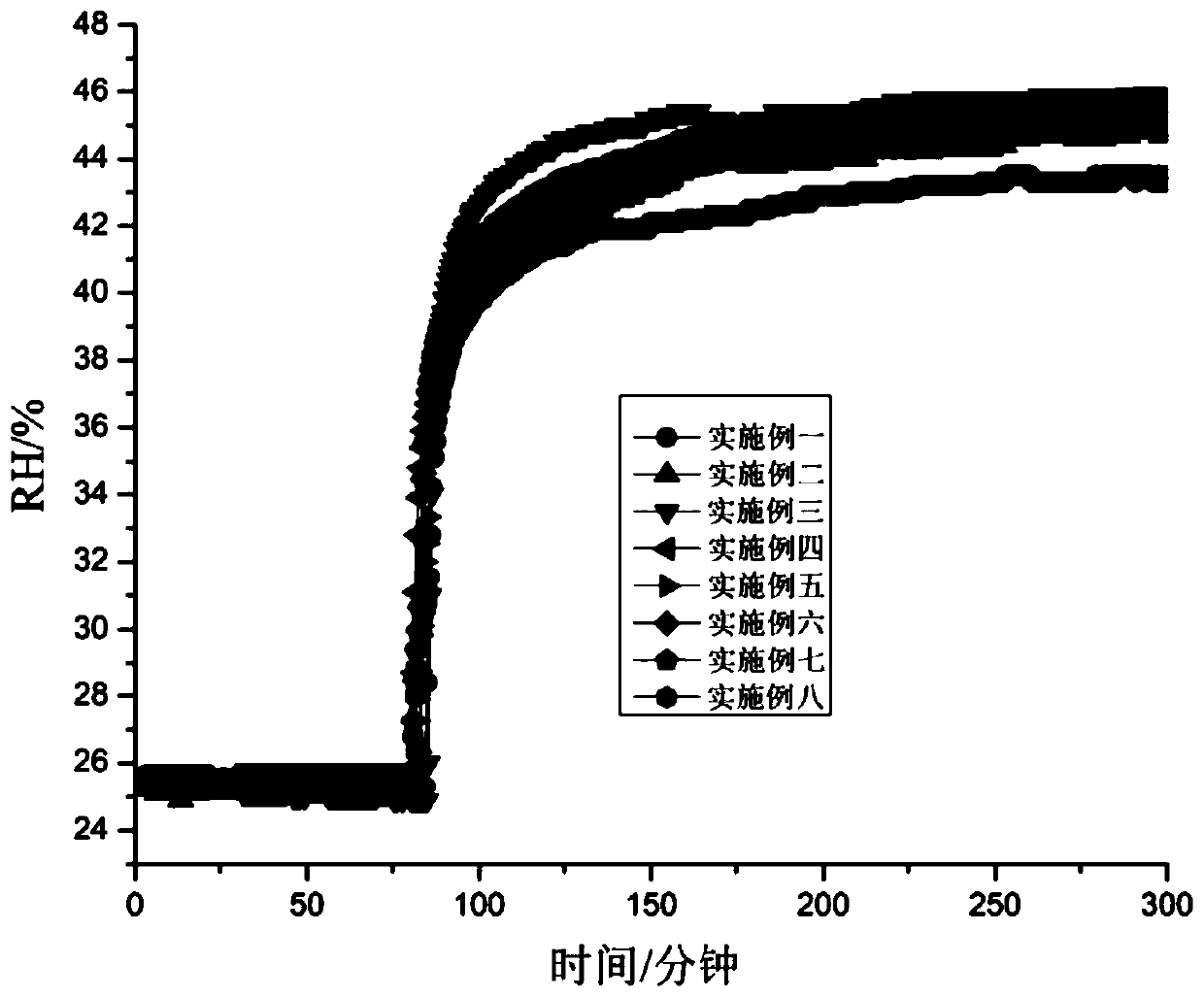

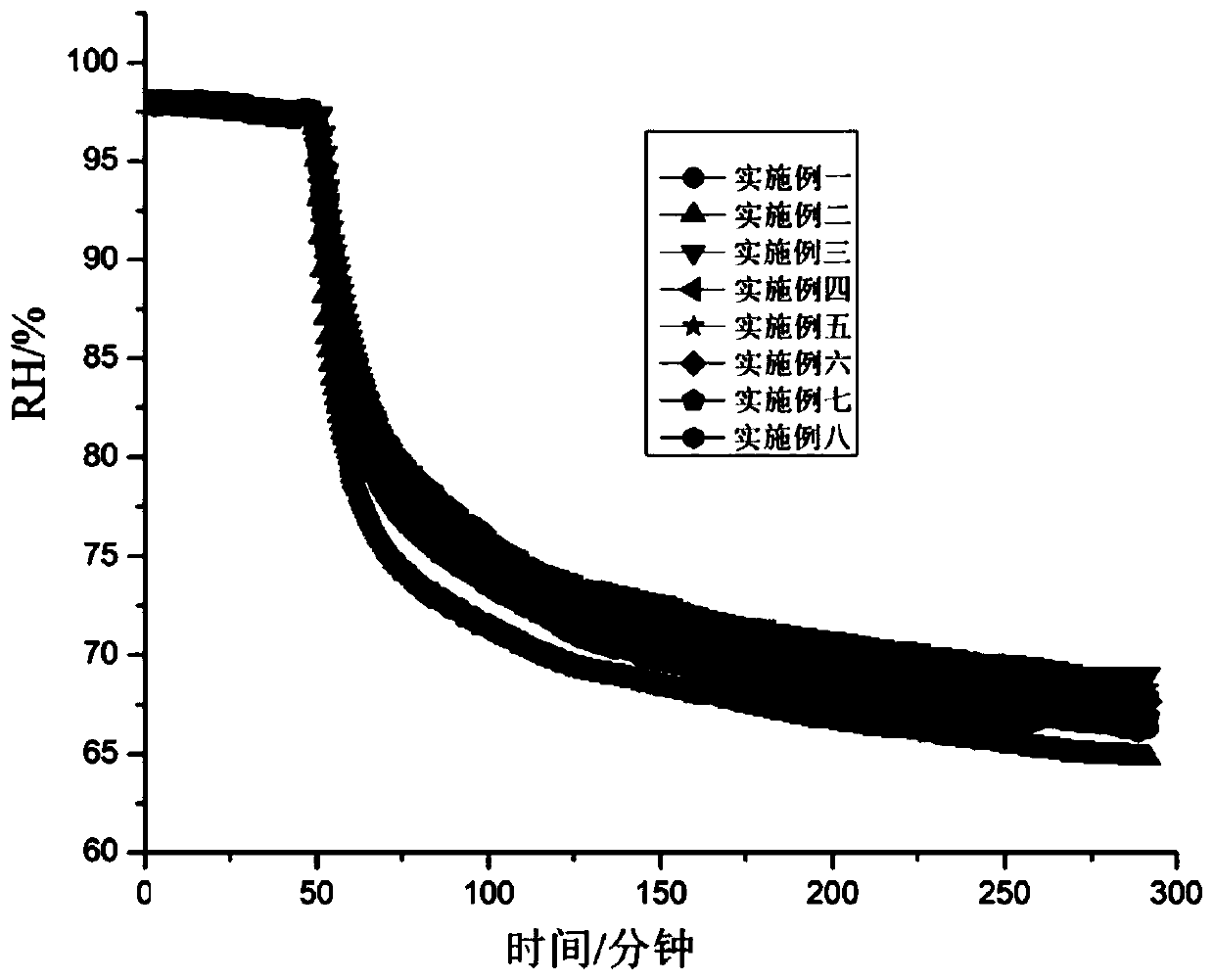

Geopolymer based on printing and dyeing sludge and heat-preservation sound-insulation humidity-adjusting plate

ActiveCN110451865APromote resource utilizationThe reaction process is compactSludge treatmentWater contaminantsSource materialSludge

The invention belongs to the technical field of solid waste treatment, particularly relates to a geopolymer based on printing and dyeing sludge and a heat-preservation sound-insulation humidity-adjusting plate, and further discloses a preparation method of the geopolymer and the plate. According to the geopolymer based on the printing and dyeing sludge, modified printing and dyeing sludge obtainedafter photocatalytic degradation is directly matched with fly ash, a silicon source material is added for adjusting a system to a proper silicon-aluminum ratio, organic matter is added, and then thelight geopolymer is obtained. The heat-preservation sound-insulation humidity-adjusting plate is prepared with the geopolymer serving as the raw material through a conventional method. The plate has relatively good noise-reducing, heat-insulating and humidity-adjusting performance, and can be widely applied to the field of functional building decoration.

Owner:ANHUI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com