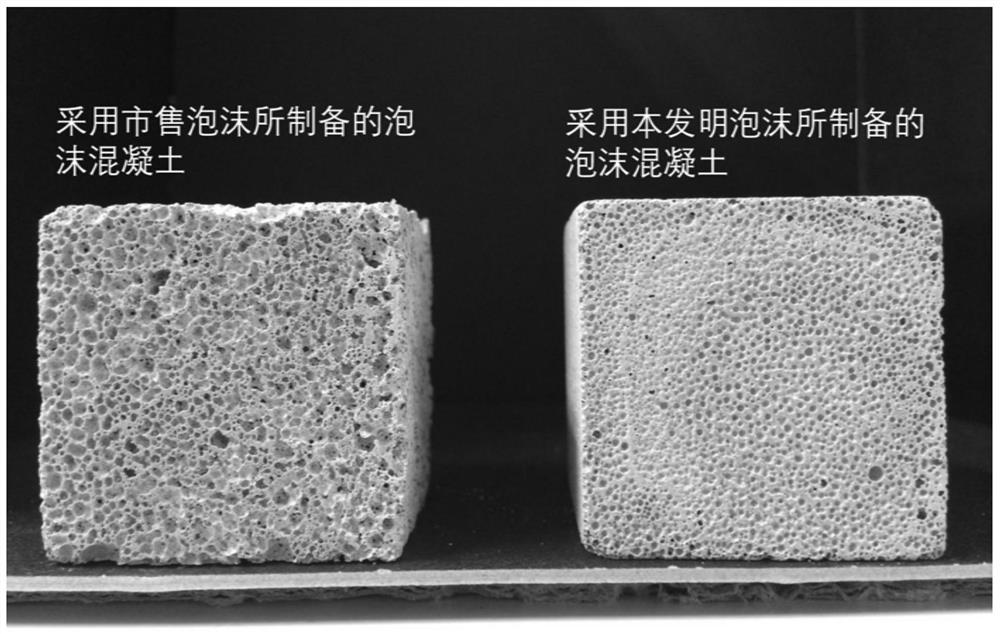

A kind of lightweight sound insulation material and preparation method thereof

A sound insulation material and lightweight technology, which is applied in the field of building materials to achieve the effect of resource regeneration and circulation, good sound insulation effect and consumption saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

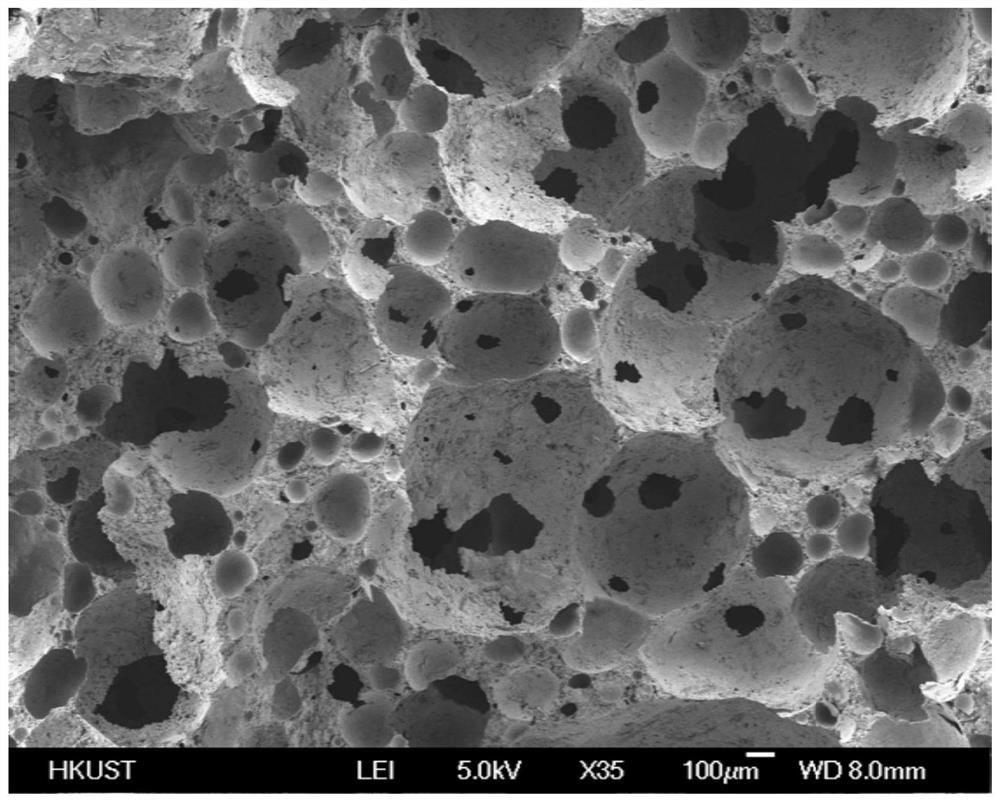

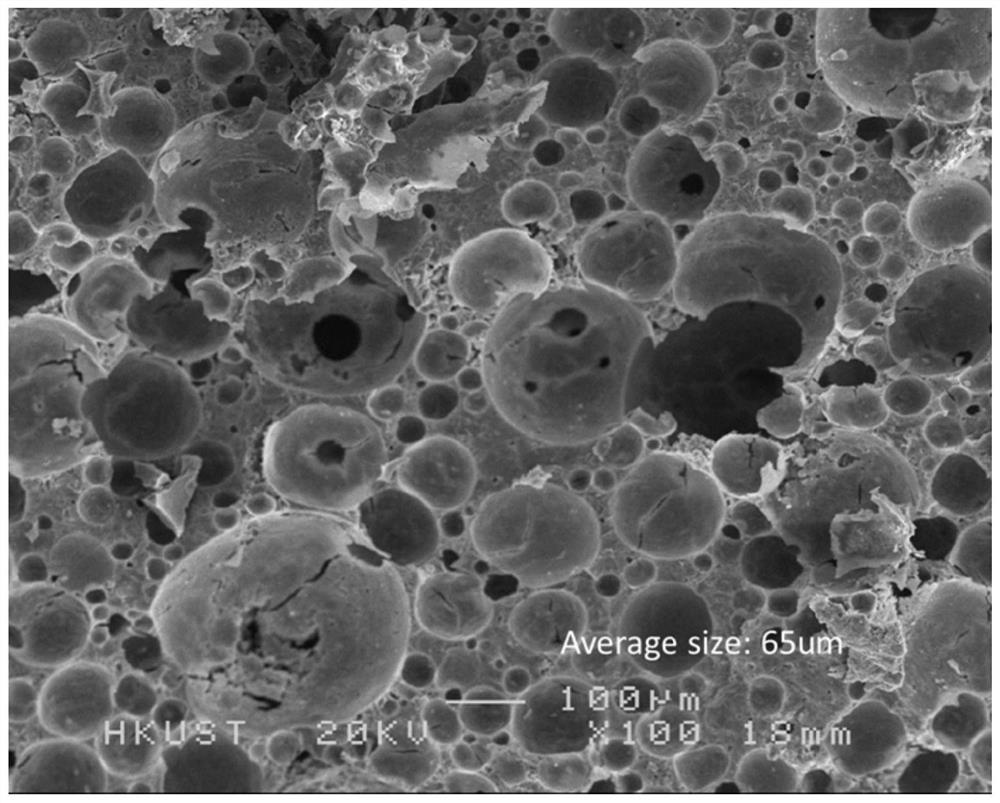

[0058] In this example, the foamed concrete dry material components for the preparation of lightweight sound insulation materials include the following components by mass: 200 parts of cement, 60 parts of dried sludge from water treatment plants, 25 parts of silica fume, 50 parts of fly ash, and 70 parts of gypsum powder 5 parts, 5 parts of slag, 5 parts of shell powder, 2 parts of water reducer, 0.05 part of foaming agent.

[0059] The blowing agent of this example is made up of the following components by mass: 3 parts of polyacrylamide, 5 parts of polyethyleneimine, 12 parts of polyvinylpyrrolidone, 45 parts of hydroxypropyl methylcellulose, 3 parts of triethanolamine, 6 parts Part surface hydrophilic modified nano-attapulgite powder, 26 parts of sodium lauryl sulfate.

[0060] Among them, the cement used is ordinary P·O 32.5 grade cement; the average particle size of silica fume is 0.1 μm ~ 0.3 μm; the fly ash is Class II F fly ash; the average particle size of gypsum powd...

Embodiment 2

[0068] The foaming agent used in this example is composed of the following components by mass: 4 parts of polyacrylamide, 12 parts of polyethyleneimine, 18 parts of polyvinylpyrrolidone, 40 parts of hydroxypropyl methylcellulose, 4 parts of triethanolamine, 5 parts of surface hydrophilic modified nano-kaolin powder, 17 parts of sodium dodecylbenzenesulfonate. The composition and preparation method of the remaining components are the same as in Example 1.

Embodiment 3

[0070] The foaming agent used in this example is composed of the following components by mass: 3 parts of polyacrylamide, 10 parts of polyethyleneimine, 15 parts of polyvinylpyrrolidone, 45 parts of hydroxypropyl methylcellulose, 2 parts of triethanolamine, 6 parts of surface hydrophilic modified nano-montmorillonite powder, 19 parts of AEO-9. The composition and preparation method of the remaining components are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com