Split combination type slag dam for tundish as well as preparation and use method of slag dam

A slag retaining wall, combined technology, applied in the direction of manufacturing tools, casting equipment, metal processing equipment, etc., can solve the problems of stress cracking, difficult to match high temperature thermal expansion coefficients, affecting life, etc., to achieve convenient preparation and use, low cost, Create convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

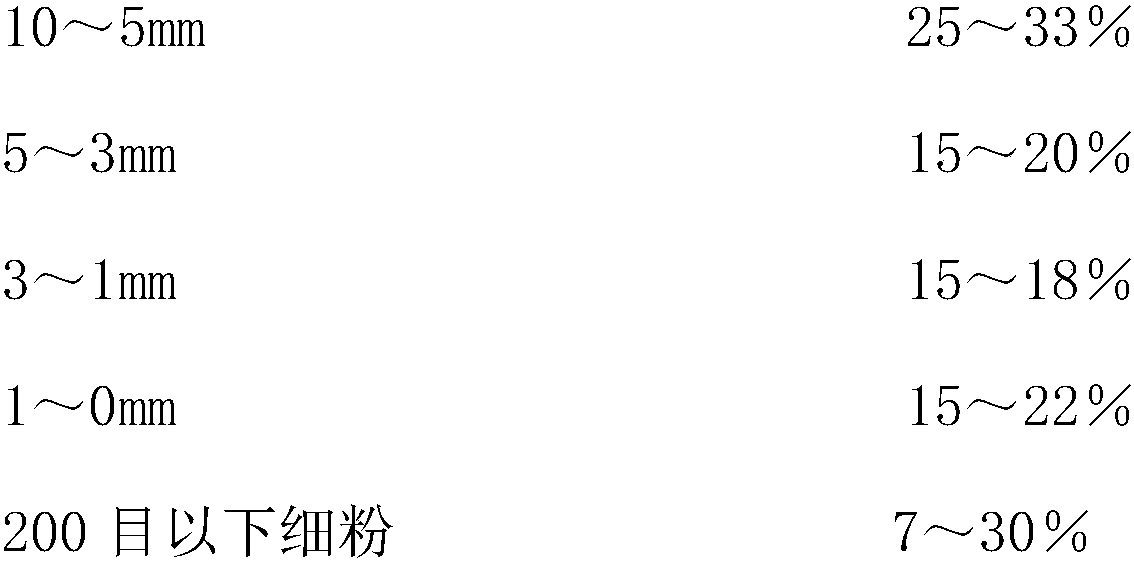

Embodiment 1

[0034] The main components of magnesium-aluminum-silicon on the upper slag line of the slag retaining wall for the split combined type tundish described in this embodiment are: MgO 50.0%, Al 2 o 3 36.5%, SiO 2 13.5%; specific raw material composition weight percentages are: mid-range sintered magnesia 31%, 96 fused magnesia 22%, bauxite clinker 43%, SiO 2 4% of superfine powder, and the percentage by weight of additional auxiliary materials is: 0.15% of sodium hexametaphosphate, 1.5% of heat-resistant stainless steel fiber, and 0.12% of organic explosion-proof fiber. The main components of magnesium silicon in the lower non-slag line are: MgO 85.5%, SiO 2 14.5%; the specific raw material composition weight percentage is: 95% fused leather sand, 6% fused waste quartz, SiO 2 4% of superfine powder, and the percentage by weight of additional auxiliary materials is: 0.15% of sodium hexametaphosphate, 1.5% of heat-resistant stainless steel fiber, and 0.12% of organic explosio...

Embodiment 2

[0040] The main components of magnesium-aluminum-silicon on the upper slag line of the split combined slag retaining wall described in this embodiment are: MgO43.5%, Al 2 o 3 42.5%, SiO 2 14%; specific raw material composition weight percentages are: mid-range sintered magnesia 28%, 96 fused magnesia 18%, bauxite clinker 50.0%, SiO 24% of superfine powder, and the percentage by weight of additional auxiliary materials is: 0.15% of sodium hexametaphosphate, 1.5% of heat-resistant stainless steel fiber, and 0.12% of organic explosion-proof fiber. The main components of magnesium silicon in the lower non-slag line are: MgO87.0%, SiO 2 13%; the specific raw material composition weight percentage is: mid-grade sintered magnesia 70%, 95 fused leather sand 22%, fused waste quartz 4%, SiO 2 4% of superfine powder, and the percentage by weight of additional auxiliary materials is: 0.15% of sodium hexametaphosphate, 1.5% of heat-resistant stainless steel fiber, and 0.12% of organi...

Embodiment 3

[0046] The main components of magnesium-aluminum-silicon on the upper slag line of the split combined slag retaining wall described in this embodiment are: MgO40.0%, Al 2 o 3 46.0%, SiO 2 14%; specific raw material composition weight percentages are: mid-grade sintered magnesia 23%, 96 fused magnesia 18%, bauxite clinker 50.0%, fused aluminum-magnesium spinel 5%, SiO 2 4% of superfine powder, and the percentage by weight of additional auxiliary materials is: 0.15% of sodium hexametaphosphate, 1.5% of heat-resistant stainless steel fiber, and 0.12% of organic explosion-proof fiber. The main components of magnesium silicon in the lower non-slag line are: MgO 87.5%, SiO 2 12.5%; the specific raw material composition weight percentage is: 95 fused leather sand 70%, 96 fused magnesia 22%, fused waste quartz 4%, SiO 2 4% of superfine powder, and the percentage by weight of additional auxiliary materials is: 0.15% of sodium hexametaphosphate, 1.5% of heat-resistant stainless ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com