Synthesis method of p-chloromethyl styrene

A technology of chloromethylstyrene and a synthesis method, which is applied in the fields of dehydrohalogenation preparation, organic chemistry, etc., can solve the problems of high temperature and high pressure, high energy consumption, and high equipment requirements for the reaction, and achieves low pollution, low energy consumption, and reduced energy consumption. side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

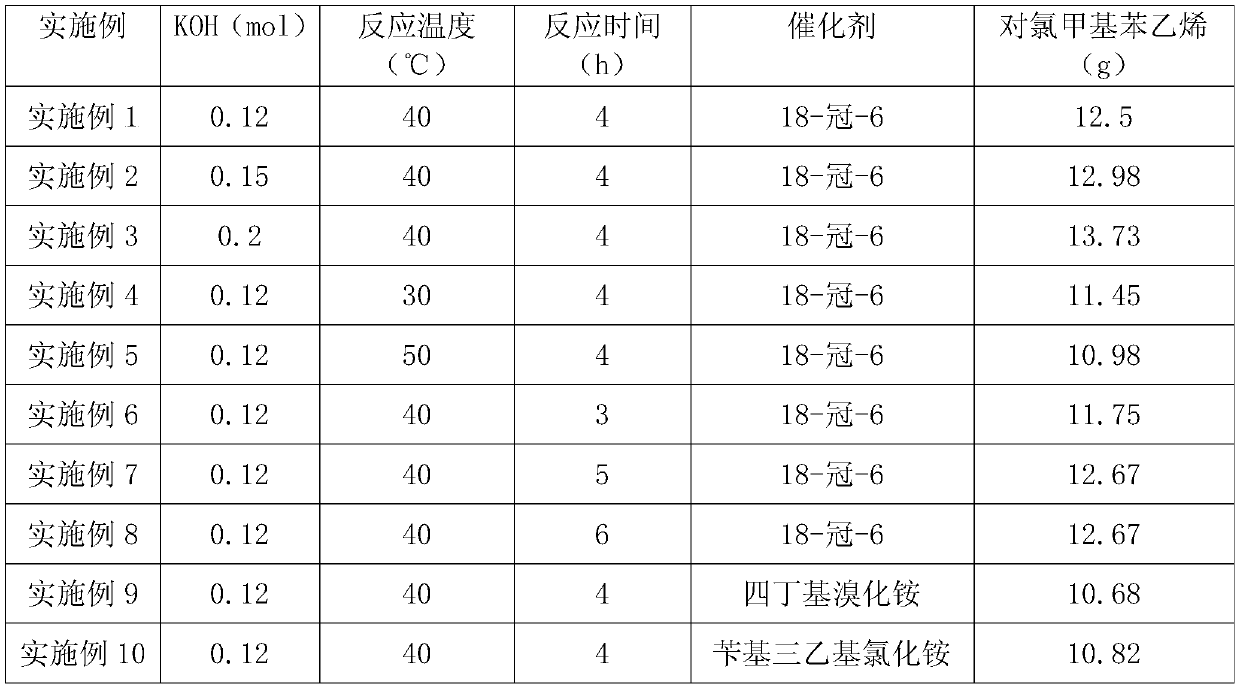

Embodiment 1

[0022] Add 23.4g of p-chloromethyl-α-bromoethylbenzene and 92g of toluene into a 500ml four-neck flask, stir to dissolve and clarify, add 6.72g of potassium hydroxide, 2g of 18-crown-6, and react at 40°C for 4 hours. Cool after the reaction, add 100g of water, stir to dissolve, and let stand to separate layers. The upper layer solution was extracted and distilled to obtain 12.5 g of p-chloromethyl styrene with a yield of 81.9%.

Embodiment 2

[0024] Add 23.4g of p-chloromethyl-α-bromoethylbenzene and 92g of toluene into a 500ml four-neck flask, stir to dissolve and clarify, then add 8.4g of potassium hydroxide and 2g of 18-crown-6, and react at 40°C for 4 hours. Cool after the reaction, add 100g of water, stir to dissolve, and let stand to separate layers. The upper layer solution was extracted and distilled to obtain 12.98 g of p-chloromethyl styrene with a yield of 85%.

Embodiment 3

[0026] Add 23.4g p-chloromethyl-α-bromoethylbenzene and 92g toluene into a 500ml four-neck flask, stir to dissolve and clarify, add 11.2g potassium hydroxide, 2g18-crown-6, and react at 40°C for 4 hours. Cool after the reaction, add 100g of water, stir to dissolve, and let stand to separate layers. The upper layer solution was extracted and distilled to obtain 14.5 g of p-chloromethyl styrene with a yield of 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com