Weather-resistant corrosion-resistant plastic plate

A plastic sheet and corrosion-resistant technology, applied in the field of building materials, can solve the problems of insufficient corrosion resistance, cracking of material products, and great decrease in toughness, and achieve excellent resistance characteristics, increase strength, and improve the effect of crystallization speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

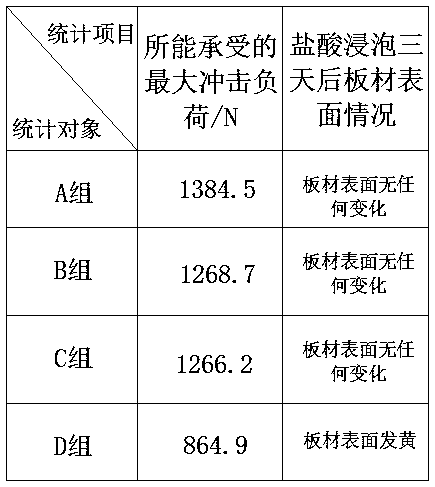

Examples

Embodiment 1

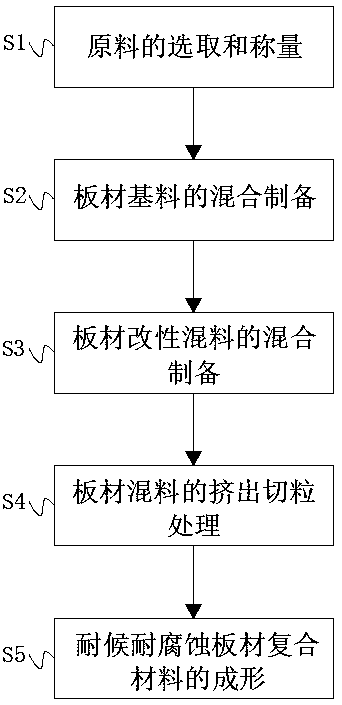

[0031] S1, selection and weighing of raw materials: First, 11 parts of polyolefin elastic toughening body, 6 parts of pentaerythritol stearic acid, 19 parts of EPDM toughened rubber, 6 parts of EPDM toughened rubber, Parts of hyperbranched lubricant, 20 parts of PA6 nylon, 43 parts of PA66 nylon, 6 parts of silicone powder, 7 parts of flame retardant, 6 parts of antioxidant, 6 parts of amino silicone oil, 7 parts of glass fiber and 5 parts of nucleating agent , and pour the measured components into storage tanks for centralized storage, and reserve them for later use. The flame retardant is made of phosphorus nitrogen-based environmentally friendly flame retardants, and the antioxidants are thiodipropionate diester and didodecyl alcohol Compositions of esters, trioctyl esters and tridecyl esters;

[0032] S2. Preparation of plate base material: PA6 nylon, polyolefin elastic toughener, PA66 nylon, pentaerythritol stearic acid, EPDM rubber, silicone powder, superbranch Put the ...

Embodiment 2

[0037] S1, selection and weighing of raw materials: First, take 8 parts of polyolefin elastic toughening body, 5 parts of pentaerythritol stearic acid, 10 parts of EPDM toughened rubber, 4 parts Parts of hyperbranched lubricant, 15 parts of PA6 nylon, 35 parts of PA66 nylon, 5 parts of silicone powder, 5 parts of flame retardant, 4 parts of antioxidant, 4 parts of amino silicone oil, 5 parts of glass fiber and 3 parts of nucleating agent , and pour the measured components into storage tanks for centralized storage, for future use. The flame retardant is a phosphorus nitrogen-based environmentally friendly flame retardant, and the antioxidant is thiodipropionate diester;

[0038] S2. Preparation of plate base material: PA6 nylon, polyolefin elastic toughener, PA66 nylon, pentaerythritol stearic acid, EPDM rubber, silicone powder, superbranch Put the chemical lubricant and glass fiber into the mixer in turn, and fully mix them at a speed of 500r / min and a temperature of 25°C for...

Embodiment 3

[0043] S1, selection and weighing of raw materials: First, 15 parts of polyolefin elastic toughening body, 8 parts of pentaerythritol stearic acid, 26 parts of EPDM toughened rubber, 8 parts of EPDM toughened rubber, Parts of hyperbranched lubricant, 25 parts of PA6 nylon, 52 parts of PA66 nylon, 8 parts of silicone powder, 10 parts of flame retardant, 8 parts of antioxidant, 10 parts of amino silicone oil, 10 parts of glass fiber and 7 parts of nucleating agent , and pour the measured components into storage tanks for centralized storage and reserve. The flame retardant is a phosphorus nitrogen-based environmentally friendly flame retardant, and the antioxidant is tridecyl ester;

[0044] S2. Preparation of plate base material: PA6 nylon, polyolefin elastic toughener, PA66 nylon, pentaerythritol stearic acid, EPDM rubber, silicone powder, superbranch Put the chemical lubricant and glass fiber into the mixer in turn, and fully mix them at a speed of 600r / min and a temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com