Method for improving point-like cavitation erosion resistance of hydraulic turbine runner by rare earth treatment

A water turbine and rare earth technology, which is applied in the field of steel materials and its products, can solve the problems of adverse effects on the safe service of water turbine runner parts, harsh service conditions, etc., and achieve good process feasibility, low cost, and improved cavitation resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

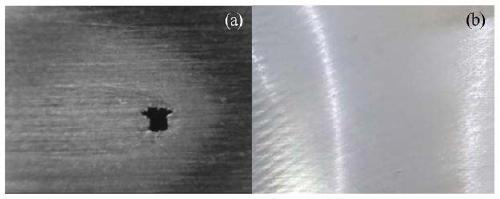

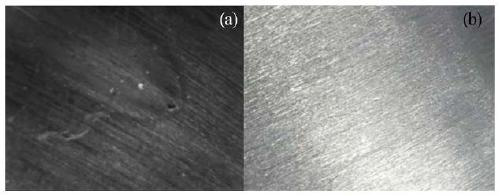

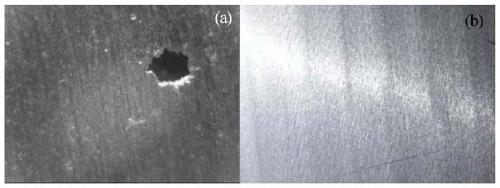

Image

Examples

Embodiment 1

[0045] In this implementation, ZG04Cr13Ni4Mo steel is commonly used as the upper crown, lower ring and blades of large water turbine runners.

[0046] The specific implementation process is as follows:

[0047] The traditional process is to use the LF furnace for smelting, and then use the VOD furnace for refining treatment. When the oxygen content and sulfur content of the molten steel are lower than 40ppm and 80ppm respectively, it is poured into the sand mold through the protective pouring method, and the molten steel is cooled and solidified to form a casting. , The castings are machined after normalizing + tempering treatment to reach the delivery state.

[0048] In the embodiment of the present invention, in the middle and late stages of the VOD treatment of molten steel, when the oxygen content is 20ppm and the sulfur content is 50ppm, the mixed rare earth lanthanum cerium is added to the molten steel according to the content of 100g per ton of steel by means of pressin...

Embodiment 2

[0051] In this implementation, ZG04Cr13Ni5Mo steel is commonly used as the upper crown, lower ring and blades of large water turbine runners.

[0052] The specific implementation process is as follows:

[0053] The traditional process is to use the LF furnace for smelting, and then use the AOD furnace for refining treatment. When the oxygen content and sulfur content of the molten steel are lower than 40ppm and 80ppm respectively, it is poured into the ingot mold through the protective pouring method, and the molten steel is cooled and solidified to form Electrode blanks, and then electroslag casting to manufacture blades, the castings are machined after normalizing + tempering to reach the delivery state.

[0054] In the embodiment of the present invention, in the middle and later stages of the AOD treatment of molten steel, when the oxygen content is 30ppm and the sulfur content is 72ppm, lanthanum metal is added to the molten steel by pressing in according to the content of...

Embodiment 3

[0057] This implementation is the 304 austenitic stainless steel used in the upper crown, lower ring and blades of the large water turbine runner.

[0058] The specific implementation process is as follows:

[0059] The traditional process is to use the LF furnace for smelting, and then use the AOD furnace for refining treatment. When the oxygen content and sulfur content of the molten steel are lower than 40ppm and 80ppm respectively, it is poured into the ingot mold through the protective pouring method, and the molten steel is cooled and solidified to form The electrode blank is then electroslag casted to produce the blade blank, and then heated to about 1000 ° C, and molded with a mold, and then the forging is machined after solution treatment to reach the delivery state.

[0060] In the embodiment of the present invention, in the middle and later stages of the AOD treatment of molten steel, when the oxygen content is 35ppm and the sulfur content is 75ppm, cerium metal is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com