Method for preparing film on contact lens by using plasma-assisted chemical vapor deposition method

A chemical vapor deposition, contact lens technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problem that the wearer cannot wear contact lenses, affecting the wearer's visual comfort and the surface of the lens. Wetting, shortened contact lens life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to achieve the above-mentioned purpose and effect, the technical means and the structure thereof adopted in the present invention are hereby illustrated in detail with respect to the preferred embodiments of the present invention. Its features and functions are as follows, so as to fully understand.

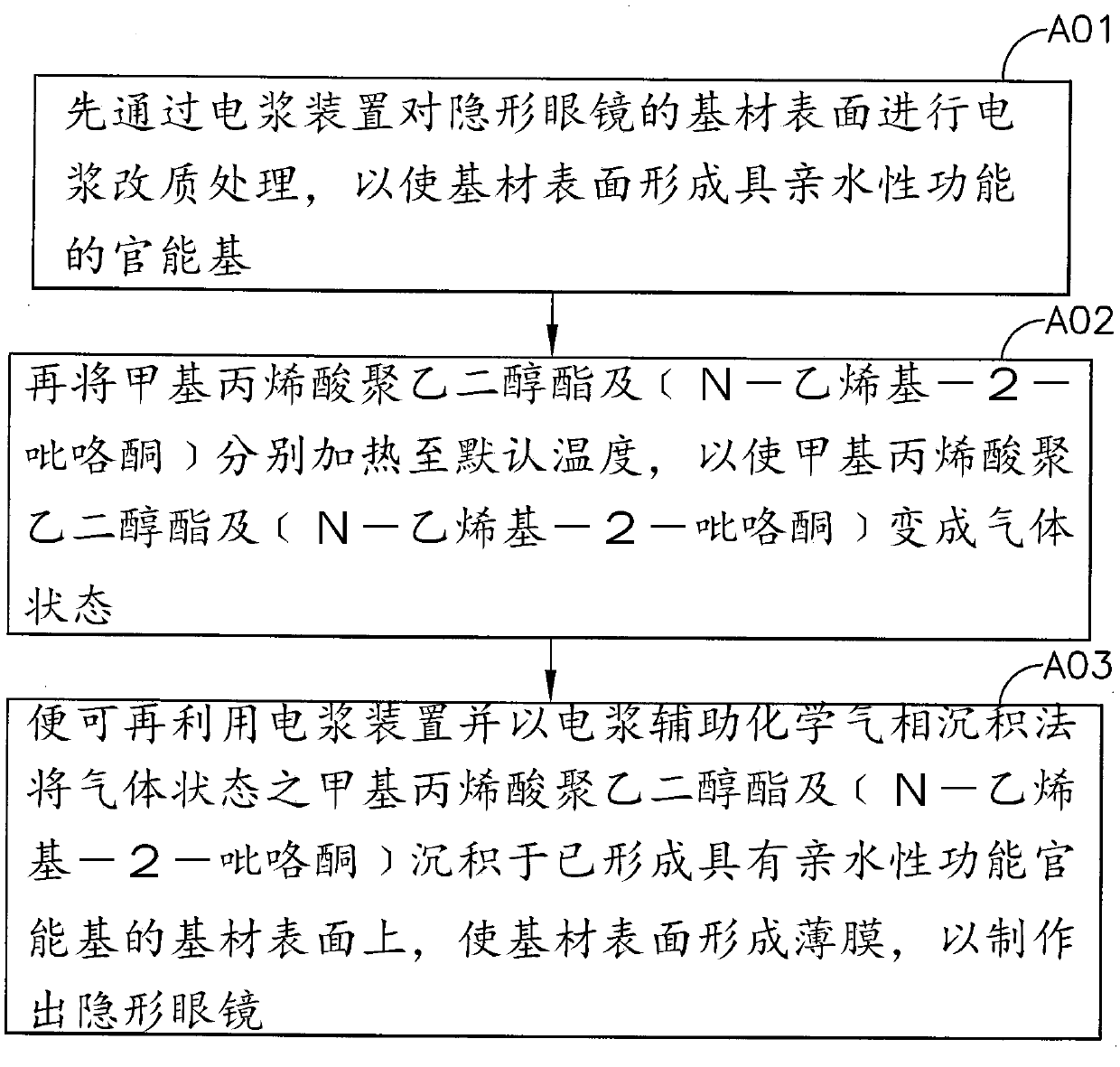

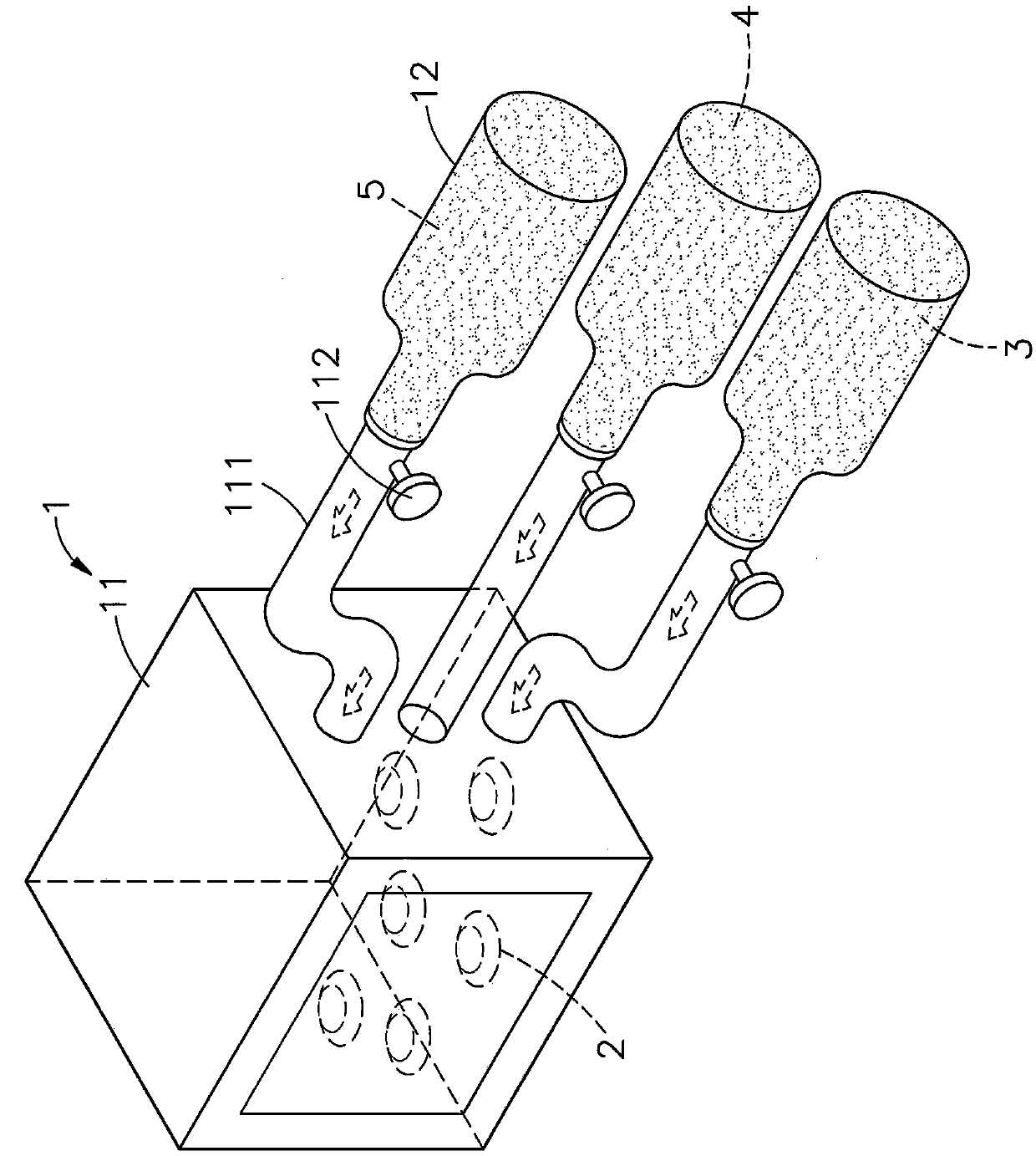

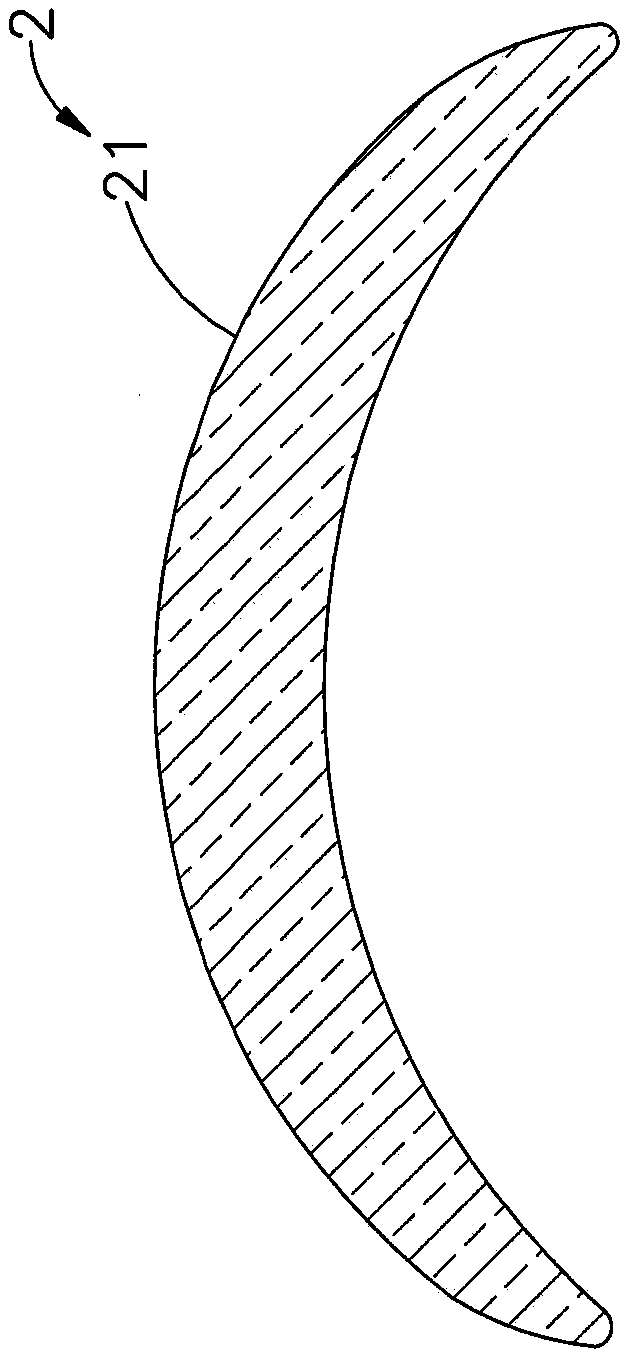

[0041] see Figure 1-4 Shown is a flow chart of the present invention, a schematic view of the use of the plasma device, a side view sectional view of the base material of the contact lens before the film is formed, and a side view sectional view of the base material of the contact lens after the film is formed. It can be clearly seen from the figure Find out, the present invention utilizes plasma-assisted chemical vapor deposition to prepare the method for thin film on contact lens to carry out according to the following steps:

[0042] (A01) Firstly, the surface of the base material 21 of the contact lens 2 can be modified by plasma through the plasma device 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com