Elastic vortex-spinning core-spun yarn and production method thereof

A production method, vortex spinning technology, applied in the field of spinning, can solve the problems of high yarn modulus, weak yarn strength, and stiff hand feeling of vortex spinning, and achieve high yarn strength, good elastic recovery performance, soft and comfortable hand feeling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

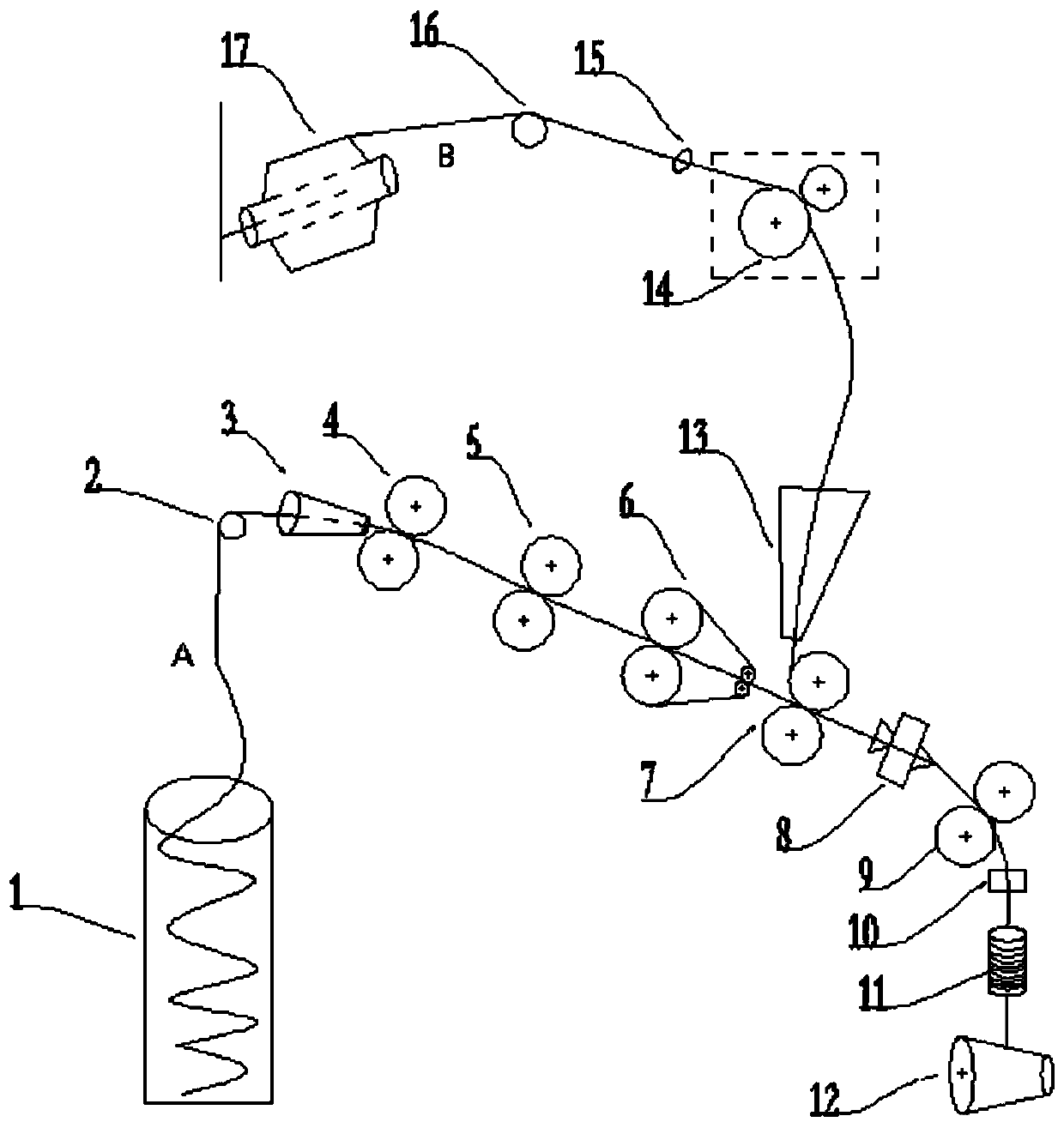

[0037] Disclosed in the application is a production method of elastic vortex spinning core-spun yarn, for adopting such as figure 1 The vortex spinning core-spun yarn spinning device shown; the elastic vortex spinning core-spun yarn spinning device includes a vortex spinning machine platform and a core wire guide device arranged on the upper part of the vortex spinning machine platform;

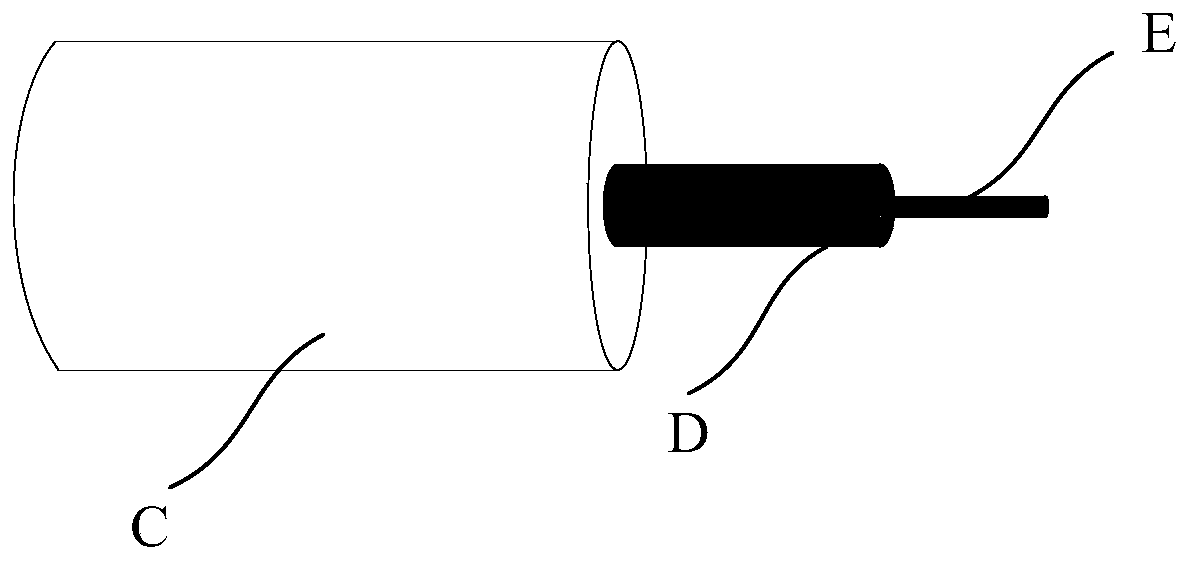

[0038] Along the processing direction of the core wire raw material, the core wire guide device sequentially includes a core wire guide frame, a core wire tension disc 16, a core wire guide hook 15, a core wire tension control member 14, a core wire air flow guiding member 13;

[0039] Along the processing direction of the yarn, the vortex spinning machine platform includes a creel guide 2, a trumpet head bar guide 3, a drafting rear roller and a rear top roller 4 cooperating with the rear roller, a second roller, and a second roller. Matched second top roller 5, third roller and third top r...

Embodiment 2

[0045] The outsourced strands in this application are final drawn strands prepared by the processes of blowing, carding, doubling, coiling, combing, and drawing.

[0046] The uncolored cotton is respectively processed through cleaning, carding, doubling, sliver rolling, combing, and drawing to make uncolored pure cotton end drawing, and the sliver weight is 13.5g / 5m.

[0047] The core yarn is made of 75D white T400 filament and 70D spandex blank composite elastic yarn, the pre-drawing ratio of spandex is 3.5 times, and the proportion of composite elastic yarn spandex is 22%.

[0048]On the pure cotton vortex spinning frame, the natural color pure cotton end is drawn through the bell head guide, and drafted by four pairs of rollers and rollers, with a total draft ratio of 101.6 times; , stainless steel guide wire hook, and then through the tension control device composed of the tension roller and the tension top roller controlled by the servo motor, the pre-drawing ratio of the...

Embodiment 3

[0051] 70% black polyester staple fiber and 30% black viscose staple fiber are respectively processed through cotton blending, cleaning, carding, pre-doubling, and drawing to make black TR end-drawing, and the sliver weight is 13.5g / 5m.

[0052] The core yarn is made of 30D black polyester DTY filament and 20D spandex blank composite elastic yarn, the pre-drawing ratio of spandex is 2.5 times, and the composite elastic yarn spandex accounts for 21%.

[0053] On the vortex spinning frame, the black TR end draws through the horn head guide, and is drafted by four pairs of rollers and rollers, with a total draft ratio of 193.8 times; The wire hook passes through the tension control device composed of the tension roller and the tension top roller controlled by the servo motor. The pre-drawing ratio of the core wire is set to 1.02 times. The strands are collected, and the core yarn and whisker assembly enter the spindle through the nozzle. Under the action of high-speed airflow, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com