Diesel and methanol dual-fuel system of internal combustion locomotive engine and method

A technology of dual-fuel system and internal combustion locomotive, applied in the direction of internal combustion piston engine, combustion engine, machine/engine, etc., can solve the problems of high cost, failure to meet the requirements of locomotive use, and inability to achieve large-scale blending, etc., to achieve improved applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

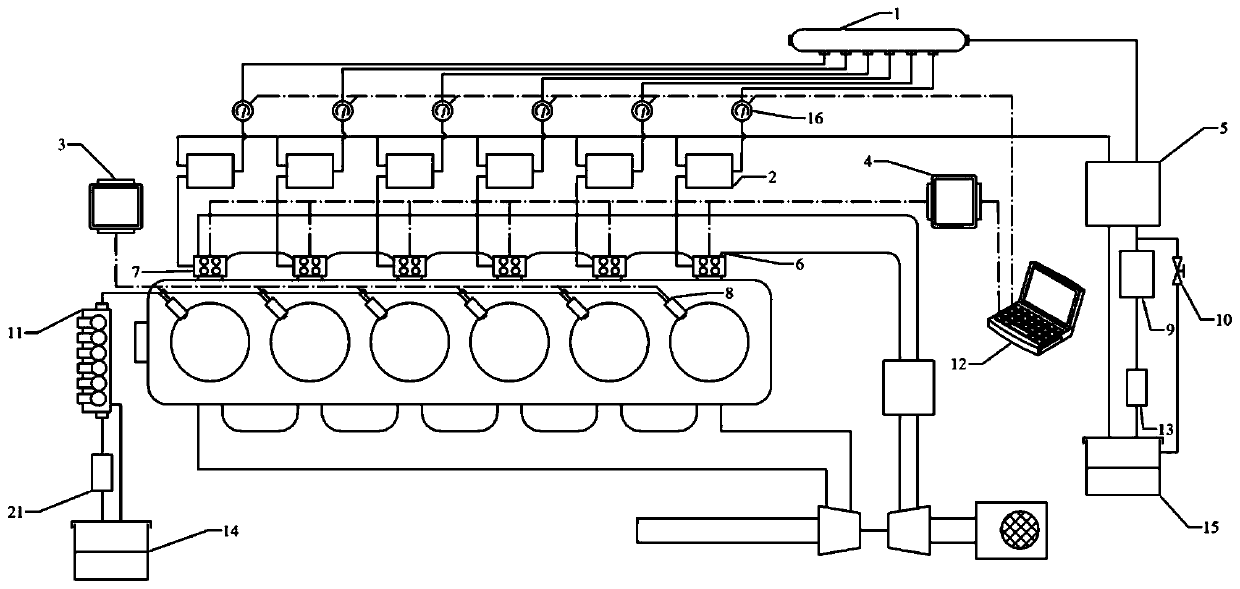

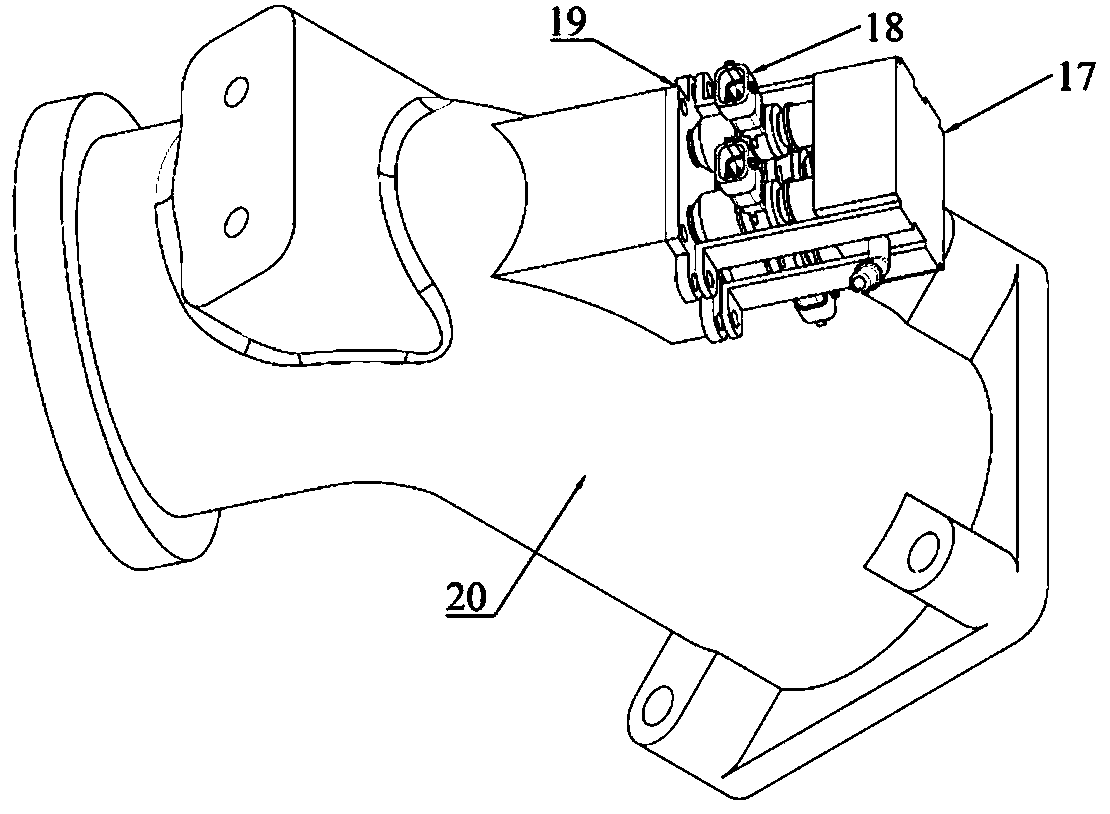

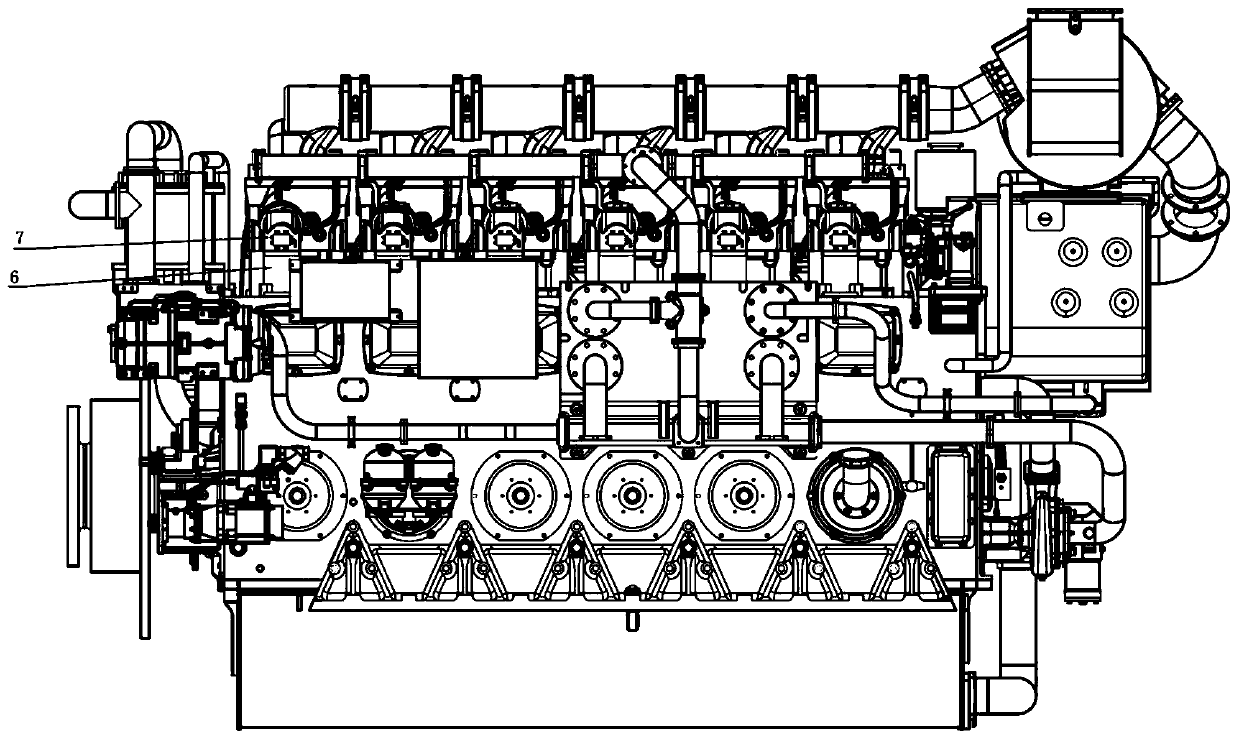

[0037] Such as figure 1 As shown, a diesel-methanol dual-fuel locomotive engine system is disclosed in this embodiment, which includes a locomotive diesel engine, a diesel supply and injection system, a diesel electronic control unit 3, an alcohol injector assembly 7, an alcohol supply system, and methanol injection Control System.

[0038] The locomotive diesel engine model is R6280ZC, bore 280mm, stroke 300mm, in-line 6-cylinder 4-stroke compression ratio is 13, rated speed and power are 1000r / min and 1750kW respectively, the maximum burst pressure in the cylinder is 15.5MPa, the intake pressure after supercharging Up to 3.72bar (absolute pressure).

[0039] The diesel fuel suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com