Ceramic diaphragm and preparation method thereof, and lithium ion battery

A lithium-ion battery and ceramic diaphragm technology, applied in the field of lithium-ion batteries, can solve the problems of affecting the life of lithium-ion batteries, the decrease of battery cycle life, and the decrease of battery performance, so as to improve safety performance and cycle performance, light specific gravity, and reduce wear and tear degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

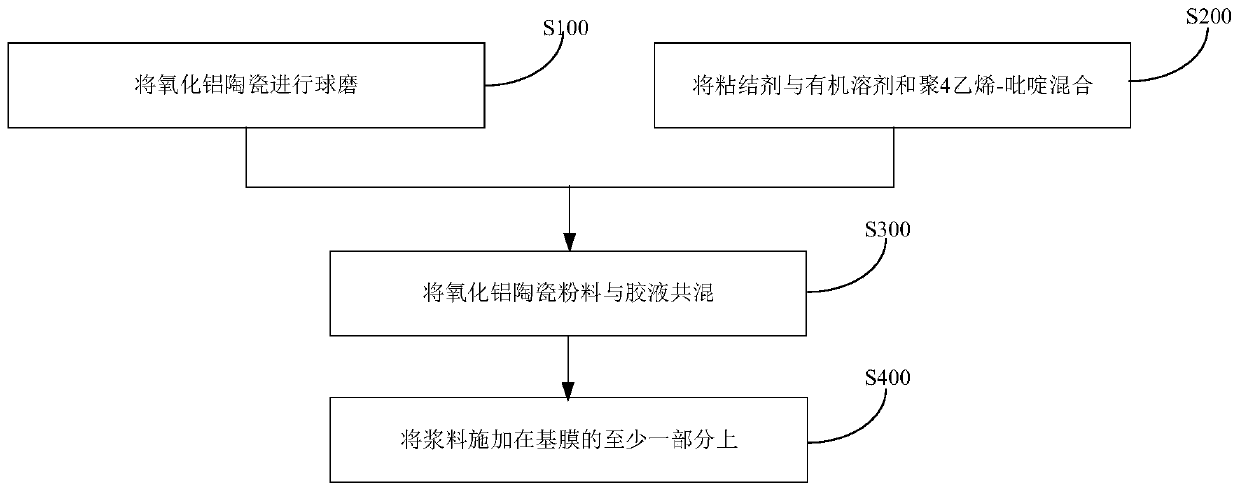

[0058] Preparation method of ceramic diaphragm:

[0059] 1) Mixing of powders: ball milling alumina ceramics for 0.5-2 hours to obtain alumina ceramics powders;

[0060] 2) Preparation of glue solution: Add the binder into the organic solvent, stir in a vacuum environment at a temperature of 30-50°C until the binder is completely dissolved, then add polyvinyl-pyridine until it is completely dissolved, get the glue;

[0061] 3) Preparation of slurry: Add the alumina ceramic powder obtained in the above step 1) to the glue solution in step 2) in a vacuum environment at a temperature of 30-50° C. to obtain the slurry, the slurry The fineness is 20μm;

[0062] 4) Coating: coating the slurry obtained in step 3) on the surface of the base film, and drying in a vacuum oven at a temperature of 50° C. to 90° C. to obtain a ceramic diaphragm.

[0063] Examples 1-3 adopt the above-mentioned preparation method in combination with the parameters in Table 1.

[0064] Table 1

[0065] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com