Porous membrane for membrane distillation and operating method of module for membrane distillation

A membrane distillation and component technology, applied in chemical instruments and methods, membranes, pervaporation, etc., can solve the problem of unclear surface state, membrane distillation module or membrane distillation device water treatment capacity, time-dependent stable transportability, and handleability. Reduce and other problems to achieve the effect of improving water treatment capacity, inhibiting wetting and solute precipitation/residual phenomena, cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

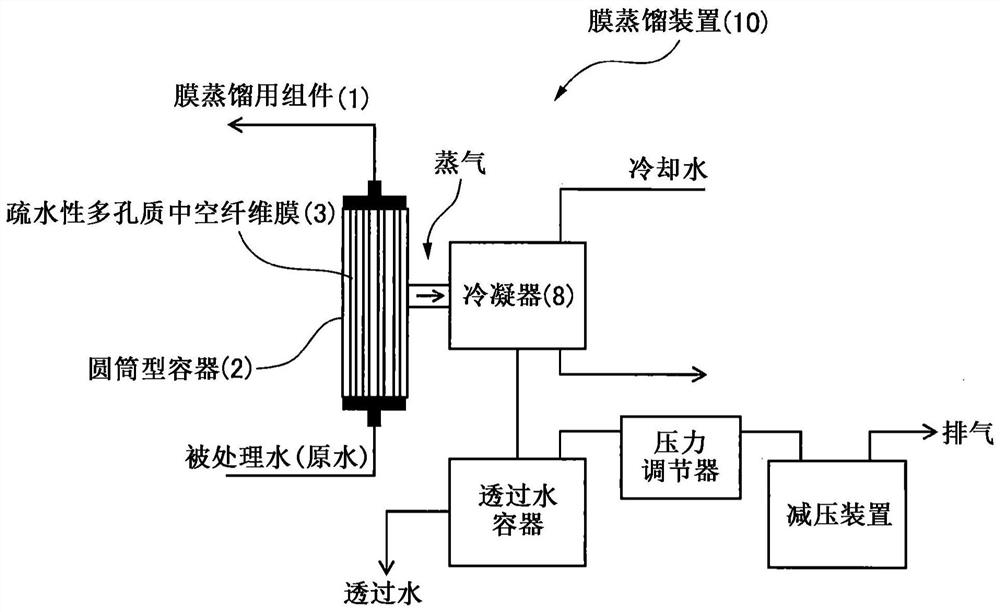

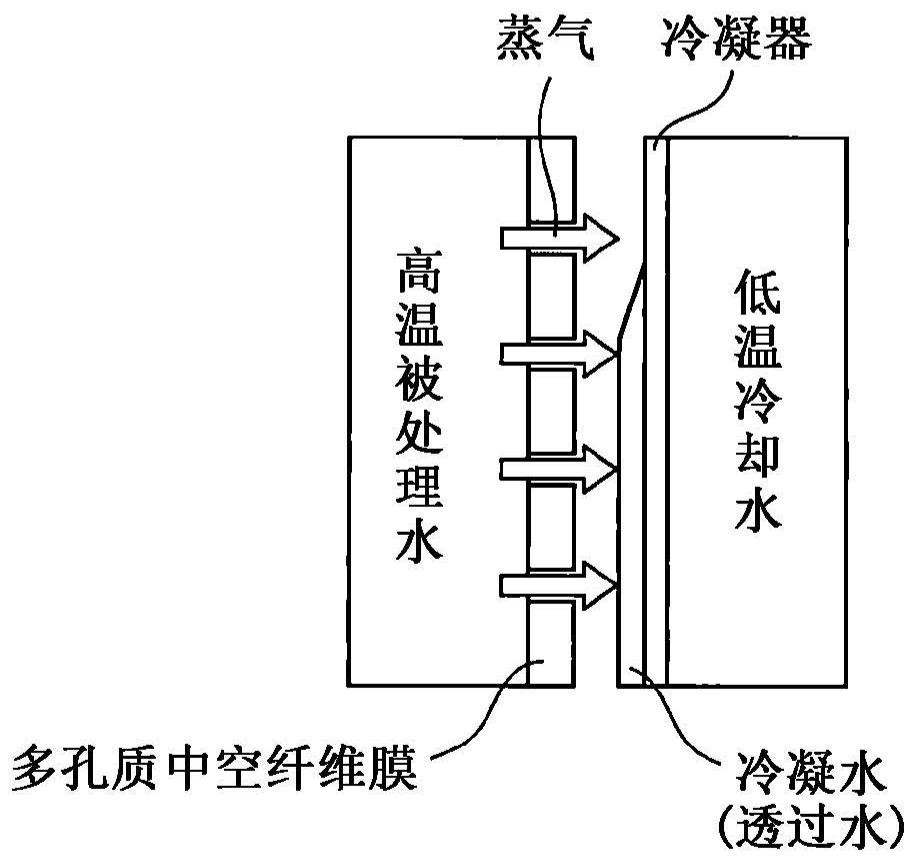

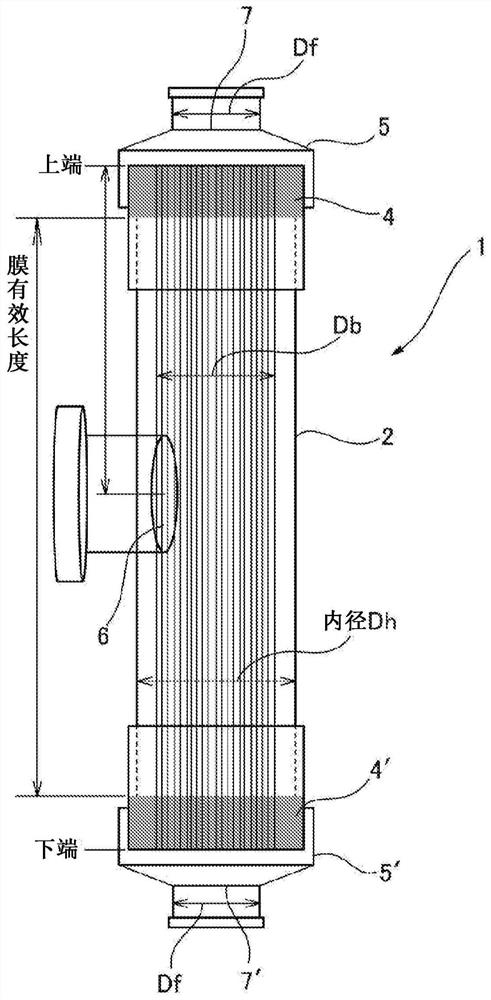

[0691] Put 4,200 polyvinylidene fluoride hollow fiber membranes with an outer diameter of 1.22 mm, an inner diameter of 0.66 mm, and a film thickness of 280 μm in a cylindrical container made of polysulfone with an inner diameter of 128 mm, and bond the hollow fiber membranes to the cylinder with epoxy resin. The gap of the type container was fixed, and a membrane module for membrane distillation with an effective membrane length of 86mm was produced. In addition, 360 stainless steel tubes having an inner diameter of 1 mm, an outer diameter of 1.2 mm, and an effective length of 220 mm were housed in the same container as the above-mentioned cylindrical container to produce a condenser. like figure 1 As shown, the module for membrane distillation and the condenser were connected to each other at one side opening. At this time, the shortest distance between the outer surface of the hollow fiber membrane in the membrane distillation module and the outer surface of the stainless ...

Embodiment 2

[0697] Membrane distillation was performed in the same manner as in Example 1 except that 4400 hollow fiber membranes were used. The structural characteristics of the membrane distillation module used, the operating conditions of the membrane distillation, and the results are shown in Table 1 below. The flux is 14.6kg / m 2 / hr, the permeated water production efficiency was 2.7%, and the conductivity of the obtained permeated water varied in the range of 0.1 to 0.2 μS / cm.

Embodiment 3

[0699] Membrane distillation was performed in the same manner as in Example 1 except that 4600 hollow fiber membranes were used. The structural characteristics of the membrane distillation module used, the operating conditions of the membrane distillation, and the results are shown in Table 1 below. The flux is 13.4kg / m 2 / hr, the permeated water production efficiency was 2.6%, and the conductivity of the obtained permeated water varied in the range of 0.1 to 0.2 μS / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com