Lamellar nanometer barium titanate and preparation method thereof, and applications in sewage treatment based on piezoelectric photocatalysis

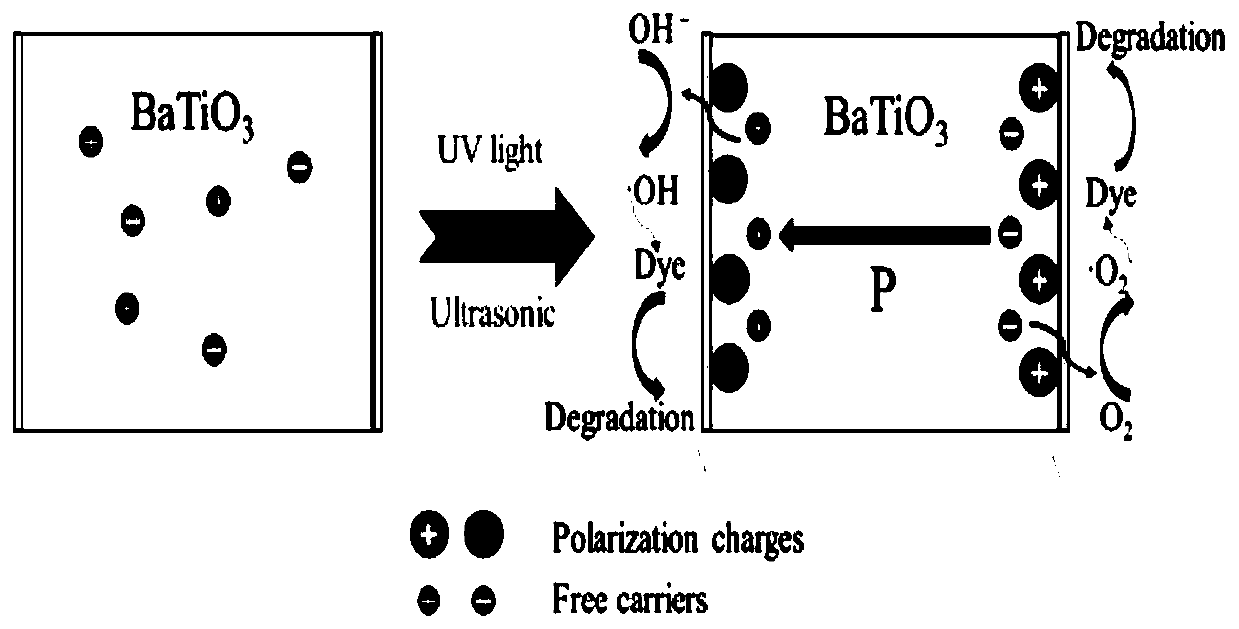

A layered nano-barium titanate technology, applied in the direction of light water/sewage treatment, special compound water treatment, water/sludge/sewage treatment, etc., can solve the problem of reduced redox capacity, limited practical application, low separation efficiency, etc. problems, to achieve the effect of promoting separation, enhancing catalytic oxidation capacity, and wide application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

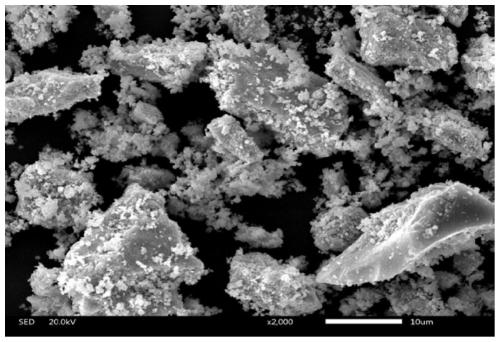

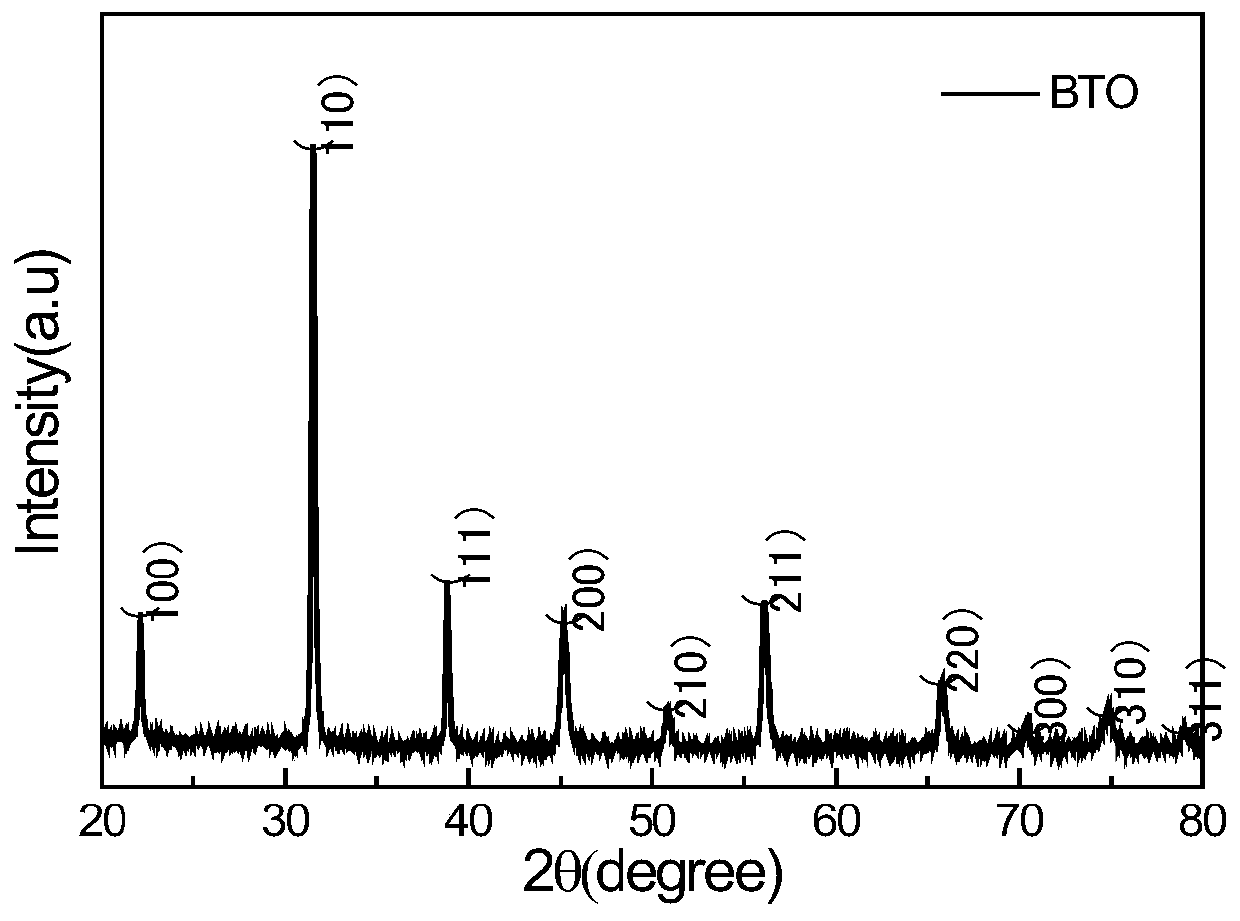

[0044] Sol-gel synthesis of lamellar barium titanate (BTO), the steps are as follows:

[0045] 1) Wash the glass sheet with deionized water and ethanol alternately and repeatedly until there are no obvious impurities on the surface, put it in a vacuum drying oven, dry it, and seal it for later use;

[0046] 2) Weigh 15.35g of tetrabutyl titanate, dissolve it in 50mL of ethanol solution, put the 250mL beaker containing the mixed solution into a magnet, and put it in a magnetic stirrer for 2 hours until it is evenly mixed, and record it as liquid A;

[0047] 3) Dissolve 11.66g of barium acetate in 50mL of acetic acid solution (mixed with 15mL of glacial acetic acid and 35mL of deionized water), stir it with a glass rod for a period of time, and then place it in a water bath at 60°C (at a heating rate of 2°C / min. to 60°C), keep warm for 2 hours, and record it as liquid B;

[0048] 4) Slowly add liquid B to liquid A, then stir magnetically for 1 hour and then let it stand for agi...

Embodiment 2

[0051] Sol-gel synthesis of lamellar barium titanate (BTO), the steps are as follows:

[0052] 1) Wash the glass sheet with deionized water and ethanol alternately and repeatedly until there are no obvious impurities on the surface, put it in a vacuum drying oven, dry it, and seal it for later use;

[0053] 2) Weigh 10-15g of tetrabutyl titanate, dissolve it in 50mL of isopropanol solution, add a magnet to the 250mL beaker containing the mixed solution and put it in a magnetic stirrer for 3-6h until the mixture is evenly mixed. For liquid A;

[0054] 3) Dissolve 12-18g of barium carbonate in 50mL of acetic acid solution (mixed with 15mL of glacial acetic acid and 35mL of deionized water), stir with a glass rod for a period of time and place it in a water bath at 60°C (at a heating rate of 2°C / min rise to 60°C), keep warm for 2 hours, and record it as liquid B;

[0055] 4) Slowly add liquid B to liquid A, then stir magnetically for 1-2 hours, then let it stand for aging to ob...

Embodiment 3

[0058] Sol-gel synthesis of lamellar barium titanate (BTO), the steps are as follows:

[0059] 1) Wash the glass sheet with deionized water and ethanol alternately and repeatedly until there are no obvious impurities on the surface, put it in a vacuum drying oven, dry it, and seal it for later use;

[0060] 2) Weigh 10-15g of tetrabutyl titanate, dissolve it in 50mL of isopropanol solution, add a magnet to the 250mL beaker containing the mixed solution and put it in a magnetic stirrer for 3-6h until the mixture is evenly mixed. For liquid A;

[0061] 3) Dissolve 12-18g of barium acetate in 50mL of acetic acid solution (mixed with 15mL of glacial acetic acid and 35mL of deionized water), stir it with a glass rod for a period of time and place it in a 60°C water bath (at a heating rate of 2°C / min rise to 50°C), keep it warm for 2 hours, and record it as liquid B;

[0062] 4) Slowly add liquid B to liquid A, then stir magnetically for 1-2 hours, then let it stand for aging to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com