Preparation method and applications of self-supported carbon cloth loaded cobaltous selenide nickel nanowires

A technology of nickel nanowires and cobalt selenide, which is applied in the fields of catalysis and energy storage, can solve the problems of high cost of precious metal catalysts, few catalysts, poor stability, etc., and achieves high-efficiency catalytic electrolysis of water for hydrogen evolution and oxygen evolution. High stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

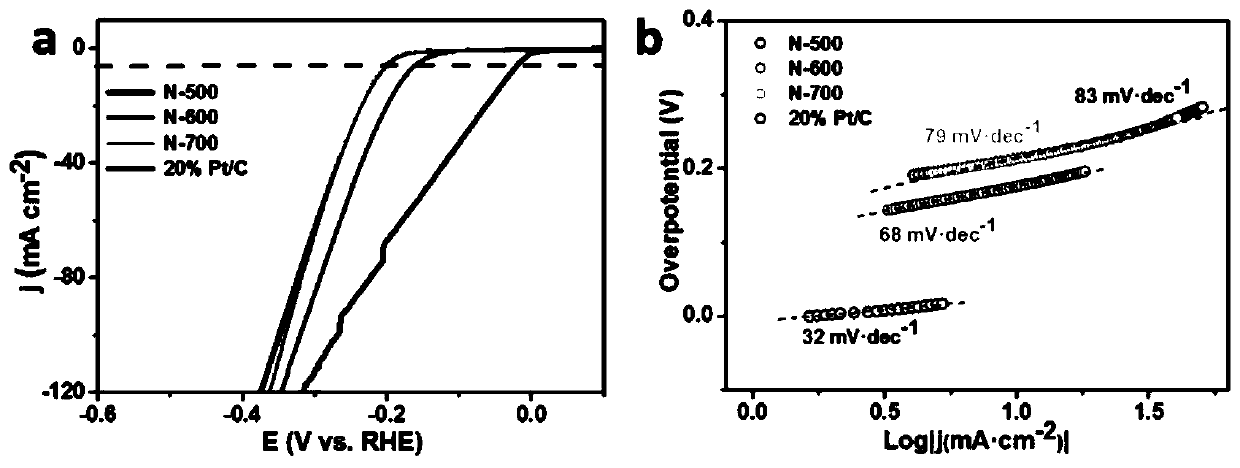

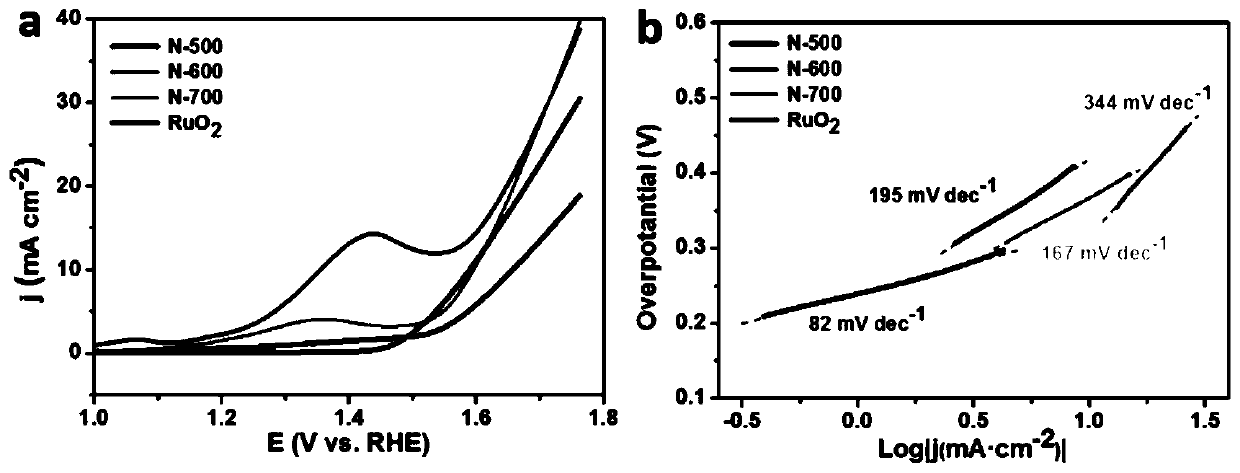

Embodiment 1

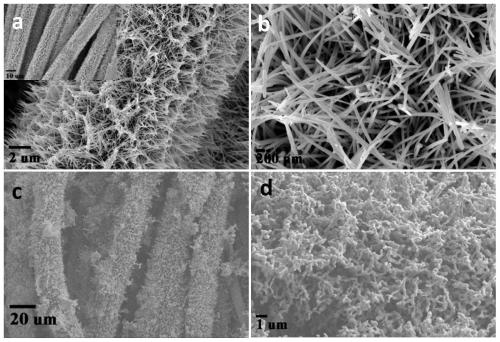

[0032] (1) Measure nitric acid with a mass fraction of 10% and sulfuric acid with a mass fraction of 10% according to the volume ratio of 3:1 with a graduated cylinder, add it to a 50mL beaker and stir evenly to obtain a nitric acid / sulfuric acid mixture; cut 3x3 cm 2 Put the carbon cloth into the solution and soak it completely for 1 hour; after soaking, take out the carbon cloth and wash it repeatedly with deionized water until PH = 7, and dry it in an oven at 60°C to obtain a hydrophilic carbon cloth;

[0033] (2) Weigh 1.45g Co(NO 3 ) 2 , 0.59g NiCl 2 ·6H 2 O, 0.45g H 2 NCONH 2 , added to a beaker containing 35ml of deionized water, stirred evenly with a magnetic stirrer; immersed in the fully wetted hydrophilic carbon cloth into the beaker, and ultrasonically treated for 10 minutes; finally, the carbon cloth and the solution were transferred to the reactor for water For heat treatment, the temperature was raised to 150°C at a heating rate of 5°C / min and kept for 16 h...

Embodiment 2

[0036] (1) with embodiment 1;

[0037] (2) with embodiment 1;

[0038] (3) During the selenization process of the sample, the target temperature was raised to 600°C, and finally marked as SeCoNi NWs / CC-600, and the rest were the same as step (3) of Example 1.

Embodiment 3

[0040] (1) with embodiment 1;

[0041] (2) with embodiment 1;

[0042] (3) During the selenization process of the sample, the target temperature was raised to 700°C, which was marked as SeCoNi NWs / CC-700, and the rest were the same as step (3) of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com