Method used for kitchen waste oil co-pyrolysis extraction with microalgae liquidation multiproducts

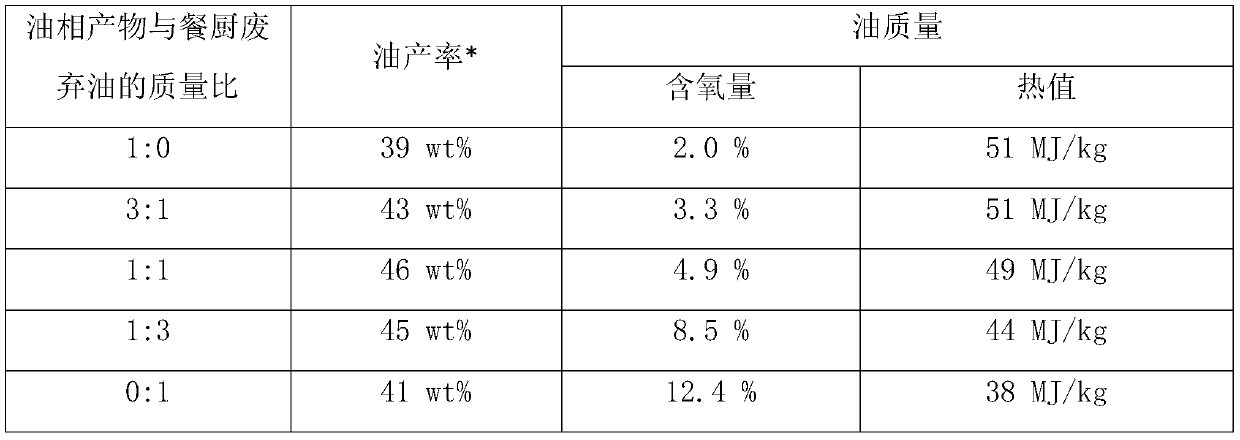

A technology for pyrolysis upgrading and product, applied in the petroleum industry, liquid carbon-containing fuels, fuels, etc., can solve the problems of high coking rate, low hydrocarbon yield, easy deactivation, etc., to achieve low growth cost, reduce Oxygen content in the oil phase and the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

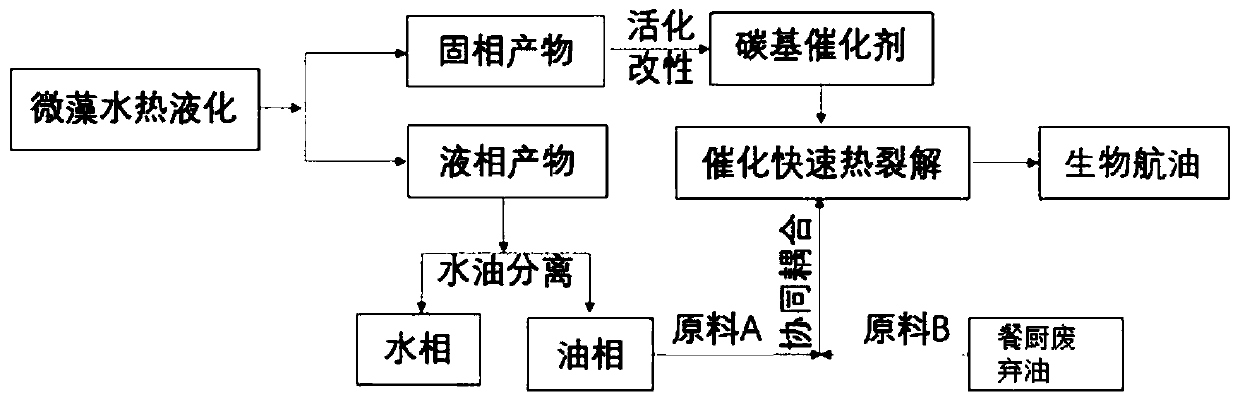

[0022] Such as figure 1 As shown, a kind of microalgae liquefaction multi-products designed in the present invention participates in the method for co-pyrolysis and quality improvement of kitchen waste oil, the specific process is as follows:

[0023] Preparation of raw materials: Chlorella with a water content of 30 to 70% is used in the embodiment of the present invention, and microalgae such as Scenedesmus obliquus and Micromansella can also be used;

[0024] Hydrothermal liquefaction of microalgae: use salt bath to heat the reaction kettle, use thermocouple to control the temperature to 250-35...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com