A kind of elastomer performance testing equipment and elastomer performance testing method

A kind of testing equipment and elastic body technology, which is applied in the direction of elasticity test, machine/structural component test, and application of stable tension/pressure test material strength, etc., which can solve the problem of high purchase cost, high hydraulic noise, and difficulty in popularization and application And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

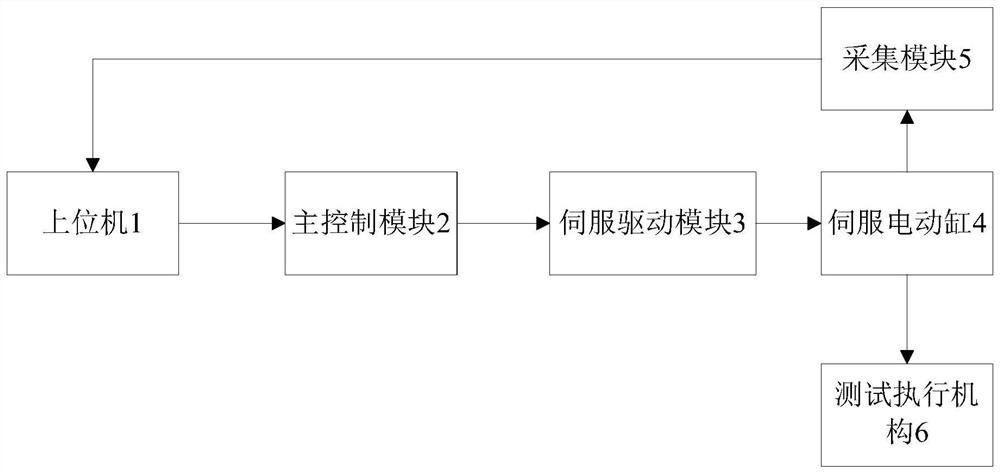

Embodiment 1

[0017]Embodiment 1: A kind of elastic body performance testing equipment, including upper computer 1, main control module 2, servo drive module 3, servo electric cylinder 4, test tooling and acquisition set with evaluation parameters, preload control parameters and test control parameters Module 5, the test fixture includes a test bench (not shown) for placing the elastic body to be tested and a test actuator 6 that is used to apply pressure to the elastic body to be tested. The movement is set on the test bench, and the host computer 1 sends a preload control The parameters and test control parameters are sent to the main control module 2. The main control module 2 analyzes the corresponding preload control instructions according to the preload control parameters and sends them to the servo drive module 3. The servo drive module 3 controls the servo electric cylinder 4 according to the preload control instructions. The output rod synchronously drives the test actuator 6 to app...

Embodiment 2

[0018] Embodiment 2: the rest is the same as Embodiment 1, the difference is that the preloading mode is the pressure loading mode, the preloading movement interval is the preloading pressure interval, the preloading target value is the preloading pressure target value, and the test loading mode is Pressure loading mode, the test movement interval is the test pressure movement interval.

Embodiment 3

[0019] Embodiment three: use the elastomer performance testing method of the elastomer performance testing equipment of embodiment one, comprise the following steps:

[0020] 1): The elastic body to be tested is fixedly placed on the test bench, and the main control module 2 controls the output rod of the servo electric cylinder 4 to run to the set preload starting position at the set preload speed through the servo drive module 3 ;

[0021] 2): The main control module 2 controls the output rod of the servo electric cylinder 4 to drive the test actuator 6 to apply preloading action to the elastic body to be tested in the preloading motion range until the set preloading cycle is reached. After the cycle, the main control module 2 controls the output rod of the servo electric cylinder 4 to drive the test actuator 6 to run at the set preload speed to a position corresponding to the set preload target value, and use this position as the starting point of the test;

[0022] 3): Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com