A flexible high-precision parabolic antenna and its preparation method

A parabolic antenna, high-precision technology, applied in the direction of antenna, radiation element structure, electrical components, etc., can solve the problems of repeated use, poor reliability, poor mobility, etc., to provide portability, improve surface accuracy, The effect of good conformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

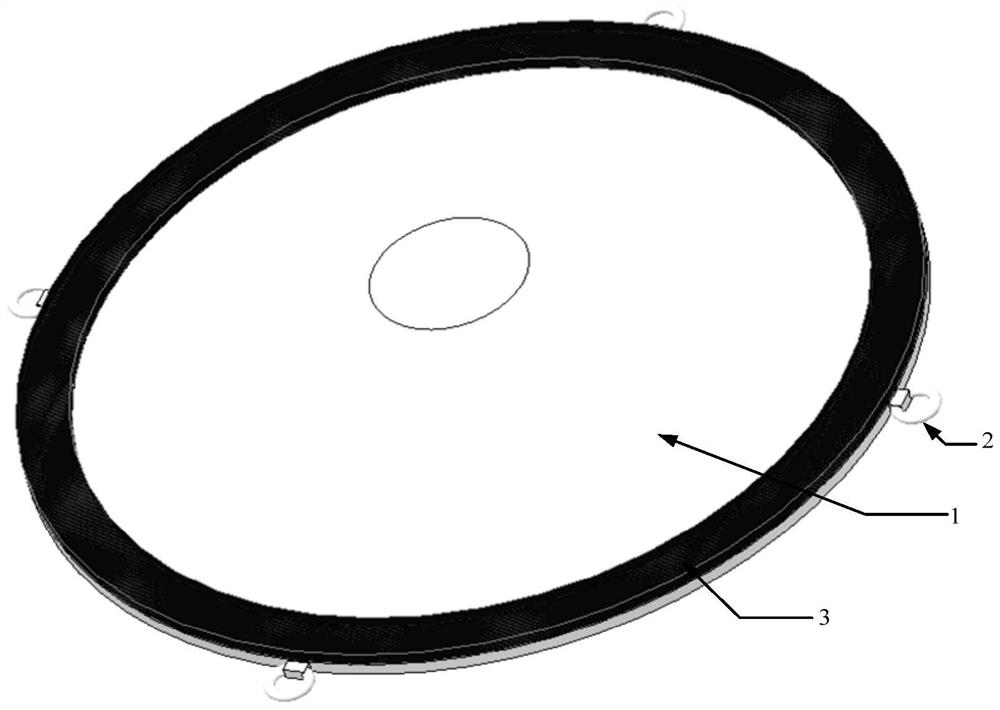

[0037] A method for preparing a flexible high-precision parabolic antenna, comprising the steps of:

[0038] Step (1): Processing and making Invar molds, and cleaning the surface of the molds with acetone;

[0039] Step (2): respectively select flexible sealing film material, flexible hot melt adhesive film and flexible parabolic antenna material for use;

[0040] Step (3): Put the mold into the oven to preheat;

[0041] Step (4): Brush release agent on the preheated mold surface, and follow the order of flexible sealing film layer, flexible hot melt adhesive film layer, flexible parabolic antenna layer, flexible hot melt adhesive film layer, and flexible sealing film layer Make layers.

[0042] Step (5): Vacuumize after laying, and enter the oven at the same time, and keep warm for 30 minutes after the mold is heated to 140°C;

[0043] Step (6): continue to evacuate and cool to room temperature, then demould, and finally trim the edges to prepare a high-precision parabolic...

Embodiment

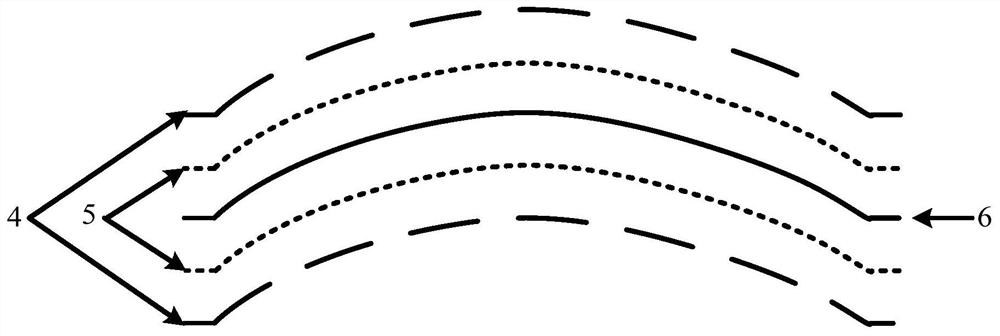

[0046] The material of the flexible sealing film layer 4 is a thermoplastic polyurethane film with a melting point of 150° C. and a thickness of 0.1 mm. The material of the flexible hot-melt adhesive film layer 5 is a thermoplastic polyurethane film with a melting point of 110° C. and a thickness of 0.15 mm. The material of the flexible parabolic antenna layer 6 is a four-way elastic cloth woven with silver-plated nylon fibers, with a thickness of 0.1 mm.

[0047] The preparation method of the flexible high-precision parabolic antenna in this embodiment is as follows:

[0048] Step (1): Processing and making Invar molds, and cleaning the surface of the molds with acetone;

[0049]Step (2): respectively select flexible sealing film layer material, flexible hot melt adhesive film layer and flexible parabolic antenna layer material for use;

[0050] Step (3): Put the Invar mold into the oven and preheat it to 70°C;

[0051] Step (4): Brush the release agent on the surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com