Environment-friendly aqueous film-forming foam extinguishing agent based on C6 type fluorocarbon surfactant

A surfactant and foam fire extinguishing agent technology, applied in fire prevention equipment, etc., can solve the problems of discounted performance of aqueous film-forming foam, high cost, and high concentration of fluorocarbon surfactants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

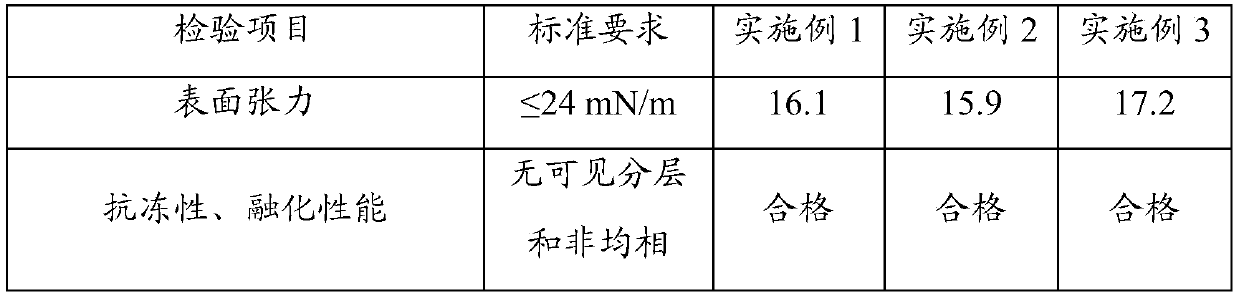

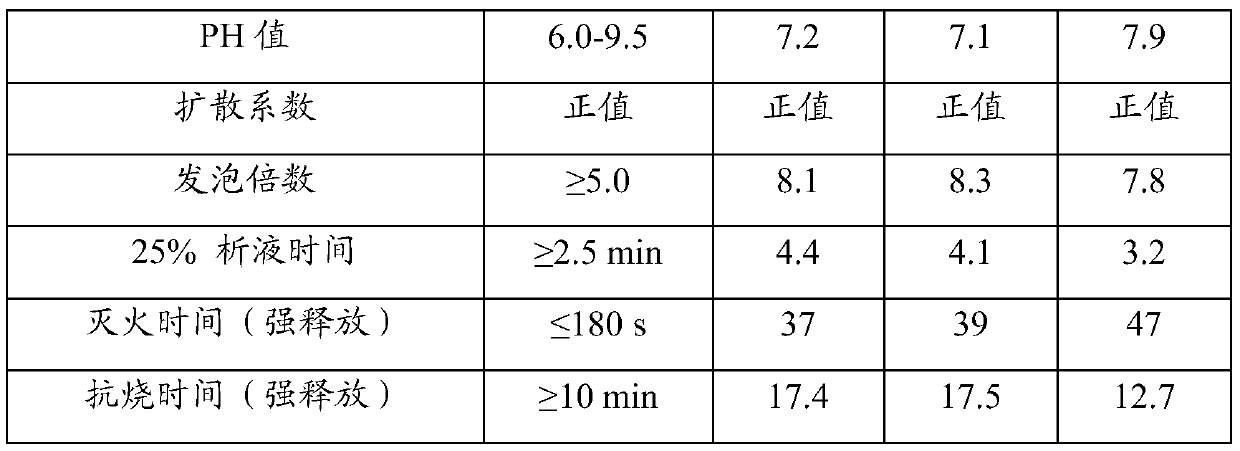

Embodiment 1

[0039] Embodiment 1: the preparation of aqueous film-forming foam fire extinguishing agent (1 ton, 3% type)

[0040] Add 40kg of perfluorooctyl sulfonamide alkyl betaine to the reaction kettle, then add 750kg of industrial soft water and fully stir and mix; under stirring, add 50kg of polyethylene glycol p-isooctylphenyl ether, 6kg Sodium alginate diester, 100kg tetraethylene glycol dimethyl ether, 2kg tetrasodium iminodisuccinate, 2kg potassium 2,4-hexadienoate, after stirring and mixing, adjust the pH value of the solution to 7 with ammonia water or acetic acid, and then replenish Process soft water until the total weight is 1 ton, and stir evenly to obtain an aqueous film-forming foam fire extinguishing agent.

Embodiment 2

[0041] Embodiment 2: the preparation of aqueous film-forming foam fire extinguishing agent (1 ton, 3% type)

[0042] Add 40kg of perfluorooctyl sulfonamide alkyl betaine to the reactor, then add 750kg of industrial soft water and fully stir and mix; under stirring, add 50kg of oligomeric D-glucopyranose and 6kg of linseed gum to the reactor respectively . The weight is 1 ton, and the mixture is evenly stirred to obtain an aqueous film-forming foam fire extinguishing agent.

Embodiment 3

[0043] Embodiment 3: the preparation of aqueous film-forming foam fire extinguishing agent concentrate (1 ton, 6% type)

[0044] Add 20kg perfluorooctyl thiopropionamido alkyl sulfonate to the reactor, then add 750kg industrial soft water and fully stir and mix; under stirring, add 30kg oligomeric D-glucopyranose, 3kg sodium alginate diester, 50kg butyl carbitol, 1kg diaminoethylene tetraacetate, 1kg sodium biacetate, after stirring and mixing, use ammonia water or acetic acid to adjust the pH value of the solution to 7, and then add industrial soft water to The total weight is 1 ton, and the mixture is evenly stirred to obtain an aqueous film-forming foam fire extinguishing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com