Novel ABC dry powder extinguishing agent and preparation method thereof

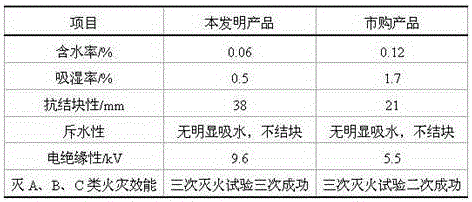

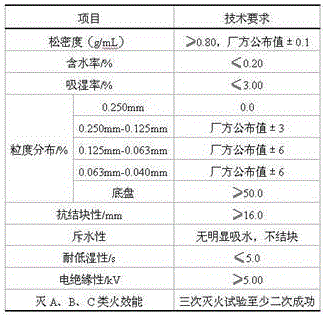

A dry powder fire extinguishing agent, a new type of technology, applied in fire prevention equipment, etc., can solve the problems of low fire extinguishing efficiency, high moisture absorption rate, shortened shelf life, etc., achieve superior fire extinguishing performance, simple preparation method, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1 The new ABC dry powder fire extinguishing agent is mainly prepared from the following raw materials (5kg each): 14 parts of alkali residue, 36 parts of potassium sulfate, 25 parts of sodium oxalate, 8 parts of limestone, 5 parts of magnesium carbonate powder, 6 parts of methyl silicone oil, 7 parts of ammonium sulfate, 4 parts of zinc borate, 2 parts of tin oxide, 3 parts of graphite powder, 1 part of fly ash. The preparation method of the above new ABC dry powder fire extinguishing agent is:

[0024] (1) Take the alkali slag and limestone into a ball mill, grind and grind for 1 hour, take out the dust and pass through a 100-mesh sieve;

[0025] (2) Soak the graphite powder in an acetic acid solution with a concentration of 45% for 30 minutes, take it out and dry it at a constant temperature of 100°C, and crush it through a 200-mesh sieve;

[0026] (3) Add potassium sulfate, sodium oxalate, magnesium carbonate powder, ammonium sulfate, zinc borate and tin oxide into...

Embodiment 2

[0028] Example 2 The new ABC dry powder fire extinguishing agent is mainly prepared from the following raw materials (5kg each): 22 parts of alkali residue, 48 parts of potassium sulfate, 35 parts of sodium oxalate, 14 parts of limestone, 10 parts of magnesium carbonate powder, 9 parts of methyl silicone oil, 13 parts of ammonium sulfate, 8 parts of zinc borate, 5 parts of tin oxide, 6 parts of graphite powder, 5 parts of fly ash. The preparation method of the above new ABC dry powder fire extinguishing agent is:

[0029] (1) Take the alkali slag and limestone into a ball mill, grind and grind for 3 hours, take out the dust and pass through a 160-mesh sieve;

[0030] (2) Soak the graphite powder in an acetic acid solution with a concentration of 45% for 50 minutes, take it out and dry it at a constant temperature of 140°C, and crush it through a 200-mesh sieve;

[0031] (3) Add potassium sulfate, sodium oxalate, magnesium carbonate powder, ammonium sulfate, zinc borate and tin oxide...

Embodiment 3

[0033] Example 3 The new ABC dry powder fire extinguishing agent is mainly prepared from the following raw materials (5kg each): 16 parts of alkali residue, 40 parts of potassium sulfate, 28 parts of sodium oxalate, 10 parts of limestone, 6 parts of magnesium carbonate powder, 7 parts of methyl silicone oil, 9 parts of ammonium sulfate, 5 parts of zinc borate, 3 parts of tin oxide, 4 parts of graphite powder, 2 parts of fly ash. The preparation method of the above new ABC dry powder fire extinguishing agent is:

[0034] (1) Take the alkali residue and limestone into a ball mill, grind and grind for 1.5 hours, remove the dust and pass through a 120-mesh sieve;

[0035] (2) Soak the graphite powder in an acetic acid solution with a concentration of 45% for 35 minutes, take it out and dry it at a constant temperature of 110°C, and crush it through a 200-mesh sieve;

[0036] (3) Add potassium sulfate, sodium oxalate, magnesium carbonate powder, ammonium sulfate, zinc borate and tin oxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com