Preparation method of sulfydryl modified magnetic nano material for adsorbing mercury

A technology of mercapto modification and magnetic nanotechnology, which is applied in the field of preparation of magnetic ferric oxide nanomaterials, can solve problems such as poor selectivity and matrix interference, and achieve the effects of large adsorption capacity, good selectivity, and saving processing time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

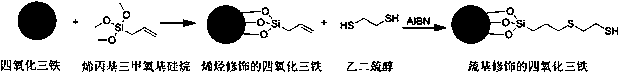

[0019] A kind of preparation operation steps of the mercapto-modified magnetic nanomaterials for adsorbing mercury are as follows:

[0020] (1) Synthesis of olefin-modified magnetic ferric iron tetroxide (Fe 3 o 4 )Nanoparticles:

[0021] 1g of magnetic ferric oxide (Fe 3 o 4 ) nanoparticles were dispersed in 100mL isopropanol and 8mL water, ultrasonically dispersed for 15min, and stirred at room temperature under nitrogen gas. Then add 10 mL of ammonia water (26% w / w), stir for 5 min, add 8 mL of allyltrimethoxysilane, heat to 45°C and stir for 12 h; the product is obtained by magnetic separation, washed three times with deionized water and once with ethanol, 60 ℃ and dried under vacuum for 12 hours to obtain olefin-modified magnetic ferric iron tetroxide (Fe 3 o 4 )Nanoparticles.

[0022] (2) Synthesis of sulfhydryl-modified ferric iron tetroxide Fe 3 o 4 @SiO 2 @SH nanoparticles:

[0023] 1g of olefin-modified magnetic ferric iron tetroxide (Fe 3 o 4 ) nanopart...

Embodiment 2

[0025] A kind of preparation operation steps of the mercapto-modified magnetic nanomaterials for adsorbing mercury are as follows:

[0026] (1) Synthesis of olefin-modified Fe 3 o 4 Nanoparticles:

[0027] 1g of magnetic iron tetroxide (Fe 3 o 4 ) nanoparticles were dispersed in 100mL isopropanol and 8mL water, ultrasonically dispersed for 15min, and stirred at room temperature under nitrogen gas. Then add 10 mL of ammonia water (26% w / w), stir for 5 min, add 8 mL of allyltrimethoxysilane, heat to 45°C and stir for 12 h. The product was obtained by magnetic separation, washed three times with deionized water, washed once with ethanol, and dried under vacuum at 60°C for 12 hours to obtain olefin-modified Fe 3 o 4 Nanoparticles.

[0028] (2) Synthesis of sulfhydryl-modified ferric iron tetroxide Fe 3 o 4 @SiO 2 @SH nanoparticles:

[0029] 1 g of olefin-modified Fe 3 o 4 Nanoparticles were dissolved in 100mL of toluene, nitrogen was blown, and stirred at room tempera...

Embodiment 3

[0031] A kind of preparation operation steps of the mercapto-modified magnetic nanomaterials for adsorbing mercury are as follows:

[0032] (1) Synthesis of olefin-modified Fe 3 o 4 Nanoparticles:

[0033] 1g of magnetic iron tetroxide (Fe 3 o 4 ) rice particles were dispersed in 100mL of isopropanol and 8mL of water, ultrasonically dispersed for 15min, and stirred at room temperature under nitrogen gas. Add 10 mL of ammonia water (26% w / w), stir for 5 min, add 8 mL of allyltrimethoxysilane, heat to 45°C and stir for 12 h. The product was obtained by magnetic separation, washed three times with deionized water, washed once with ethanol, and dried under vacuum at 60°C for 12 hours to obtain olefin-modified Fe 3 o 4 Nanoparticles.

[0034] (2) Synthesis of sulfhydryl-modified ferric iron tetroxide Fe 3 o 4 @SiO 2 @SH nanoparticles:

[0035] 1 g of olefin-modified Fe 3 o 4 Nanoparticles were dissolved in 100mL of toluene, nitrogen was blown, and stirred at room tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com