Method and system for manufacturing composite material based on two-component adhesive

A manufacturing method and technology of composite materials, applied in the direction of adhesives, adhesive types, chemical instruments and methods, etc., can solve problems such as increased equipment costs, large amount of organic solvent usage, and harmful residues of composite materials, so as to improve manufacturing efficiency, Effect of reducing reagent cost and equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] In this embodiment, the method of the present invention is described by taking a solar battery backsheet prepared by compounding two-component adhesives as an example. In this embodiment, a solar battery backsheet laminated with PDVF+PET+PE is used as an example to illustrate. In other embodiments, the method and system of this embodiment can be used to make PDVF+PET+PDVF backboard, PVF+PET+PE backboard, PVF+PET+PVF backboard, PDVF+PET+P VF backboard, etc. .

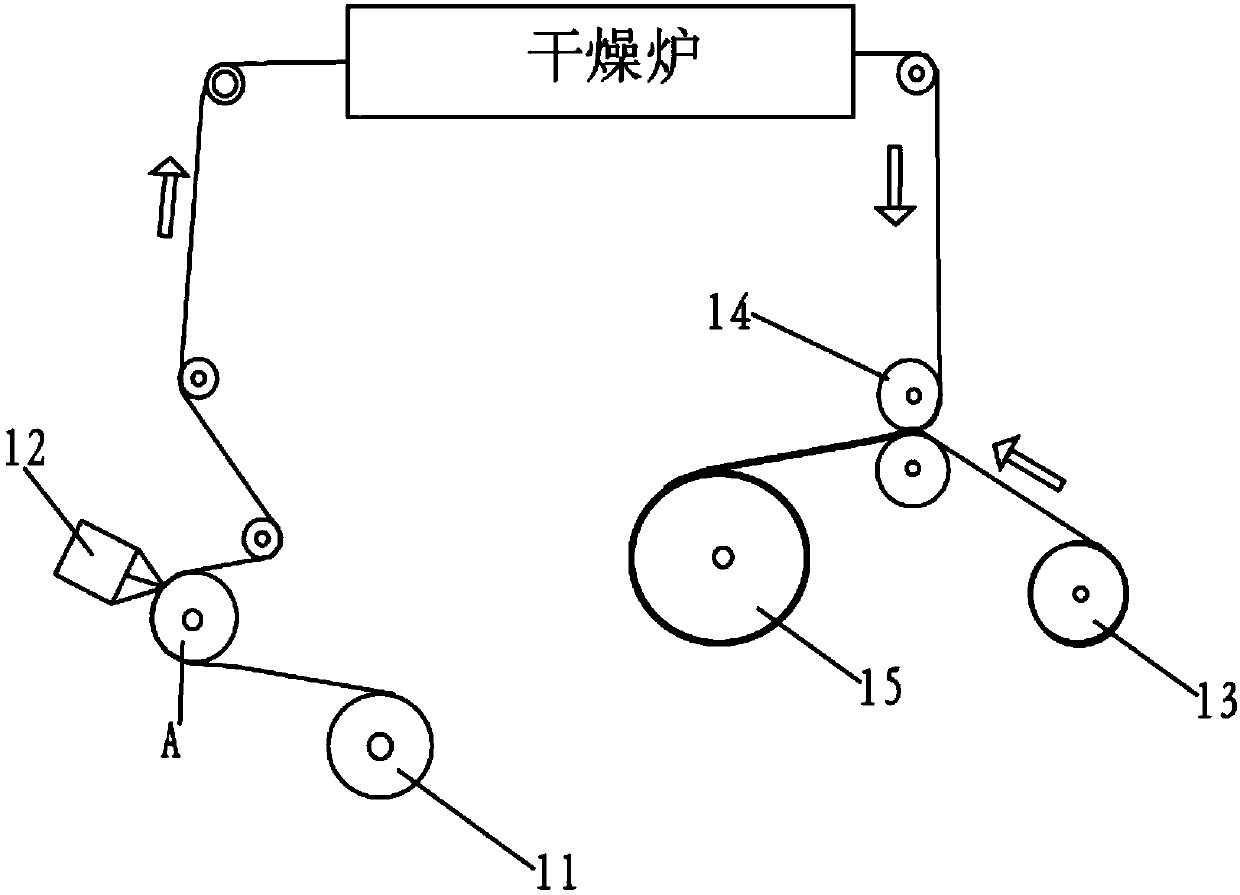

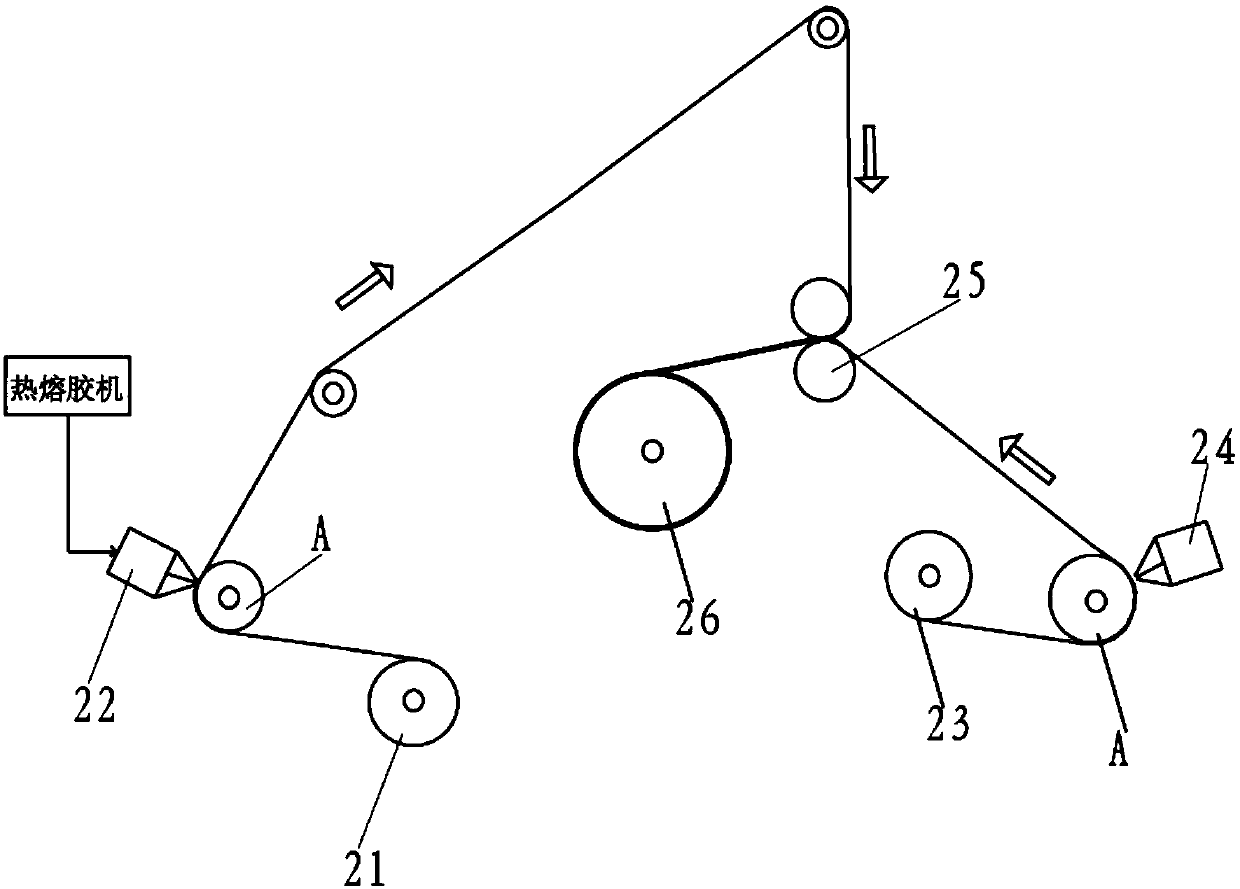

[0050] Such as figure 1 As shown, the PET film material 21 is stretched straight through the tension shaft after unwinding and bypassed from the support roller A, where a hot melt adhesive coating device 22 is provided, and the hot melt adhesive coating device 22 is connected to the support roller A. A is close, and the hot-melt adhesive coating device 22 is connected to a hot-melt adhesive machine through a rubber delivery pipe, and the hot-melt resin heated in the hot-melt adhesive machine into a fluid state is...

Embodiment 2

[0073] The difference between this embodiment and Embodiment 1 is that a non-hot-melt two-component adhesive is used. Wherein the surface of the PET film 21 is coated with component A, and the surface of the PE film 23 is coated with component B. Component A does not need to be connected to a hot-melt adhesive machine. Since the coated components A and B are in a fluid state at room temperature, they can be directly coated, and then laminated by laminating rollers 25 to obtain intermediate film materials. Other operations are the same as in Example 1, except that the two-component adhesive used in this example is a cold glue type adhesive.

[0074] The composition of component A is in parts by mass: 180-220 parts of methyl methacrylate (industrial), 30 parts of hydroxyethyl methacrylate (industrial), 35-50 parts of ABS (solid, industrial), cumene peroxidation Hydrogen (industrial) 15 parts, methacrylate reinforcing agent 15 parts.

[0075] The composition of part B is in par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com