Manufacturing process of wear-resistant glass fiber cloth

A technology of glass fiber cloth and manufacturing process, which is applied in the direction of wear-resistant fiber, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of limited use effect of glass fiber cloth, limit the scope of application, reduce the strength of glass fiber, etc., and achieve Effects of enhancing wear resistance, enhancing toughness and strength, and enhancing softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

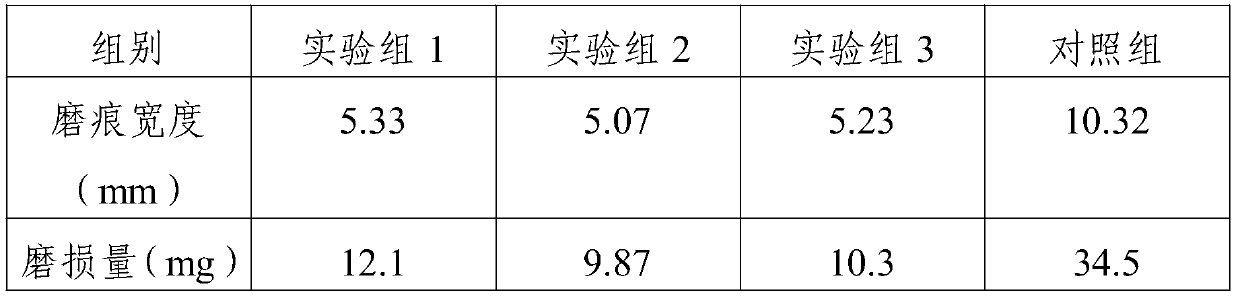

Examples

Embodiment 1

[0031] A manufacturing process of wear-resistant glass fiber cloth, characterized in that it comprises the following manufacturing steps:

[0032] (1) Select clean glass balls and pour them into the melting furnace, then add zirconium dioxide, titanium dioxide and graphite, and adjust the temperature to 1400°C to completely melt the material;

[0033] (2) drawing the melted glass to obtain rough glass fibers, and cleaning them with ultrasonic vibration in an ultrasonic cleaning machine to obtain prefabricated glass fibers for future use;

[0034] (3) The above-mentioned prefabricated glass fiber is sheared and crushed in a shearing machine, and then basalt fiber and carbon fiber are added for high-temperature premixing, and then melted and drawn again, and paraffin oil is added to an ultrasonic machine for constant temperature ultrasonic cleaning at 60-80°C to obtain Raw silk spare;

[0035] (4) Mix and stir the modified epoxy resin and the coupling agent evenly to obtain a m...

Embodiment 2

[0043] A manufacturing process of wear-resistant glass fiber cloth, characterized in that it comprises the following manufacturing steps:

[0044] (1) Select clean glass balls and pour them into the melting furnace, then add zirconium dioxide, titanium dioxide and graphite, and adjust the temperature to 1400°C to completely melt the material;

[0045] (2) drawing the melted glass to obtain rough glass fibers, and cleaning them with ultrasonic vibration in an ultrasonic cleaning machine to obtain prefabricated glass fibers for future use;

[0046](3) The above prefabricated glass fiber is sheared and pulverized in a shearing machine, then basalt fiber and carbon fiber are added for high-temperature premixing, and then melted and drawn again, and paraffin oil is added to an ultrasonic machine for constant temperature ultrasonic cleaning at 60°C to obtain the original silk spare;

[0047] (4) Mix and stir the modified epoxy resin and the coupling agent evenly to obtain a mixed s...

Embodiment 3

[0055] A manufacturing process of wear-resistant glass fiber cloth, characterized in that it comprises the following manufacturing steps:

[0056] (1) Select clean glass balls and pour them into the melting furnace, then add zirconium dioxide, titanium dioxide and graphite, and adjust the temperature to 1400°C to completely melt the material;

[0057] (2) drawing the melted glass to obtain rough glass fibers, and cleaning them with ultrasonic vibration in an ultrasonic cleaning machine to obtain prefabricated glass fibers for future use;

[0058] (3) The above-mentioned prefabricated glass fiber is sheared and crushed in a shearing machine, and then basalt fiber and carbon fiber are added for high-temperature premixing, and then melted and drawn again, and paraffin oil is added to an ultrasonic machine for constant temperature ultrasonic cleaning at 60-80°C to obtain Raw silk spare;

[0059] (4) Mix and stir the modified epoxy resin and the coupling agent evenly to obtain a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com