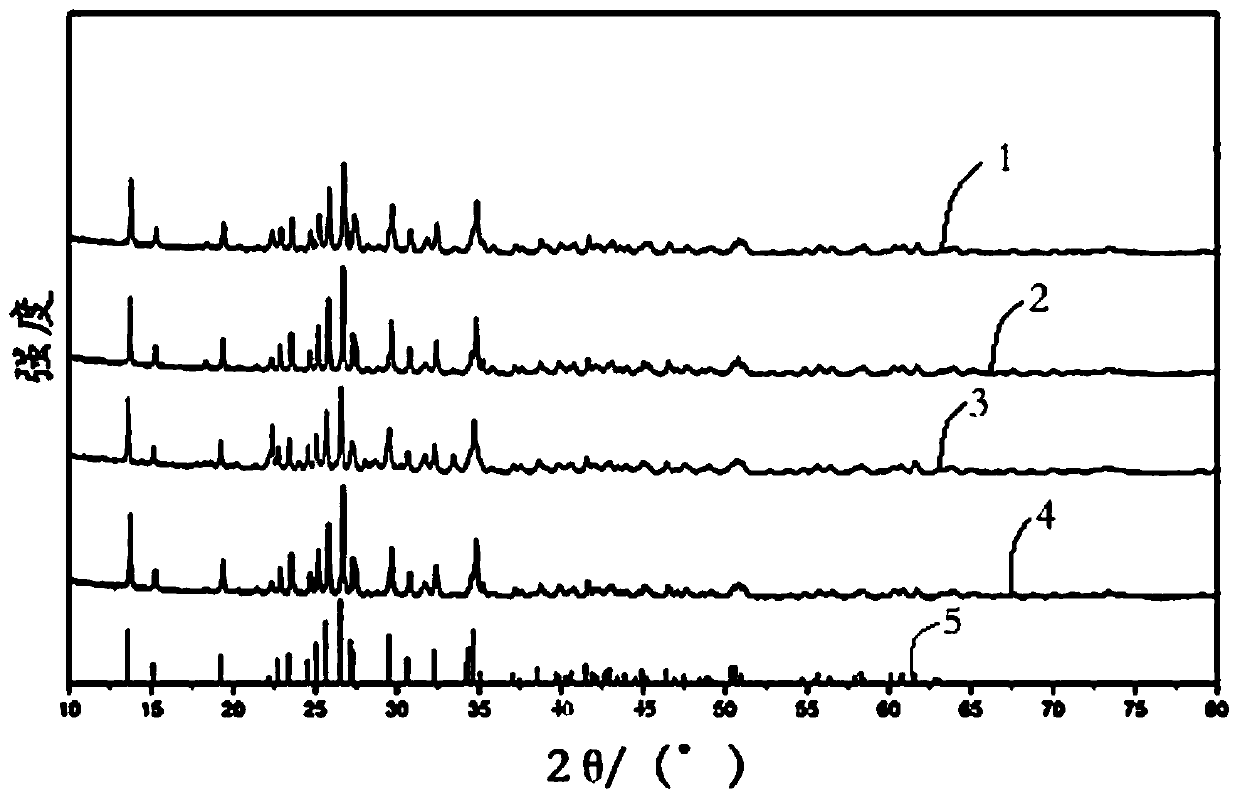

Monoclinic barium feldspar ceramic with low thermal expansion coefficient and preparation method

A low thermal expansion coefficient, barium feldspar technology, applied in the field of ceramics, can solve problems such as impure crystal phase, and achieve the effect of less quantity, small pore size and low thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

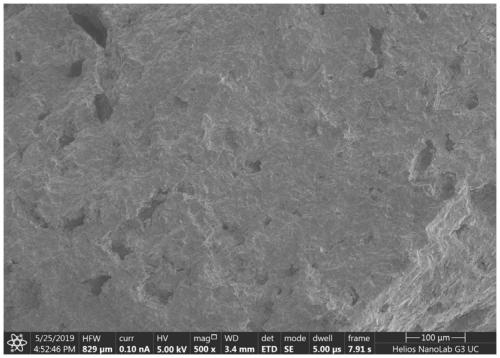

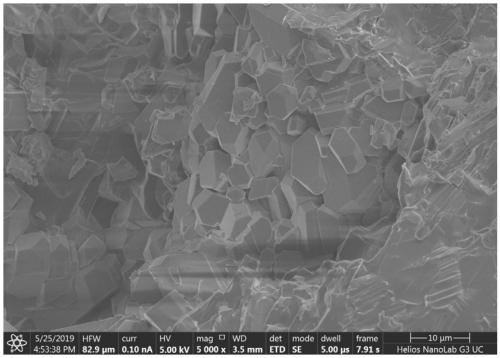

Image

Examples

Embodiment 1

[0056] 1) Provide 48.1wt% of kaolin, 46.9wt% of barium carbonate, and 5wt% of alumina to obtain frit raw materials.

[0057] 2) Add 5% lithium fluoride by weight to the above-mentioned frit raw materials, mix them in a blender, put them into a platinum dry pot, and raise the temperature of the silicon-molybdenum rod lifting electric furnace to 1550 ° C, put the crucible Put it in, keep it warm for 1 hour, and melt it to obtain a uniform and clear barium feldspar glass liquid. Pour the glass liquid into water to quench it, beat the quenched barium feldspar glass into small pieces with a mortar and put it into a polyurethane ball mill jar , with water as the dispersant, zirconia balls as the ball milling medium, the weight ratio of the balls to the material is about 3:1, and ball milled on a fast mill; the ball-milled slurry in the polyurethane ball mill tank is passed through a 60-mesh sieve, and transferred to the enamel iron place in an electric blast drying oven at 120° C., ...

Embodiment 2

[0066] 1) Provide 50.7wt% of kaolin, 44.5wt% of barium carbonate, and 4.8wt% of alumina to obtain frit raw materials.

[0067] 2) Add 10% by weight lithium fluoride to the above-mentioned frit raw materials, mix them in a blender, put them into a platinum dry pot, and raise the temperature of the silicon-molybdenum rod lifting electric furnace to 1500°C, put the crucible Put it in, keep it warm for 1.5h, melt to obtain uniform and clear barium feldspar glass liquid, pour the glass liquid into water and quench it, beat the quenched barium feldspar glass into small pieces with a mortar and put it into a polyurethane ball mill jar In the process, water is used as a dispersant, zirconia balls are used as a ball milling medium, and the weight ratio of balls to materials is about 3:1, and ball milled on a fast mill; the ball-milled slurry in a polyurethane ball mill tank is passed through a 60-mesh sieve, and transferred to the enamel Put it in an iron pan, place it in an electric b...

Embodiment 3

[0076] 1) Provide 30.7wt% of kaolin, 59.5wt% of barium carbonate, and 9.8wt% of alumina to obtain frit raw materials.

[0077] 2) Add 20% by weight lithium fluoride to the above-mentioned frit raw materials, mix them in a blender, put them into a platinum dry pot, and raise the temperature of the silicon-molybdenum rod lifting electric furnace to 1500°C, put the crucible Put it in, keep it warm for 1.5h, melt to obtain uniform and clear barium feldspar glass liquid, pour the glass liquid into water and quench it, beat the quenched barium feldspar glass into small pieces with a mortar and put it into a polyurethane ball mill jar In the process, water is used as a dispersant, zirconia balls are used as a ball milling medium, and the weight ratio of balls to materials is about 3:1, and ball milled on a fast mill; the ball-milled slurry in a polyurethane ball mill tank is passed through a 60-mesh sieve, and transferred to the enamel Put it in an iron pan, place it in an electric b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com