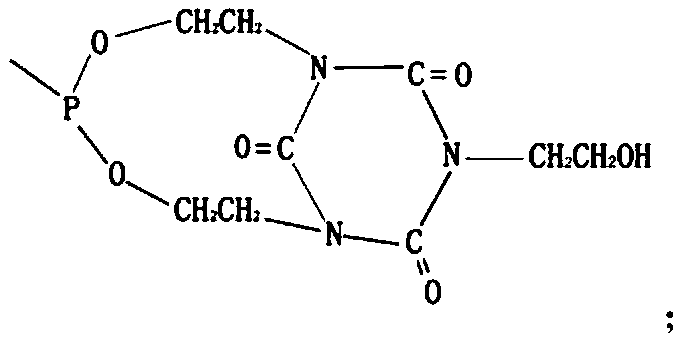

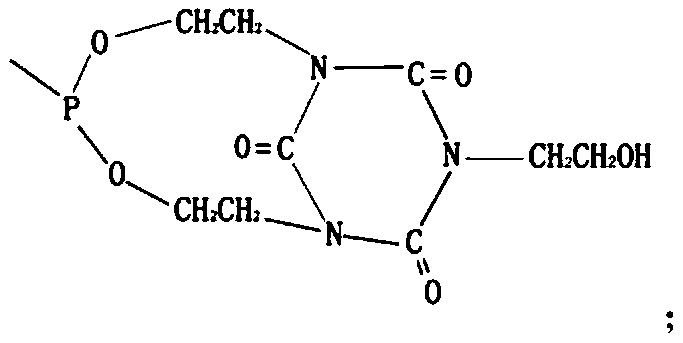

Tri(2-hydroxyethyl) isocyanurate-phosphite alcohol ester, as well as preparation method and application thereof

A technology of Cyclo phosphite and triethyl phosphite, which is applied in the field of thermal stability, can solve problems such as damage to the interests of product enterprises, polymer incompatibility, decrease in polymer volume resistivity, etc., to avoid inherent defects, Good compatibility, suitable for market promotion and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

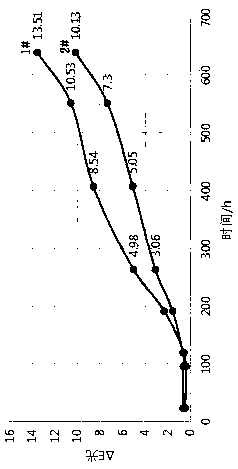

Examples

preparation example Construction

[0034] A kind of preparation method of Sike phosphite alcohol ester of the present invention comprises the following steps: Step 1, add triethyl phosphite, Sike, catalyst in the same reaction kettle, heat reaction 1-3 hour, reaction temperature is 80- At 130°C, the ethanol produced by the reaction was discharged to obtain substance A;

[0035] Step 2, adding alcohols to the reaction kettle, reacting with the phosphorus and nitrogen in the substance A to form a triazine ring structure;

[0036] Step 3: After the reaction in Step 2 is complete, the reaction kettle is heated to remove excess alcohol to obtain the finished product of Cyke phosphite alcohol ester.

[0037] Wherein, the triethyl phosphite: Saike: the mol ratio of alcohols is 1:1:X;

[0038] The alcohols are monohydric linear alcohols, and the X=1-1.2;

[0039] The alcohols are binary linear alcohols, and the X=0.5-0.7;

[0040] The alcohols are pentaerythritol, and the X=0.25-0.4.

[0041] Based on the degree of...

Embodiment 1

[0065] Example 1: Cyke lauryl phosphite

[0066] Add 277 kilograms of triethyl phosphite, 437 kilograms of saike, and 14 kilograms of phosphoric acid in the reaction kettle equipped with stirring and temperature controller, heating coil, condenser and collection bottle, and heat to 100 ° C for 1 hour. Add 341 kilograms of lauryl alcohol, heat to 150 DEG C and react for 4 hours, continue to heat up to 190 DEG C, and evaporate excess alcohol under normal pressure. The constant temperature was maintained for half an hour, and the reaction was completed. Cooled to room temperature, the product is a colorless oily liquid with a slight taste of phosphite.

Embodiment 2

[0067] Embodiment 2: Cyke stearyl phosphite

[0068] Add 277 kilograms of triethyl phosphite, 437 kilograms of Saike, and 14 kilograms of phosphoric acid in the reaction kettle equipped with stirring and temperature controller, heating coil, condenser and collection bottle, and heat to 100 ° C for 2 hours. Add 541 kilograms of stearyl alcohol, heat to 150 DEG C and react for 4 hours, continue to heat up to 190 DEG C, evaporate excess alcohol under normal pressure. The constant temperature was maintained for half an hour, and the reaction was completed. Cooled to normal temperature, the product is a white odorless solid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com