A kind of silicon oxide reinforced polyimide airgel micropowder and preparation method thereof

A technology of polyimide and airgel, which is applied in the field of online polyimide airgel micropowder and its preparation, can solve the problems of high cost, poor lightness, and low strength, and achieve low cost and functional group Numerous, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A preparation method of linear polyimide airgel micropowder reinforced by silicon oxide, comprising the following steps:

[0027] Step (1), methyl vinyl ether-maleic anhydride copolymer, 3-aminopropyltriethoxysilane and aromatic diamine are dissolved in solvent respectively to obtain methyl vinyl ether-maleic anhydride copolymer solution, 3-aminopropyltriethoxysilane solution and aromatic diamine solution;

[0028] Step (2), the methyl vinyl ether-maleic anhydride copolymer solution, the 3-aminopropyltriethoxysilane solution and the aromatic diamine solution are stirred and mixed in a certain proportion and left to stand to form a gel, Then soak the formed gel in a dehydrating agent for chemical imidization to obtain an imidized gel;

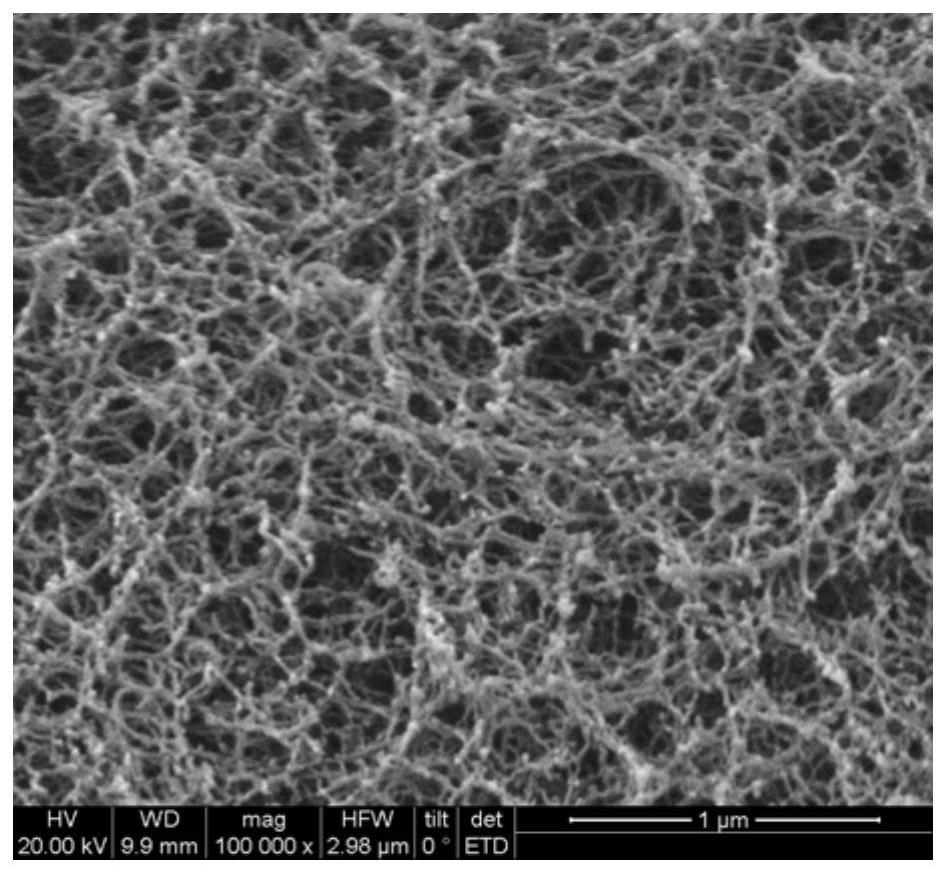

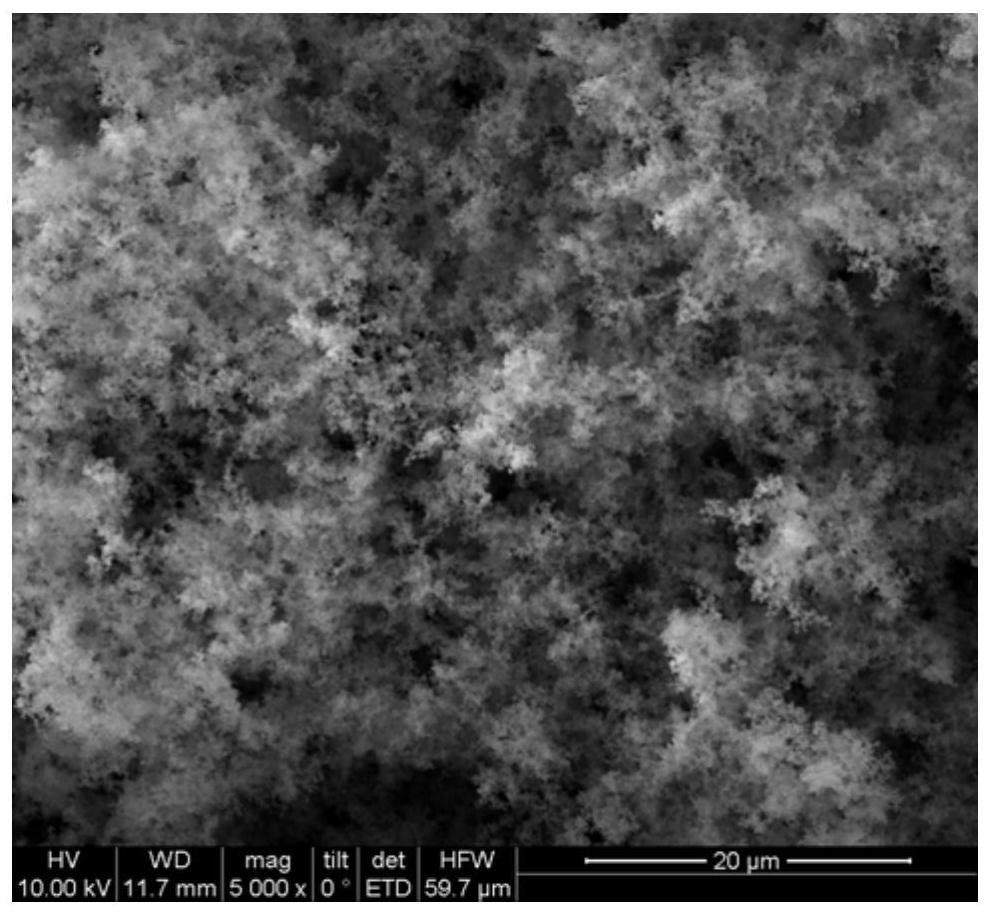

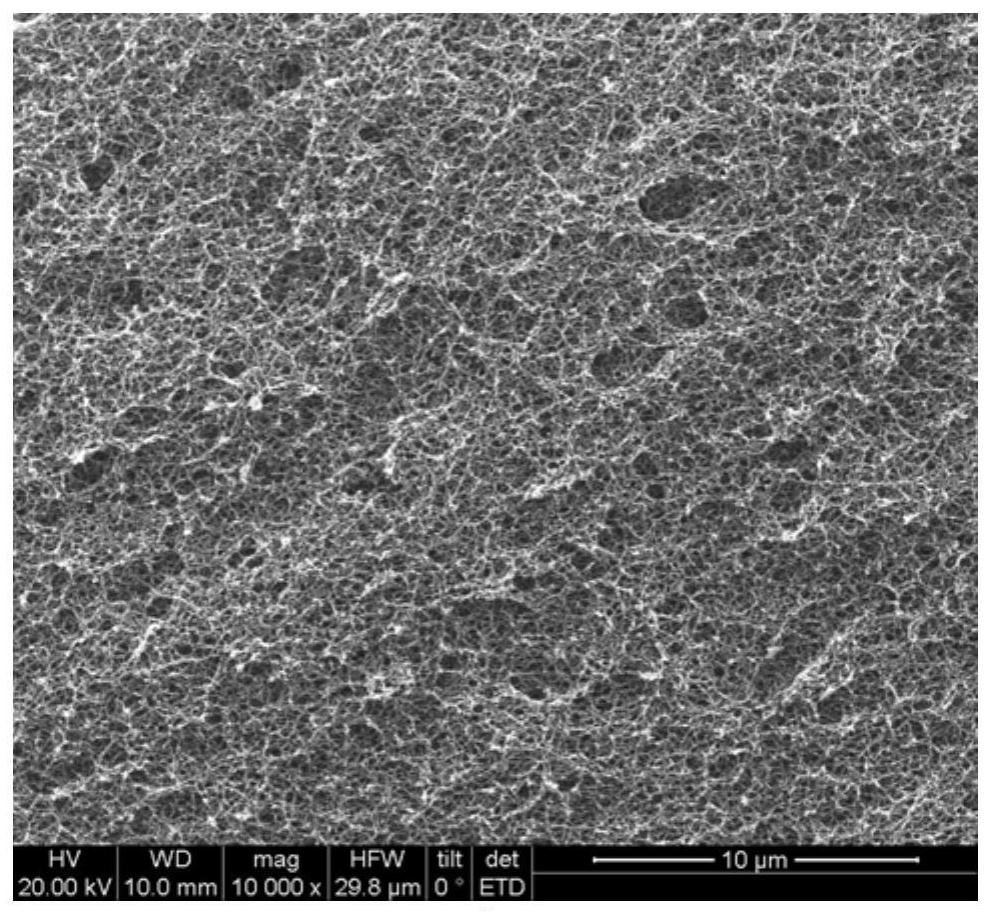

[0029] In step (3), the imidized gel is pulverized, solvent replaced, and dried to obtain a linear polyimide airgel micropowder reinforced with silicon oxide nanoparticles.

[0030] Among them, the aromatic diamine described in step (1)...

Embodiment 1

[0039] (1) Configuration of the monomer solution: take 10g of methyl vinyl ether-maleic anhydride copolymer, 1g of 3-aminopropyltriethoxysilane, and 5g of p-phenylenediamine, and dissolve them in 100ml of N-methyl In base pyrrolidone, it is configured to have a concentration of 0.1, 0.01, 0.05g / cm 3 The solution.

[0040] (2) Synthesis of gel: Take 100, 5 and 30ml of the above solutions respectively, mix them evenly, form a gel at 0°C, then soak the gel in a mixed solution of pyridine and acetic anhydride (volume ratio 1:1) for dehydration .

[0041] (3) Preparation of polyimide airgel micropowder—grinding, solvent replacement and drying: the dehydrated gel (imidized gel) was first squeezed at 30°C for 3 hours under a pressure of 2 MPa, and then Stir at a speed of 1000 rpm for 3 hours to obtain wet gel micropowder, and then soak in 2 times the volume of methanol for solvent replacement. The methanol is replaced every 5 hours for a total of 3 replacements. The replaced gel w...

Embodiment 2

[0043] (1) Configuration of monomer solution: Take 30g of methyl vinyl ether-maleic anhydride copolymer, 5g of 3-aminopropyltriethoxysilane, and 20g of p-phenylenediamine, and dissolve them in 100ml N, N -In dimethylacetamide, configure the concentration to be 0.3, 0.05, 0.2g / cm 3 The solution.

[0044] (2) Synthesis of gel: Take 100, 5 and 30ml of the above solutions respectively, mix them evenly, form a gel at 40°C, and then soak the gel in a mixed solution of triethylamine and acetic anhydride (volume ratio 1:1) Medium dehydration.

[0045] (3) Preparation of polyimide airgel micropowder - pulverization, solvent replacement and drying: first extrude the above-mentioned dehydrated gel at 50°C and 3MPa pressure for 1 hour, and then stir at a speed of 2000 rpm After 2 hours, the wet gel micropowder was obtained, and then soaked in 2 times the volume of ethanol for solvent replacement. The ethanol was changed every 10 hours for a total of 3 times. The replaced gel was dried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com