Water-based intermediate paint and preparation method thereof

A kind of intermediate paint, water-based technology, applied in the field of coatings, can solve the problems of abrasion resistance, impact resistance, flexibility, adhesion and anti-sag performance, etc., achieve good anti-sag performance, good stability, and increase hardness and the effect of abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

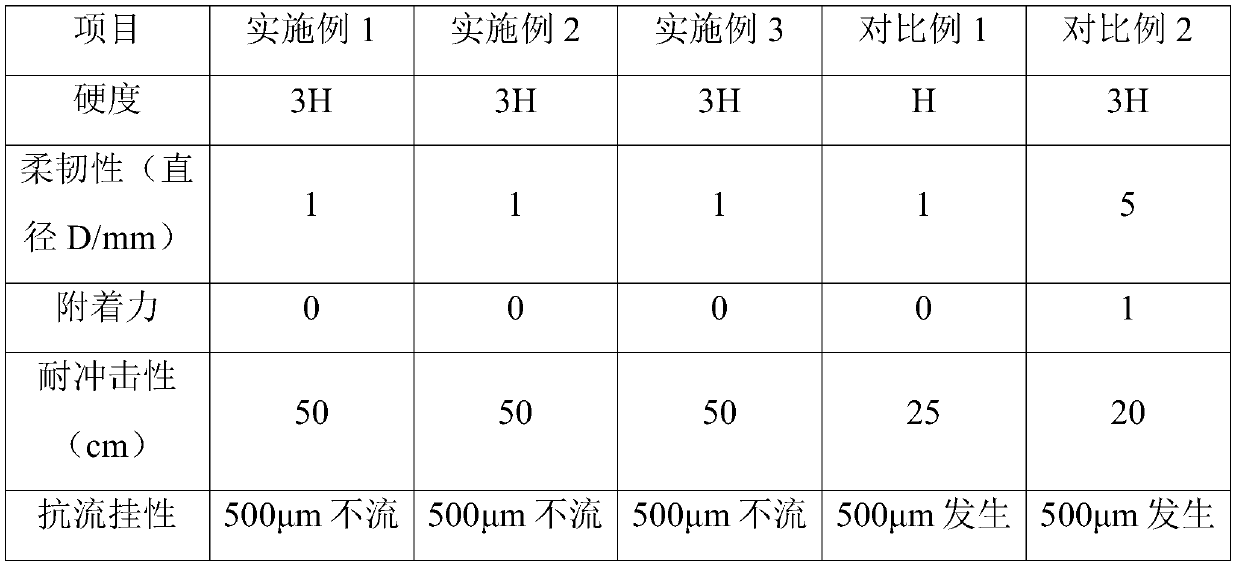

Examples

Embodiment 1

[0033] A water-based intermediate paint, comprising A component and B component;

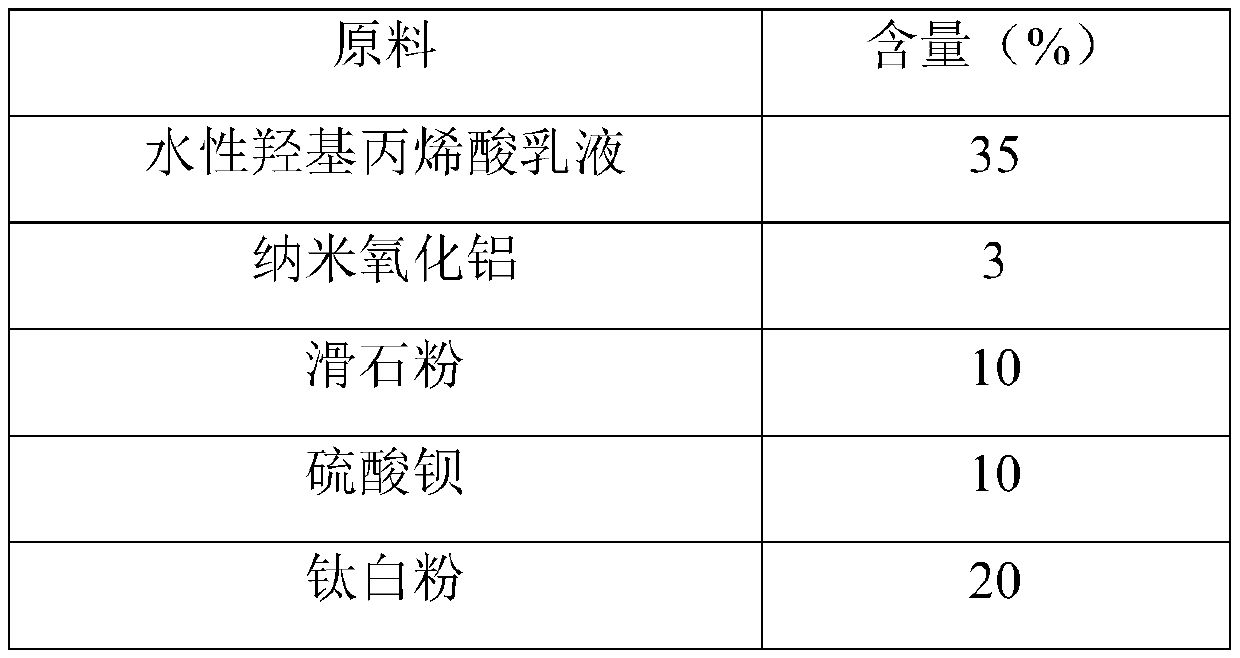

[0034] Described A component comprises the component of following mass percentage:

[0035] raw material content(%) Waterborne Hydroxy Acrylic Emulsion 25 Nano alumina 5 talcum powder 20 Barium sulfate 20 Titanium dioxide 10 Graphene oxide 0.2 Lithium magnesium silicate 0.1 Dimethylethanolamine 0.1 Defoamer 0.1 Coalescent 2 Dispersant 0.3 Substrate wetting agent 0.3 thickener 0.5 Deionized water 16.4

[0036] Described B component comprises the component of following mass percentage:

[0037] raw material content(%) Hydrophilic modified aliphatic polyisocyanate 60 Propylene glycol methyl ether acetate 40

[0038] The mass ratio of component A to component B in the water-based intermediate paint is 4:1.

[0039] Among them, the water-based hydroxyacrylic acid emulsion is...

Embodiment 2

[0046] A water-based intermediate paint, comprising A component and B component;

[0047] Described A component comprises the component of following mass percentage:

[0048] raw material content(%) Waterborne Hydroxy Acrylic Emulsion 50 Nano alumina 1 talcum powder 5 Barium sulfate 5 Titanium dioxide 25 Graphene oxide 1 Lithium magnesium silicate 0.5 Dimethylethanolamine 0.2 Defoamer 0.2 Coalescent 5 Dispersant 0.5 Substrate wetting agent 0.6 thickener 1 Deionized water 5

[0049] Described B component comprises the component of following mass percentage:

[0050] raw material content(%) Hydrophilic modified aliphatic polyisocyanate 80 Propylene glycol methyl ether acetate 20

[0051] The mass ratio of component A to component B in the water-based intermediate paint is 4:1.

[0052] Among them, the water-based hydroxyacrylic acid emulsion is Bayhydro...

Embodiment 3

[0059] A water-based intermediate paint, comprising A component and B component;

[0060] Described A component comprises the component of following mass percentage:

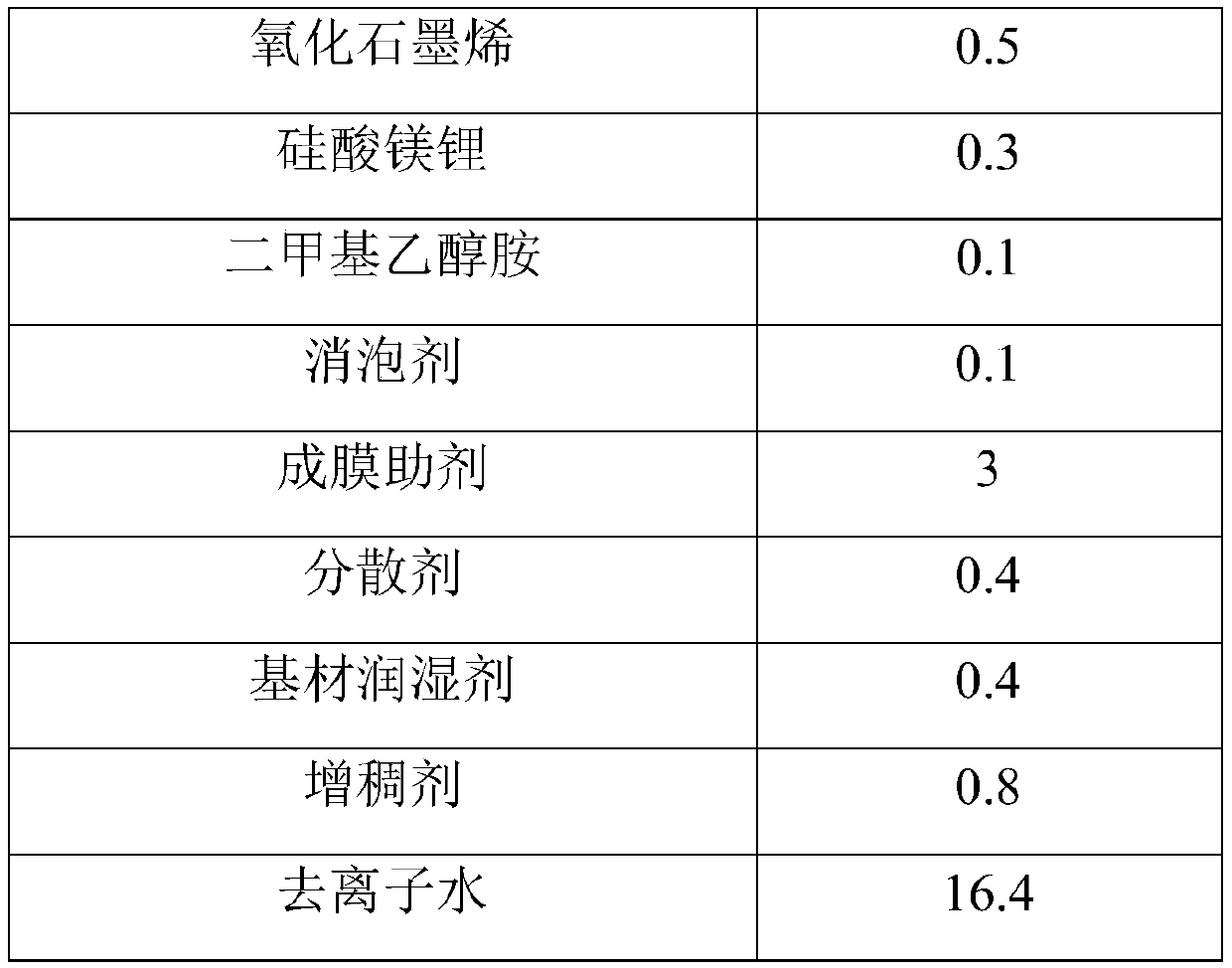

[0061]

[0062]

[0063] Described B component comprises the component of following mass percentage:

[0064] raw material content(%) Hydrophilic modified aliphatic polyisocyanate 70 Propylene glycol methyl ether acetate 30

[0065] The mass ratio of component A to component B in the water-based intermediate paint is 5:1.

[0066] Wherein, the water-based hydroxyacrylic acid emulsion selects Bayhydrol A 2695 of Bayer; the particle diameter of talcum powder is 1250 mesh; the particle diameter of barium sulfate is 1500 mesh; Foaming agent (941PL from MOUSSEX company) and silicone defoamer (BYK-028 from BAK company); film-forming aid is composed of dipropylene glycol methyl ether and alcohol ester-12 with a mass ratio of 1:2; dispersion TEGO dispersers 760W is selected as the age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com