Preparation method of room-temperature cured high-temperature-resistant organic silicon adhesive

A room temperature curing, silicone adhesive technology, applied in the preparation of silicone adhesives, high temperature and aging resistant room temperature curing silicone adhesives, can solve the problem of heat resistance decline, sealant hardness, mechanical properties and adhesive performance decline, The colloid loses its elasticity and bonding ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

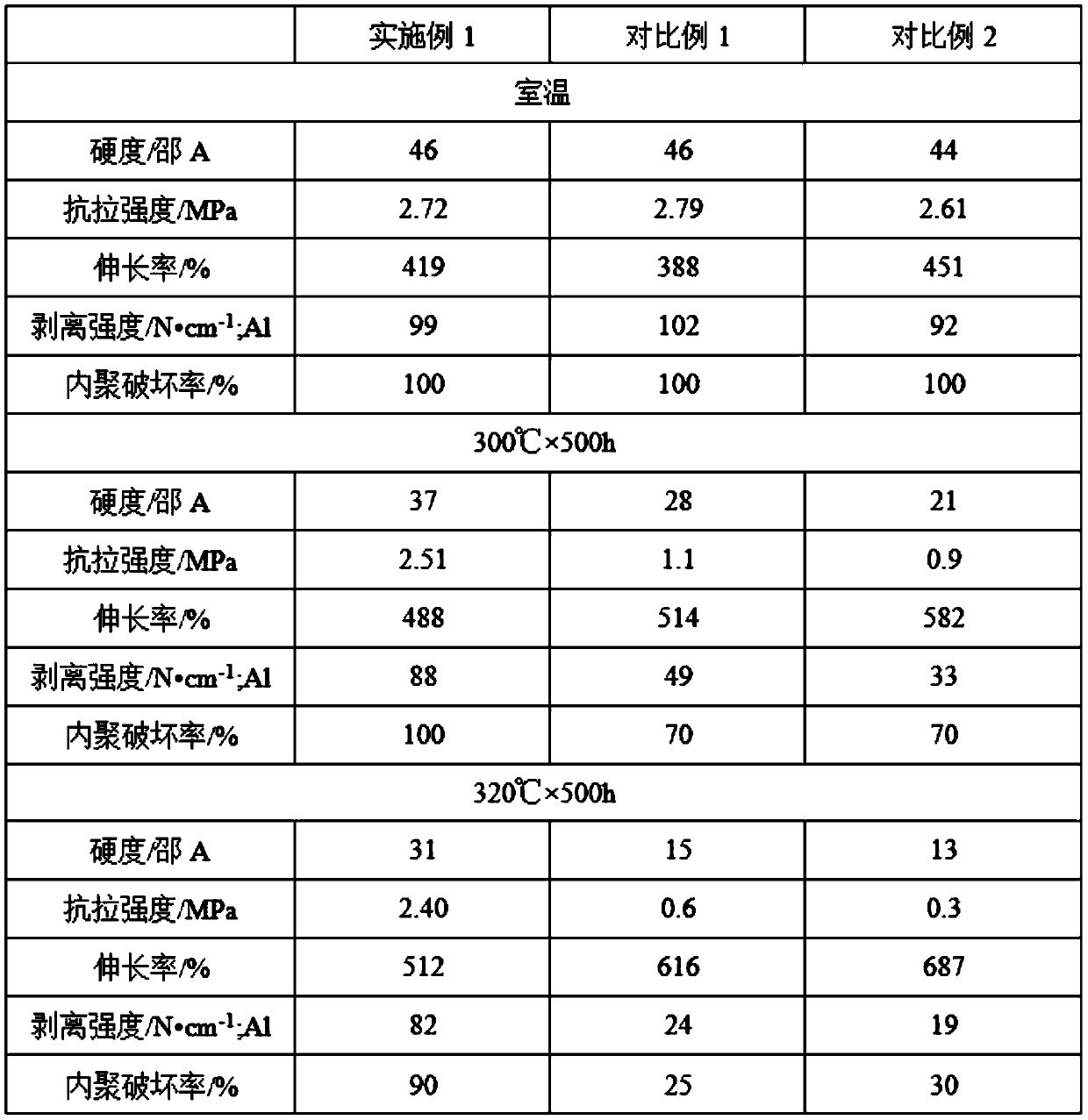

Examples

Embodiment 1

[0030] The preparation method provided in this example is as follows: pour 50 g of ferrocene lithium salt into a beaker, add 100 mL of toluene, stir to dissolve and set aside. Add 100 g of a mixture of methyltrichlorosilane and methyltrimethoxysilane, 100 mL of methanol into the flask, turn on nitrogen and stir. At room temperature, the toluene solution of the completely dissolved lithium ferrocene salt was dropped into the flask, and the dropping time was controlled to be 1 h. After the dropwise addition, react at room temperature for 3 h, and filter off the residue. Add 100mL of toluene and 35mL of pure water into the flask, mix the resulting product solution with 120g of a mixture of methyltrichlorosilane and methyltrimethoxysilane, and 50mL of methanol, and slowly drop it into the flask, controlling the dropping time for 3h. After the dropwise addition, the temperature was raised to 90°C, condensed and refluxed for 5 hours, cooled to room temperature, and the water layer ...

Embodiment 2

[0033] The preparation method provided in this example is as follows: pour 80 g of ferrocene chloride into a beaker, add 80 mL of toluene, stir to dissolve and set aside. Add 80 g of a mixture of dimethyldichlorosilane and trimethoxysilane, 80 mL of methanol to the flask, turn on nitrogen and stir. At room temperature, the toluene solution of the completely dissolved ferrocene chloride was dropped into the flask, and the dropping time was controlled to be 1 h. After the dropwise addition, react at room temperature for 5 h, and filter off the residue. Add 80mL of toluene and 30mL of pure water into the flask, mix the resulting product solution with 110g of a mixture of dimethyldichlorosilane and dimethyldimethoxysilane, and 50mL of methanol, and slowly drop them into the flask, controlling the dropping time for 3h . After the dropwise addition, raise the temperature to 90°C, condense and reflux for 6 hours, cool to room temperature, separate the water layer, neutralize the oi...

Embodiment 3

[0036] The preparation method provided in this example is as follows: pour 60 g of ferrocene ethanol into a beaker, add 100 mL of toluene, stir to dissolve and set aside. Add 100 g of tetrachlorosilane and methyl orthosilicate mixture, 100 mL of methanol into the flask, turn on nitrogen and stir. At room temperature, the completely dissolved ferrocene ethanol solution in toluene was dropped into the flask, and the dropping time was controlled to be 1 h. After the dropwise addition, react at room temperature for 8 h, and filter off the residue. Add 100mL of toluene and 35mL of pure water into the flask, mix the obtained product solution with 120g of tetrachlorosilane and methyl orthosilicate mixture, and 50mL of methanol, slowly drop into the flask, and control the dropping time for 3h. After the dropwise addition, raise the temperature to 90°C and reflux for 8 hours, cool to room temperature, separate the water layer, neutralize the oil layer with 10g of ammonium bicarbonate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com