Preparation method of graphene-rare earth up-conversion composite material and application thereof in joint toxicity evaluation of pesticides

A rare earth upconversion and composite material technology, applied in the application of pesticide combined toxicity evaluation, in the field of preparation of graphene-rare earth upconversion composite material, which can solve the problem of low upconversion luminous efficiency, poor water solubility, few functional groups, etc. problem, to achieve the effect of stable photochemical properties, low toxicity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

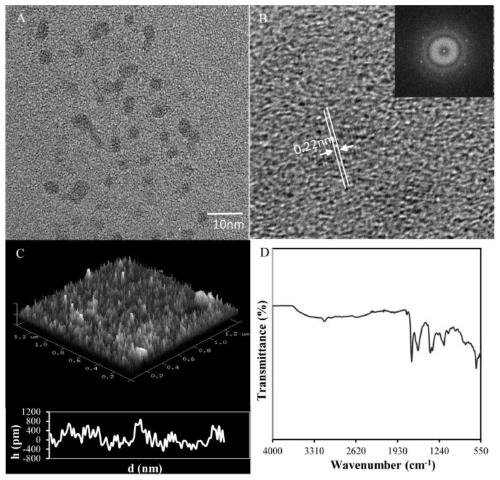

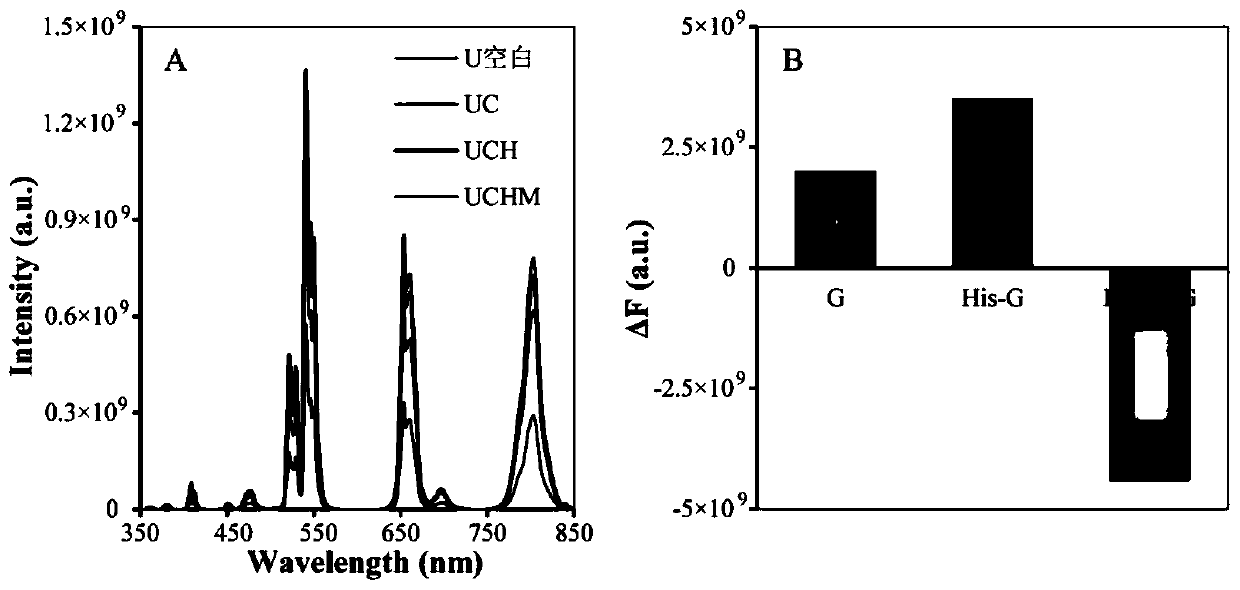

[0039] (1) Take citric acid monohydrate, histidine and M in a beaker, wherein the mol ratio of citric acid monohydrate and histidine is 1:0.1, and the mass ratio of citric acid monohydrate and M is 1:0.05, Add 5ml of water and put it in a constant temperature blast drying oven at 150°C for 6h to prepare His-M-GQD;

[0040] Weigh citric acid monohydrate and histidine at a molar ratio of 1:0.1, add 5ml of water, and place in a constant temperature blast drying oven at 150°C for 6 hours to prepare His-GQD;

[0041] Weigh 0.1g of citric acid monohydrate and add it to 5ml of water, put it into a constant temperature blast drying oven at 150°C for 5h to prepare graphene quantum dots GQD;

[0042] Prepare His-M-GQD, His-GQD and GQD respectively into 25 mg / ml aqueous solution, and adjust the pH to neutral; since dimethyl biguanide hydrochloride is unstable in the presence of strong alkali, use PBS buffer solution to adjust pH of the His-M-GQD solution;

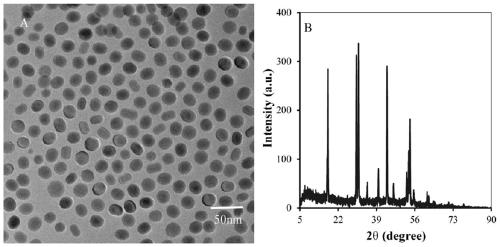

[0043] (2) UCNP coated with ...

Embodiment 2

[0050] (1) Take citric acid monohydrate, histidine and M in a beaker, wherein the mol ratio of citric acid monohydrate and histidine is 1:1, and the mass ratio of citric acid monohydrate and M is 1:0.3, Add 25ml of water and put it into a 2000°C constant temperature blast drying oven for 10h to prepare His-M-GQD;

[0051] Weigh citric acid monohydrate and histidine at a molar ratio of 1:1, add 25ml of water, and place in a constant temperature blast drying oven at 180°C for 10 hours to prepare His-GQD;

[0052] Weigh 10g of citric acid monohydrate and add it to 30ml of water, put it into a 2100°C constant temperature blast drying oven for 10h to prepare graphene quantum dots GQD;

[0053] Prepare His-M-GQD, His-GQD and GQD respectively into 60mg / ml aqueous solution, and adjust the pH to neutral; since dimethyl biguanide hydrochloride is unstable in the presence of strong alkali, use PBS buffer solution to adjust pH of the His-M-GQD solution;

[0054] (2) UCNP coated with ole...

Embodiment 3

[0061] (1) Take citric acid monohydrate, histidine and M in a beaker, wherein the mol ratio of citric acid monohydrate and histidine is 1:10, and the mass ratio of citric acid monohydrate and M is 1:0.5, Add 50ml of water and put it into a 250°C constant temperature blast drying oven for 0.5h to prepare His-M-GQD;

[0062] Weigh citric acid monohydrate and histidine at a molar ratio of 1:10, add 50ml of water, and place in a constant temperature blast drying oven at 250°C for 0.5h to prepare His-GQD;

[0063] Weigh 100g of citric acid monohydrate and add it to 5ml of water, and put it into a 250°C constant temperature blast drying oven for 0.5h to prepare graphene quantum dots GQD;

[0064] Make His-M-GQD, His-GQD and GQD into 100mg / ml aqueous solution, adjust the pH to neutral; since dimethyl biguanide hydrochloride is unstable in the presence of strong alkali, use PBS buffer solution to adjust pH of the His-M-GQD solution;

[0065] (2) UCNP coated with oleic acid was prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com