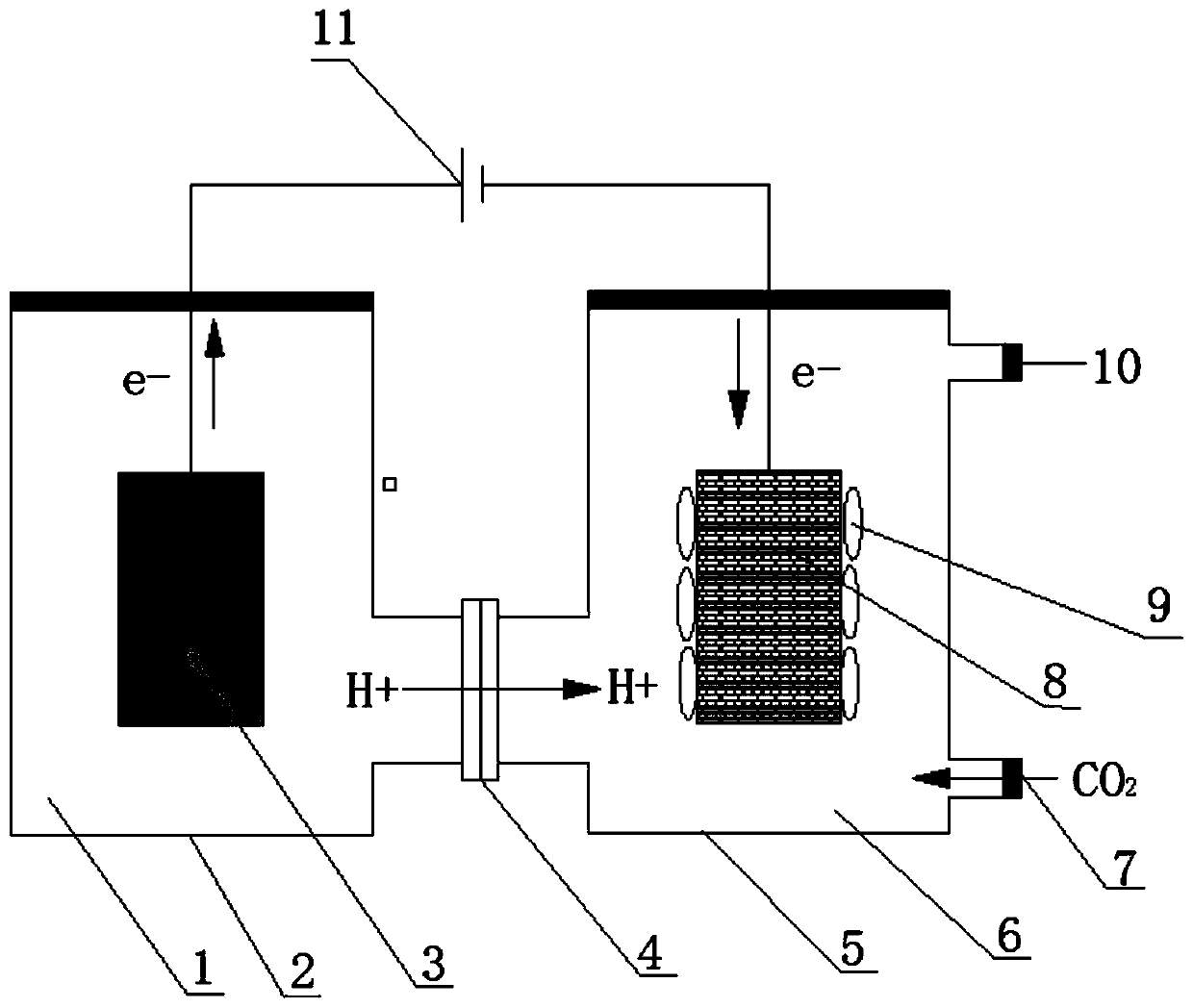

Method for synthesizing organic matter by catalytically reducing CO2 through MES biological cathode

A bio-cathode, microbial electrosynthesis technology, applied in the direction of electrolytic organic production, chemical/physical/physical-chemical processes of energy application, cells, etc., can solve the problems of requiring precious metal catalysts, high cost, high energy consumption, and achieve CO2 resource utilization problem solving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] Preparation of anolyte and catholyte: anode chamber electrolyte: KH 2 PO 4 6.8g / L, NaOH 0.944g / L to adjust the pH of the electrolyte in the anode compartment to 6.0. Cathode chamber culture solution: K 2 HPO 4 2.18g / L, KH 2 PO 4 1.70g / L, NaHCO 3 2.50g / L, NH 4 Cl1.25g / L, KCl0.10g / L, MgCl 2 ·6H 2 O 1.00g / L, NaCl 0.80g / L, CaCl 2 2H 2 O 0.30g / L, L-cysteine 0.50g / L, trace element solution 10ml / L, vitamin solution 10ml / L, adjust the catholyte pH to 6.0.

[0016] Operation of the bioelectrochemical reactor: before the activated sludge is put into the reactor, it is placed in a dry place for anaerobic exposure to remove undesirable bacteria such as mold. Get 20mL of activated sludge and access the electrochemical reactor cathode, add 480mL liquid culture medium simultaneously, add the phosphate buffer (pH=6.0) of 500mL in the anode electrolysis chamber, by adding methane inhibitor (2- Sodium bromoethylsulfonate) to inhibit the activity of methanogens in sludge...

example 1

[0021] Example 1: In the microbial electrosynthesis system of the present invention, when the temperature of the cathode chamber of MES is controlled at 37°C and the cathode potential is controlled at -0.7Vvs.Ag / AgCl, the final accumulation of formic acid after 24h is 1.554mmol / L, The final accumulation of acetic acid was 2.754mmol / L.

example 2

[0022] Example 2: In the microbial electrosynthesis system of the present invention, when the temperature of the cathode chamber of MES is controlled at 37°C and the cathode potential is controlled at -0.8Vvs.Ag / AgCl, the final accumulation of formic acid after 24h is 1.467mmol / L, The final accumulation of acetic acid was 2.608mmol / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com