Flexible tactile sensor and preparation method and application thereof

A tactile sensor and flexible technology, applied in the field of sensors, can solve the problems of unstable nature, complex preparation process, and biological safety, etc., and achieve the effects of high-sensitivity tactile perception, simple system structure, and low pressure detection limit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

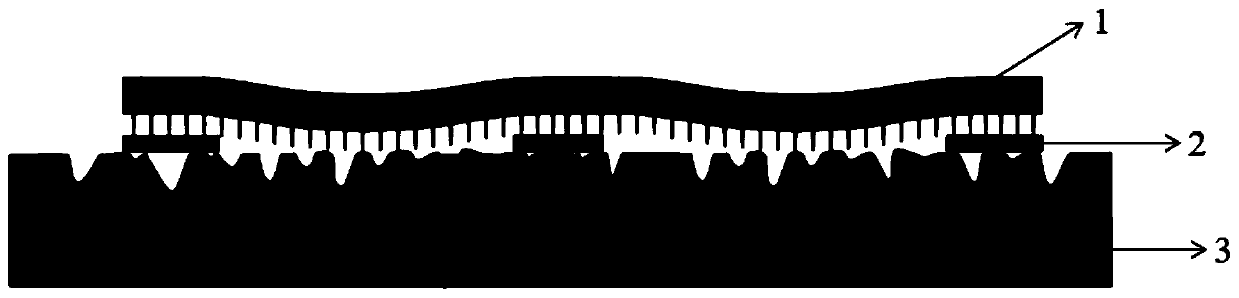

[0066] A flexible tactile sensor such as figure 1 As shown, it consists of a flexible electrode with a micro-nano structure and a flexible gasket layer, and the side of the flexible electrode with the micro-nano structure is attached to the flexible gasket layer.

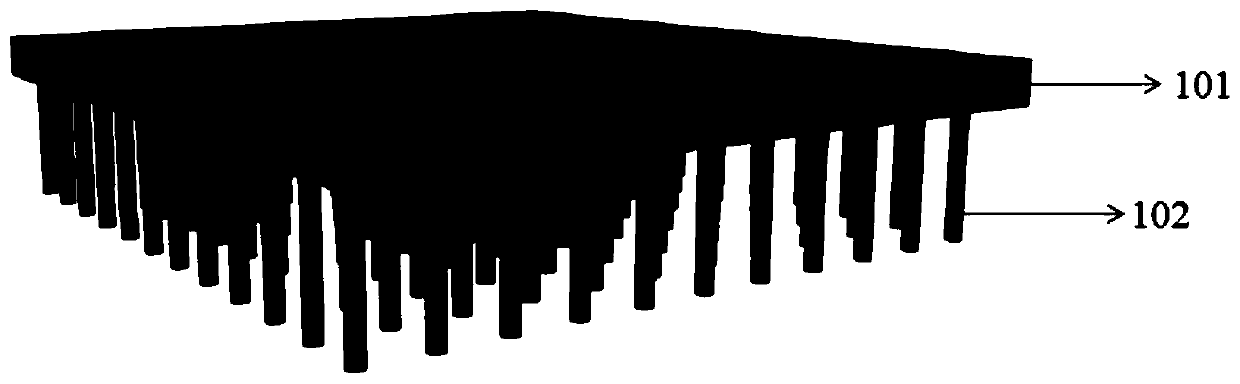

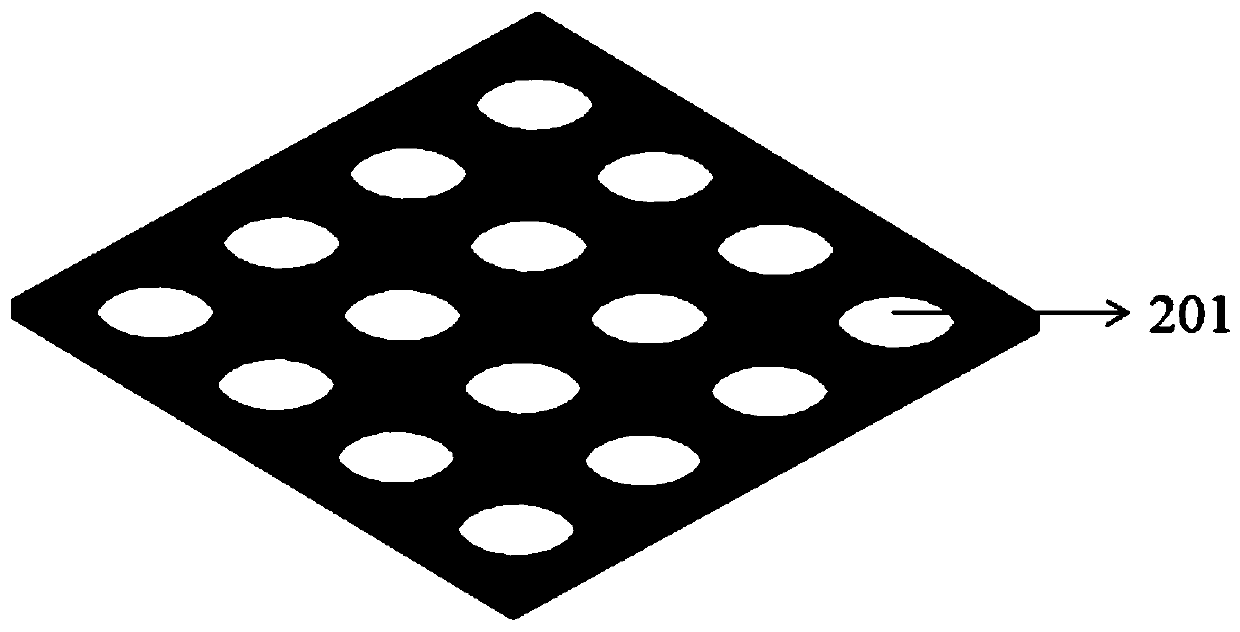

[0067] like figure 2 As shown, the flexible electrode has a micro-nano structure array, and the micro-nano structure is a high-diameter ratio micro-column; as image 3 As shown, the flexible spacer layer has a circular through-hole. It should be noted that the size in the figure may not represent the actual size, and is only for illustration.

[0068] The preparation method is as follows:

[0069] (1) Using photolithography technology, etch a circular hole structure with a high-diameter ratio on the silicon plate as a primary template. The diameter of the microhole is 5 μm, the depth is 10 μm, and the center distance of the microhole is 15 μm; use hot pressing Printing technology, using polycarbonate polymer fi...

Embodiment 2

[0076] A flexible tactile sensor is composed of a flexible electrode with a micro-nano structure and a flexible pad layer, and the side of the flexible electrode with the micro-nano structure is attached to the flexible pad layer.

[0077] The flexible electrode has a micro-nano structure array, and the micro-nano structure is a high-diameter ratio micro-column; the flexible gasket layer has a circular through hole.

[0078] The preparation method is as follows:

[0079] (1) Using photolithography technology, etch a circular hole structure with a high-diameter ratio on the silicon plate as a primary template. The diameter of the microhole is 15 μm, the depth is 50 μm, and the center distance of the microhole is 40 μm; use hot pressing Printing technology, using polycarbonate polymer film as the transfer material, using the primary template as the template, and preparing a secondary template with a micro-column structure by transfer printing;

[0080] (2) Using ion gel as raw ...

Embodiment 3

[0086] A flexible tactile sensor is composed of a flexible electrode with a micro-nano structure and a flexible pad layer, and the side of the flexible electrode with the micro-nano structure is attached to the flexible pad layer.

[0087] The flexible electrode has a micro-nano structure array, and the micro-nano structure is a high-diameter ratio micro-column; the flexible gasket layer has a circular through hole.

[0088] The preparation method is as follows:

[0089] (1) Using photolithography technology, etch a circular hole structure with a high-diameter ratio on the silicon plate as a primary template. The diameter of the microhole is 20 μm, the depth is 30 μm, and the center distance of the microhole is 50 μm; use hot pressing Printing technology, using polycarbonate polymer film as the transfer material, using the primary template as the template, and preparing a secondary template with a micro-column structure by transfer printing;

[0090] (2) Using polydimethylsil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com