Positive electrode material, positive electrode pole piece prepared from the same and obtained lithium ion battery

A lithium-ion battery, cathode material technology, applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve problems such as poor safety and cycle performance, achieve high rate performance, maintain integrity, and reduce stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

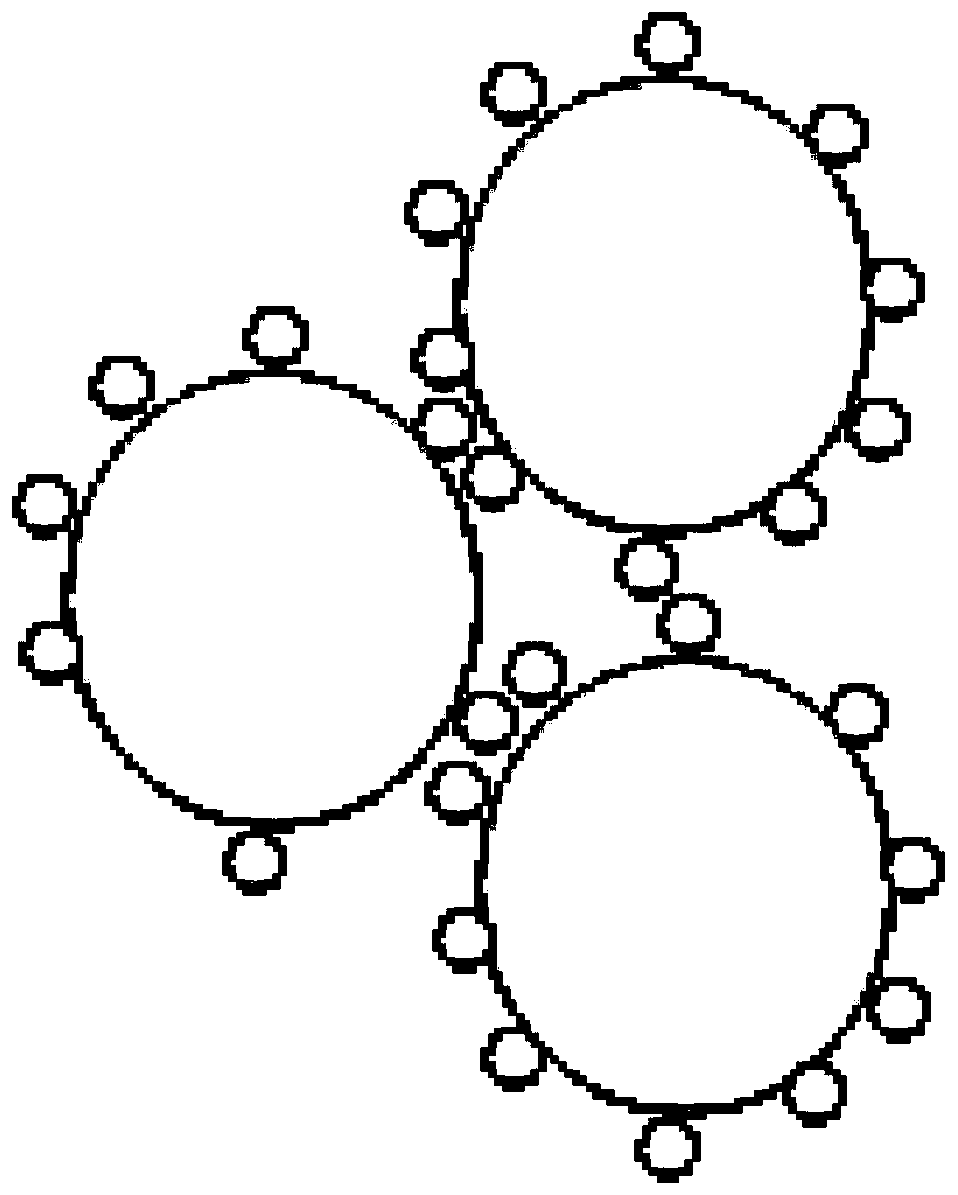

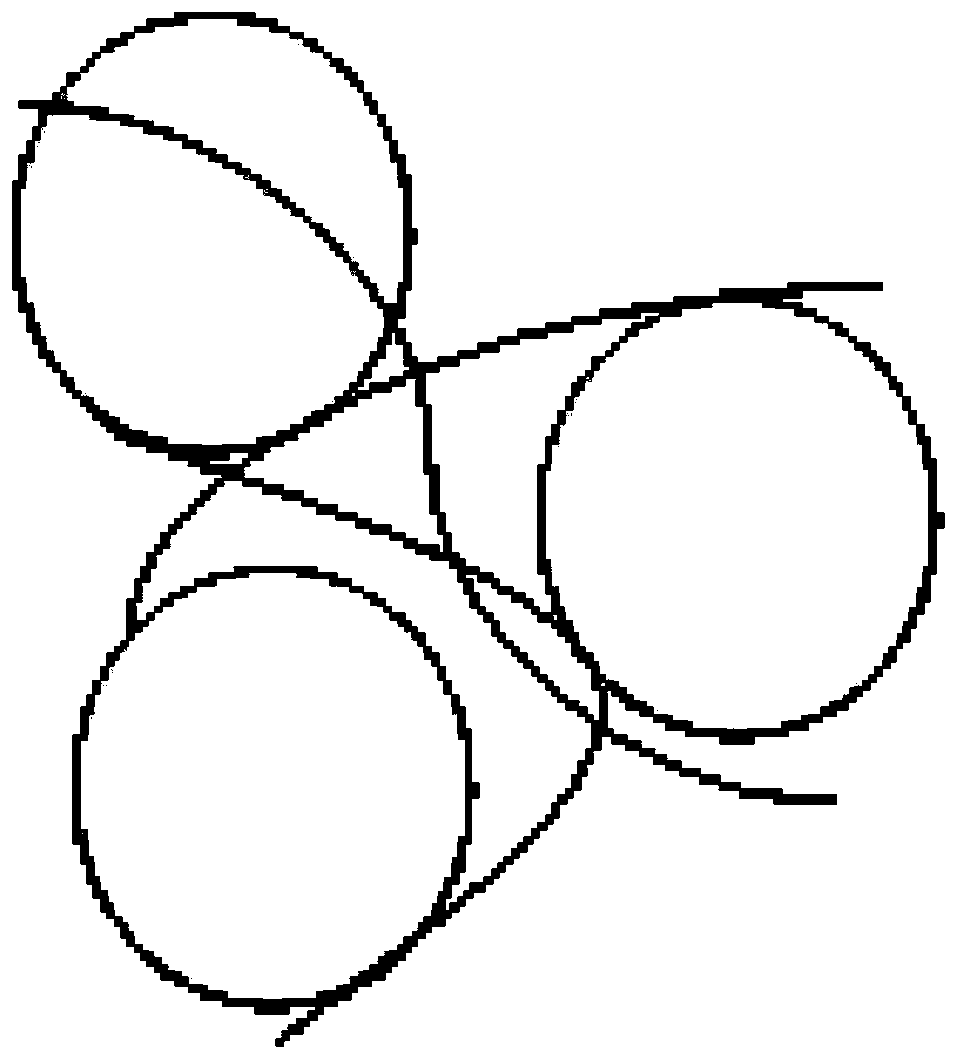

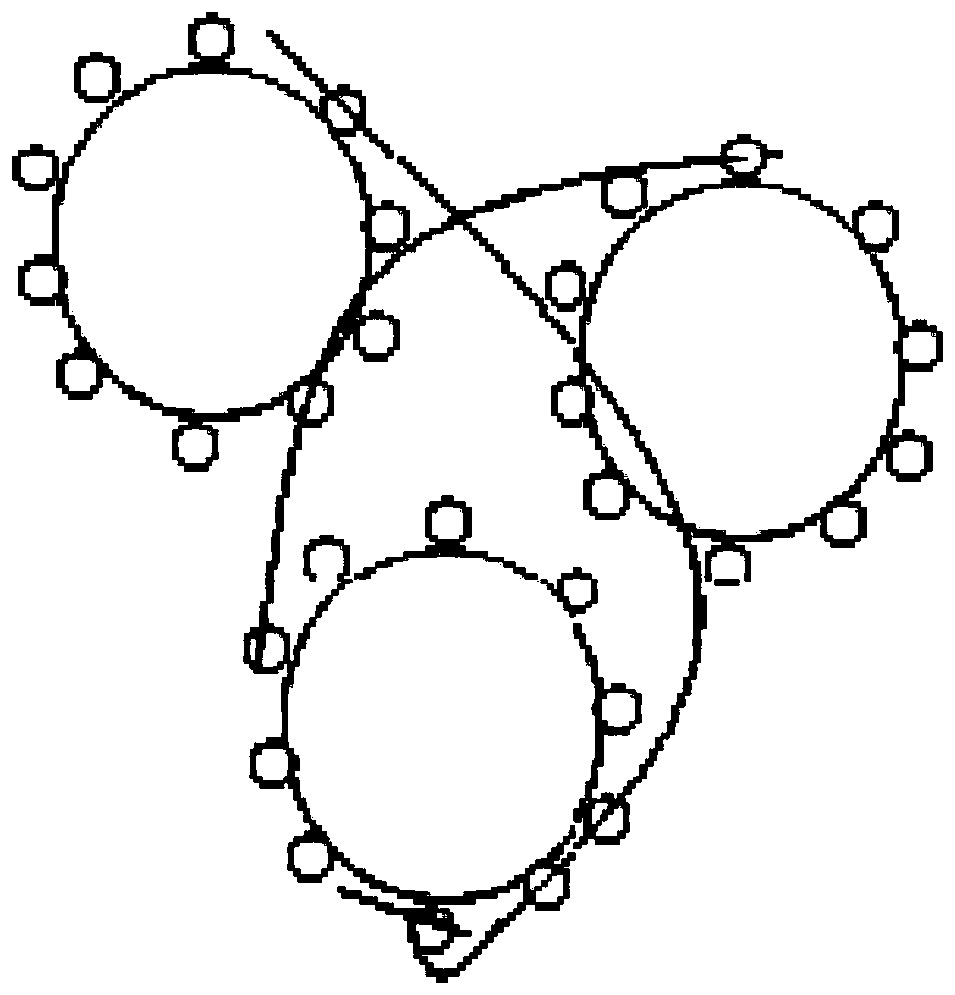

Image

Examples

Embodiment 1

[0087] (1) Preparation of modified superconducting carbon black: Superconducting carbon black (Cabot LTIX300) with a particle size of 50nm and elemental red phosphorus with a particle size of 8nm are carried out at a mass ratio of 1:3 at a speed of 300r / min The ball mill was mixed for 12 hours, sieved with 300 mesh, and heat-treated at 350°C for 9.5 hours to obtain modified superconducting carbon black;

[0088] (2) Positive electrode sheet preparation: LiNi with a mass content of 96% 0.6 co 0.2 mn 0.2 o 2 , 1.8% modified superconducting carbon black, 1.2% carbon nanotubes and 1.0% polyvinylidene fluoride are mixed with NMP, coated on the surface of aluminum foil, dried at 120°C, and rolled to obtain an areal density of 100g / m 2 positive pole piece;

[0089] (3) Negative electrode sheet preparation: Dissolve graphite, SP, dispersant (CMC), and binder (SBR) in deionized water according to the ratio of 95:2:1.5:1.5, and stir for 10 hours to make them uniformly dispersed. Co...

Embodiment 2

[0092] (1) Preparation of modified superconducting carbon black: Superconducting carbon black (Cabot LTIX300) with a particle size of 30nm and elemental red phosphorus with a particle size of 4nm are carried out at a mass ratio of 1:3.2 at a speed of 500r / min The ball mill was mixed for 8 hours, sieved with 600 mesh, and heat-treated at 600°C for 9 hours to obtain modified superconducting carbon black;

[0093] (2) Positive electrode sheet preparation: LiNi with a mass content of 94% 0.6 co 0.2 mn 0.2 o 2 , 1.5% modified superconducting carbon black, 3% carbon nanotubes and 1.5% binder mixed, coated on the surface of aluminum foil, dried at 80°C, and rolled to obtain an areal density of 80g / m 2 positive pole piece;

[0094] (3) Preparation of lithium-ion battery: 20 positive electrode sheets, 21 sheets of which are 50g / m 2 Negative electrode pole piece, electrolyte and porosity of 43% dry-process diaphragm packaging, 46 ℃ for 20h, to obtain lithium-ion batteries, ethylene...

Embodiment 3

[0097] The difference from Example 1 is that the heat treatment temperature in step (1) is 300°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Oil absorption value | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com