Application of Modified Crop Straw to Adsorption of Low Concentration Oily Sewage

A crop straw, low-concentration technology, applied in water/sewage treatment, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc., to achieve good adsorption, good adsorption, and improve adsorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

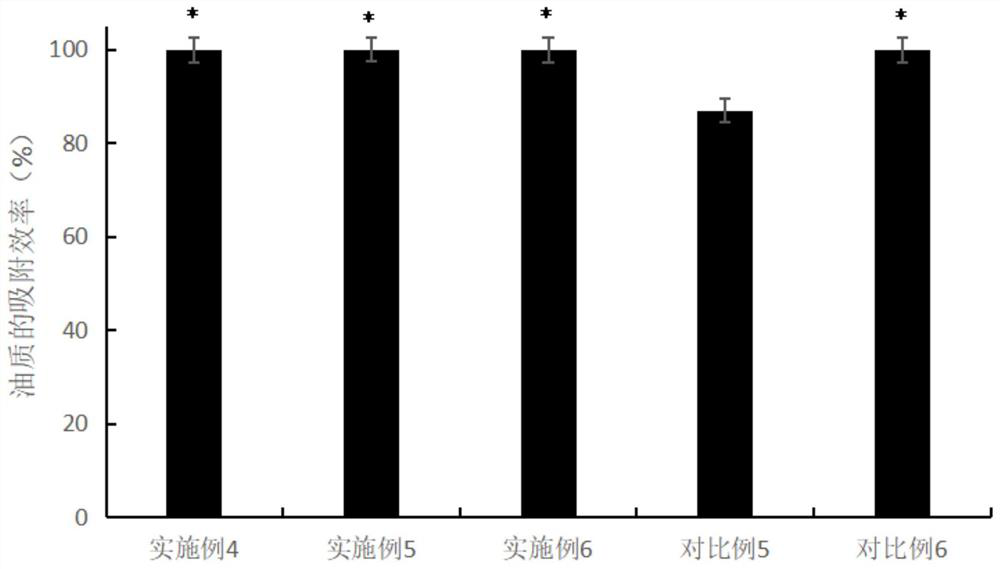

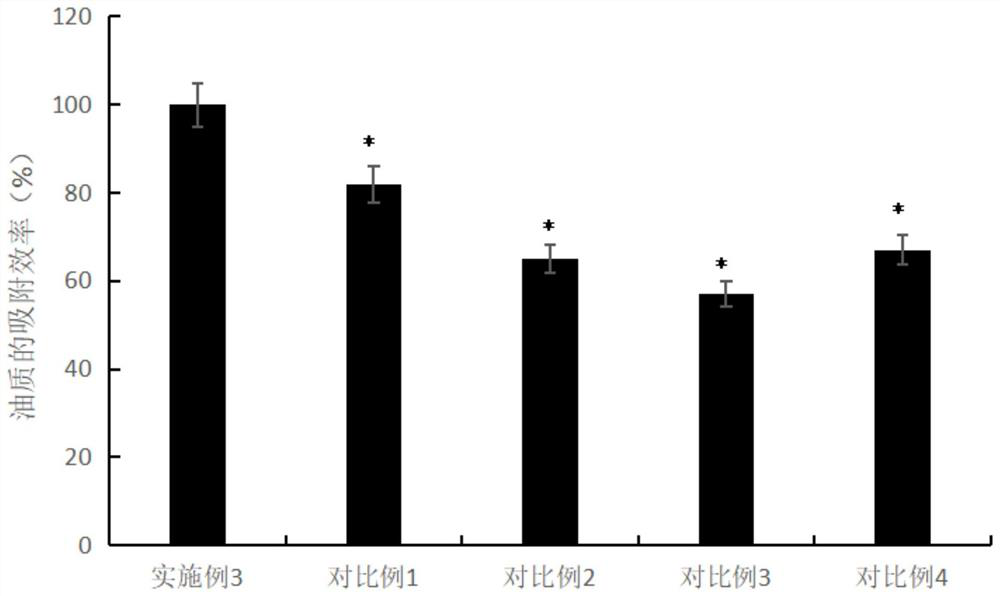

Examples

Embodiment 1

[0033] A method for preparing modified crop straw, which is prepared by the following method:

[0034] S1. Removing surface wax: pulverize the rice straw sample with a pulverizer, soak in 1-2mol / L NaOH solution for 20-24h, wash with distilled water until neutral, and dry at 50-60°C;

[0035] S2. Hydrogen bond activation: use 50wt% H 3 PO 4 Soak in the solution for 20-24 hours, wash with distilled water until neutral, and dry at 50-60°C;

[0036] S3. Preparation of sodium cellulose: adding the activated straw powder into a 10-15mol / L NaOH solution, stirring and reacting for 2-4h, filtering and drying to obtain sodium cellulose;

[0037] S4. Modification: add long-chain monohalogenated alkanes to organic solvents, add cellulose sodium, react for 3-5 hours, filter, wash with distilled water, evenly spray 5wt% triethylamine, and dry at 50-60°C to obtain Modified cellulose;

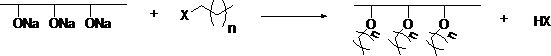

[0038] Long-chain monohalogenated alkanes have the structure of formula I:

[0039]

[0040] Formul...

Embodiment 2

[0046] A method for preparing modified crop straw, which is prepared by the following method:

[0047] S1. Removing surface wax: pulverize the straw samples with a pulverizer, soak in 1-2mol / L NaOH solution for 20-24h, wash with distilled water until neutral, and dry at 50-60°C;

[0048] S2. Hydrogen bond activation: use 50wt% H 3 PO 4 Soak in the solution for 20-24 hours, wash with distilled water until neutral, and dry at 50-60°C;

[0049] S3. Preparation of sodium cellulose: adding the activated straw powder into a 10-15mol / L NaOH solution, stirring and reacting for 2-4h, filtering and drying to obtain sodium cellulose;

[0050] S4. Modification: add long-chain monohalogenated alkanes to organic solvents, add cellulose sodium, react for 3-5 hours, filter, wash with distilled water, evenly spray 5wt% triethylamine, and dry at 50-60°C to obtain Modified cellulose;

[0051] Long-chain monohalogenated alkanes have the structure of formula I:

[0052]

[0053] Formula I; ...

Embodiment 3

[0057] A method for preparing modified crop straw, which is prepared by the following method:

[0058] S1. Removing surface wax: pulverize the rice straw sample with a pulverizer, soak in 1-2mol / L NaOH solution for 20-24h, wash with distilled water until neutral, and dry at 50-60°C;

[0059] S2. Hydrogen bond activation: use 50wt% H 3 PO 4 Soak in the solution for 20-24 hours, wash with distilled water until neutral, and dry at 50-60°C;

[0060] S3. Preparation of sodium cellulose: adding the activated straw powder into a 10-15mol / L NaOH solution, stirring and reacting for 2-4h, filtering and drying to obtain sodium cellulose;

[0061] S4. Modification: add long-chain monohalogenated alkanes to organic solvents, add cellulose sodium, react for 3-5 hours, filter, wash with distilled water, evenly spray 5wt% triethylamine, and dry at 50-60°C to obtain Modified cellulose;

[0062] Long-chain monohalogenated alkanes have the structure of formula I:

[0063]

[0064] Formul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com