Textile printing and dyeing wastewater treatment method

A technology for textile printing and dyeing and wastewater treatment, which is applied in the direction of oxidized water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of high salt detection at the outlet, many bubbles, and high chemical consumption. problem, achieve the effect of reducing energy waste and reducing the concentration of aniline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

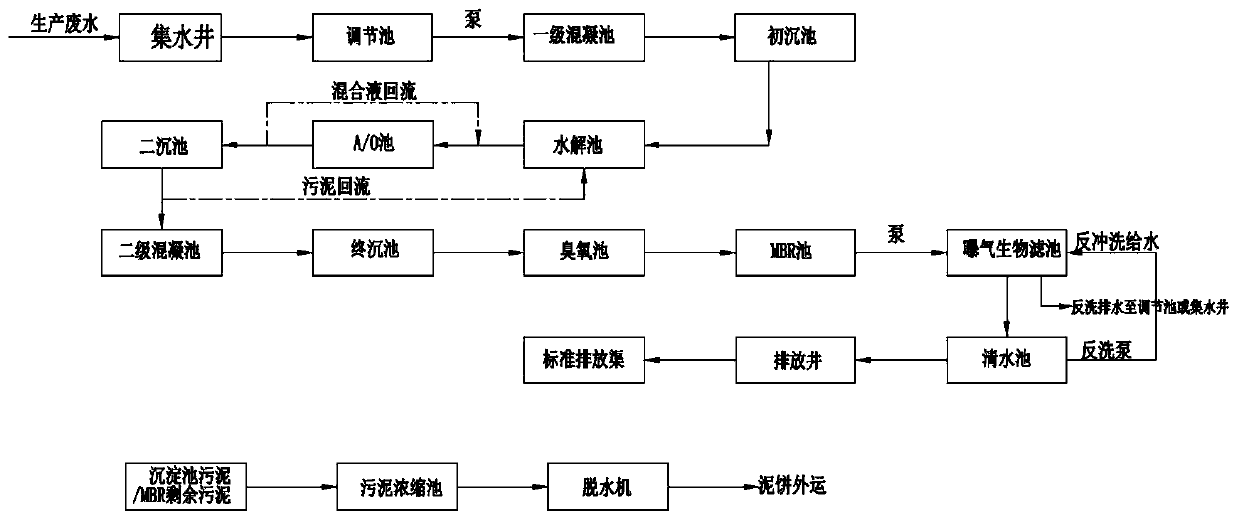

[0033] A kind of textile printing and dyeing wastewater treatment method, such as figure 1 As shown, it includes the following steps:

[0034] Step 1. Collecting waste water from the water collection well and entering the adjustment tank for adjustment and treatment: use the water collection well to collect the production wastewater in the textile printing and dyeing process, and pump the production wastewater in the water collection well to the adjustment pool to adjust the water quality and water quantity; among them, the adjustment An electromagnetic flowmeter is installed on the inlet pipe of the pool;

[0035] Step 2, primary coagulation tank treatment: After being regulated by the regulating tank, pump the production wastewater in the regulating tank to the primary coagulation tank for coagulation treatment;

[0036] Step 3, primary sedimentation tank treatment: After being treated in the primary coagulation tank, the production wastewater is pumped to the primary sedim...

Embodiment 2

[0047] A kind of textile printing and dyeing wastewater treatment method, such as figure 1 As shown, it includes the following steps:

[0048] Step 1. Collecting waste water from the water collection well and entering the adjustment tank for adjustment and treatment: use the water collection well to collect the production wastewater in the textile printing and dyeing process, and pump the production wastewater in the water collection well to the adjustment pool to adjust the water quality and water quantity; among them, the adjustment An electromagnetic flowmeter is installed on the inlet pipe of the pool;

[0049] Step 2, primary coagulation tank treatment: After being regulated by the regulating tank, pump the production wastewater in the regulating tank to the primary coagulation tank for coagulation treatment;

[0050] Step 3, primary sedimentation tank treatment: After being treated in the primary coagulation tank, the production wastewater is pumped to the primary sedim...

Embodiment 3

[0061] A kind of textile printing and dyeing wastewater treatment method, such as figure 1 As shown, it includes the following steps:

[0062] Step 1. Collecting waste water from the water collection well and entering the adjustment tank for adjustment and treatment: use the water collection well to collect the production wastewater in the textile printing and dyeing process, and pump the production wastewater in the water collection well to the adjustment pool to adjust the water quality and water quantity; among them, the adjustment An electromagnetic flowmeter is installed on the inlet pipe of the pool;

[0063] Step 2, primary coagulation tank treatment: After being regulated by the regulating tank, pump the production wastewater in the regulating tank to the primary coagulation tank for coagulation treatment;

[0064] Step 3, primary sedimentation tank treatment: After being treated in the primary coagulation tank, the production wastewater is pumped to the primary sedim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com