Starch-based high-stability Pickering emulsion and preparation method thereof

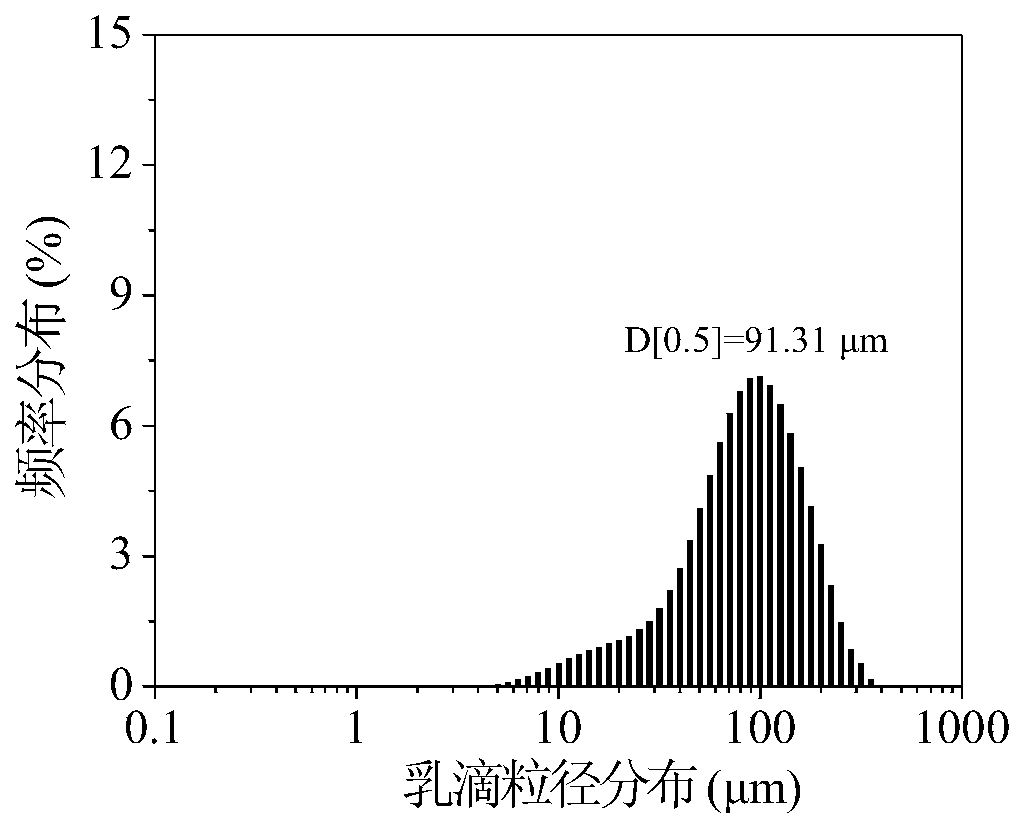

A highly stable, starch-based technology, applied in the field of lipid complex V-type crystalline starch and new food-grade amphiphilic Pickering emulsifiers, can solve the problems of human health hazards, limited application and other problems, and achieve the effect of uniform distribution of emulsion droplets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The preparation method of starch-based highly stable Pickering emulsion is characterized in that comprising the following steps and processing conditions:

[0058] (1) Prepare cornstarch into a starch slurry with a mass fraction of 5% on a dry basis, gelatinize in a boiling water bath for 2 hours under agitation, cool to 30° C., and continue stirring while adding 3 times the volume fraction of absolute ethanol drop by drop, Centrifuge and classify to obtain the precipitate, place it at 60°C and blow dry for 12 hours to obtain V-type crystalline starch;

[0059] (2) Melt lauric acid at 60° C. and continue stirring for 1 hour to form fluid lauric acid;

[0060] (3) Fully mix 1 part of the fluid lauric acid obtained in step (2) with 10 parts of the V-shaped crystalline starch obtained in step (1) and continue to stir for 1 hour, then place it at 40°C for 24 hours to obtain starch laurel Acid composite particles;

[0061] (4) The starch lauric acid composite particle obta...

Embodiment 2

[0065] The preparation method of starch-based highly stable Pickering emulsion is characterized in that comprising the following steps and processing conditions:

[0066] (1) Potato starch is prepared into a starch slurry with a mass fraction of 10% on a dry basis, gelatinized in a boiling water bath for 1 h under stirring conditions, and after cooling to 30° C., continuously stirring while adding 2 times the volume fraction of absolute ethanol dropwise, Centrifuge and classify to obtain the precipitate, place it at 60°C and blow dry for 12 hours to obtain V-type crystalline starch;

[0067] (2) Melt palmitic acid at 65°C and continue stirring for 2 hours to form fluid palmitic acid;

[0068] (3) Fully mix 1 part of the fluid palmitic acid obtained in step (2) with 5 parts of the V-shaped crystalline starch obtained in step (1) and continue to stir for 1 hour, then place it at 50°C for 24 hours to obtain starch palm Acid composite particles;

[0069] (4) The starch palmitic ...

Embodiment 3

[0072] The preparation method of starch-based highly stable Pickering emulsion is characterized in that comprising the following steps and processing conditions:

[0073] (1) Prepare cassava starch into a starch slurry with a mass fraction of 15% on a dry basis, gelatinize in a boiling water bath for 2 hours under stirring conditions, cool to 30° C., continue stirring while adding 4 times the volume fraction of absolute ethanol drop by drop, Centrifuge and classify to obtain the precipitate, place it at 60°C and blow dry for 12 hours to obtain V-type crystalline starch;

[0074] (2) Melt stearic acid at 70°C, and continue stirring for 1 hour to form fluid stearic acid;

[0075] (3) Fully mix 2 parts of the fluid stearic acid obtained in step (2) with 9 parts of the V-shaped crystalline starch obtained in step (1) and continue to stir for 1 hour, then place it at 40°C for 24 hours to obtain the starch Stearic acid composite particles;

[0076] (4) The starch stearic acid comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com