Nickel-iron hydrogenase model substance, ionic nickel-iron hydrogenase model substance, preparation method and application thereof

A technology of nickel-iron hydrogenase and model substance, applied in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve structural instability, lack of catalytic activity, hindering Biomimetic enzyme hydrogen production development and other issues, to achieve the effect of stable crystal structure, easy implementation and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] For the nickel-iron hydrogenase model substance described above, the second aspect of the embodiment of the present invention provides a method for preparing the nickel-iron hydrogenase model substance, comprising the following steps:

[0054] S100, preparing the first intermediate product

[0055] NiCl 2 ·6H 2 O and NiCl 2 ·6H 2 The 2-(2-pyridine)-benzimidazole of the amount of substance such as O joins in the ethanol ethanol, after stirring at room temperature, decompression suction filtration obtains the first intermediate product; Wherein the molecular formula of the first intermediate product is Ni[N 2 ]Cl 2 , its chemical structure is:

[0056]

[0057] The reaction process of step S100 is as follows:

[0058]

[0059] In the reaction process of step S100, due to NiCl 2 ·6H 2 O coordination H 2 O is easy to leave, forming a vacant site, the reaction with the dinitrogen-containing conjugated ligand is spontaneous, and the first intermediate product p...

Embodiment 1

[0112] The first intermediate product is prepared by the following preparation method:

[0113] 1.19g or 5mmol of NiCl 2 ·6H 2 O and 0.98g, that is, 5mmol of 2-(2-pyridine)-benzimidazole were added to a 250mL round-bottomed flask containing magnetons, 100mL of ethanol was added, and after stirring at room temperature for 5h, after heating to 40°C, suction filtration under reduced pressure, The first intermediate product Ni[N] in the form of light green powder can be obtained 2 ] Cl 2 ; Wherein the first intermediate product Ni[N 2 ] Cl 2 The yield of is 1.5 g, the yield is 93%.

Embodiment 2

[0115] Model 1 was prepared by the following preparation steps:

[0116] in N 2 Under protection, the first intermediate product Ni[N 2 ] Cl 2 With 616mg or 1mmol of Fe(pdt)(CO) 2 (dppe) was dissolved in 50 mL of anhydrous acetone, stirred at room temperature for 10 min, and 120 mg (1.1 mmol) of NaBF was added 4 , after reacting for 2h, filter, vacuum dry to remove anhydrous acetone, obtain model 1, the molecular formula of model 1 is (dppe)(CO)Fe(μ-SCH 2 CH 2 CH 2 S)(μ-Cl)Ni[N 2 ](BF 4 );

[0117] Among them, model substance 1 is a reddish-brown powder, and its yield is 790 mg, and the yield rate is 80%.

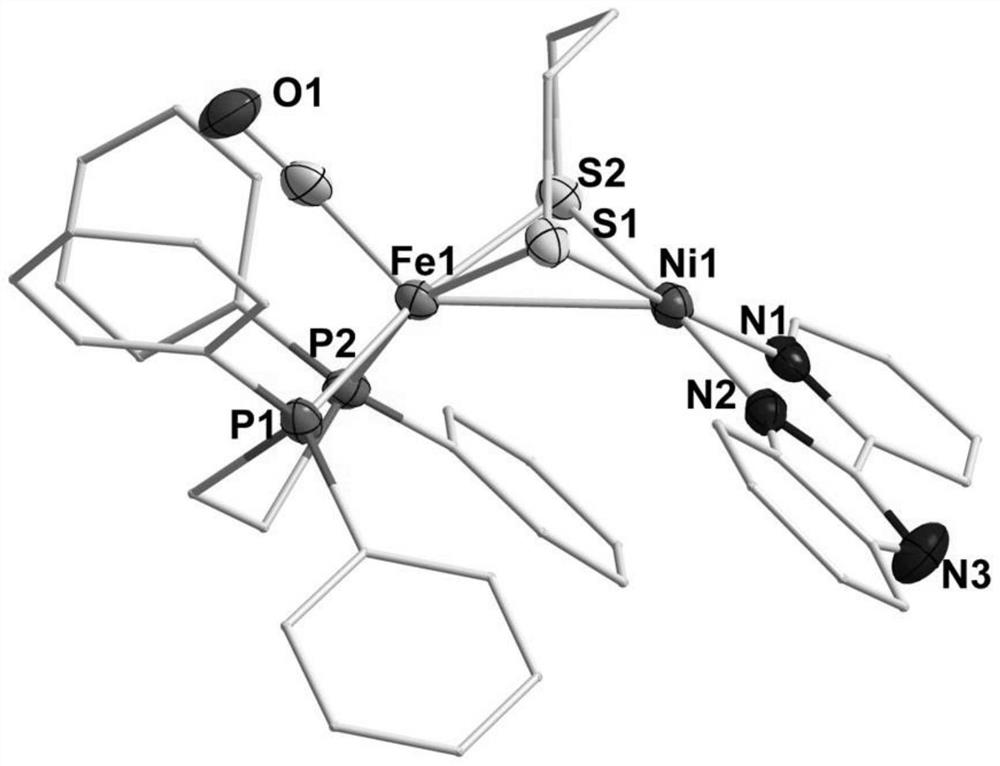

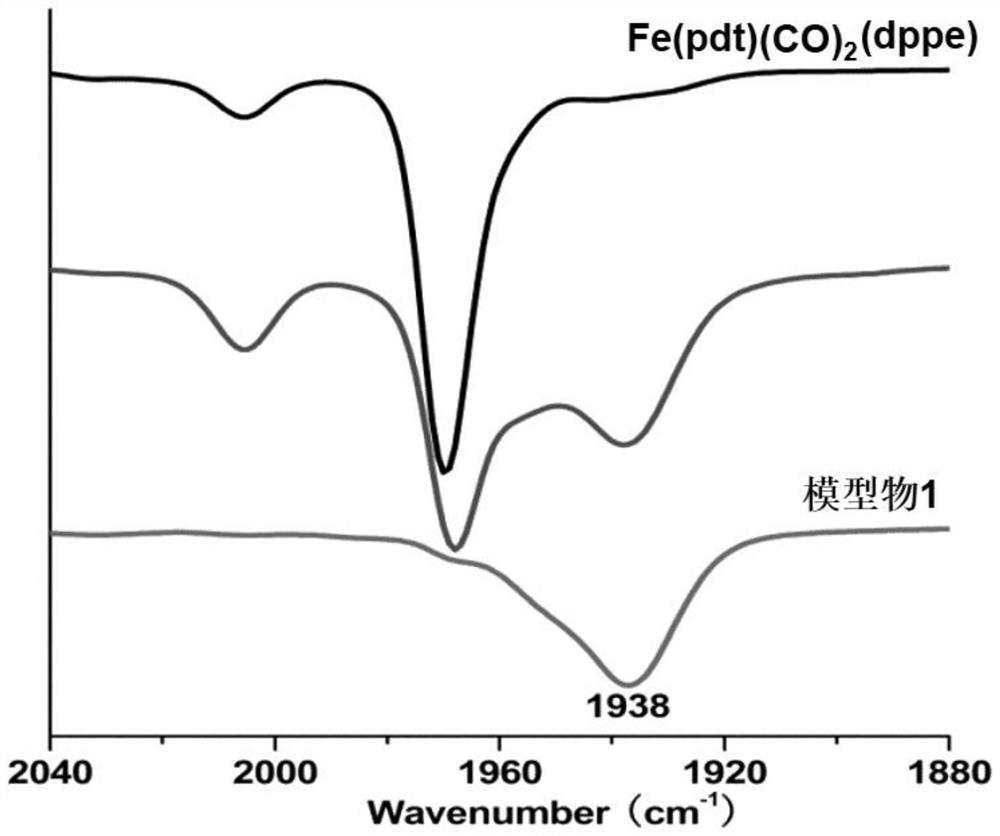

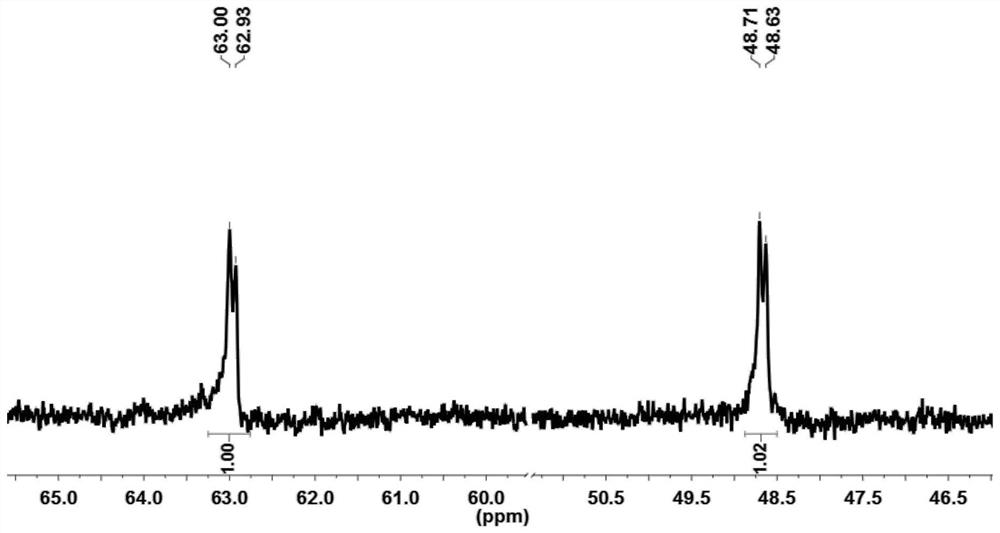

[0118] combine Figure 2 to Figure 3 , the characterization data of model object 1 are as follows: FI-IR(acetone,ν CO ):1938cm -1 ; 31 P{ 1 H} NMR (202MHz, acetone): dd peak, 63, 48ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com