Special fertilizer for navel orange planting and preparation method thereof

A special fertilizer, navel orange technology, which is applied in the field of special fertilizer for navel orange planting, can solve the problems of long-term fertilizer effect, nutrient loss, soil and food nutrient imbalance, etc., to reduce planting costs, improve land fertility, and facilitate long-term development Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

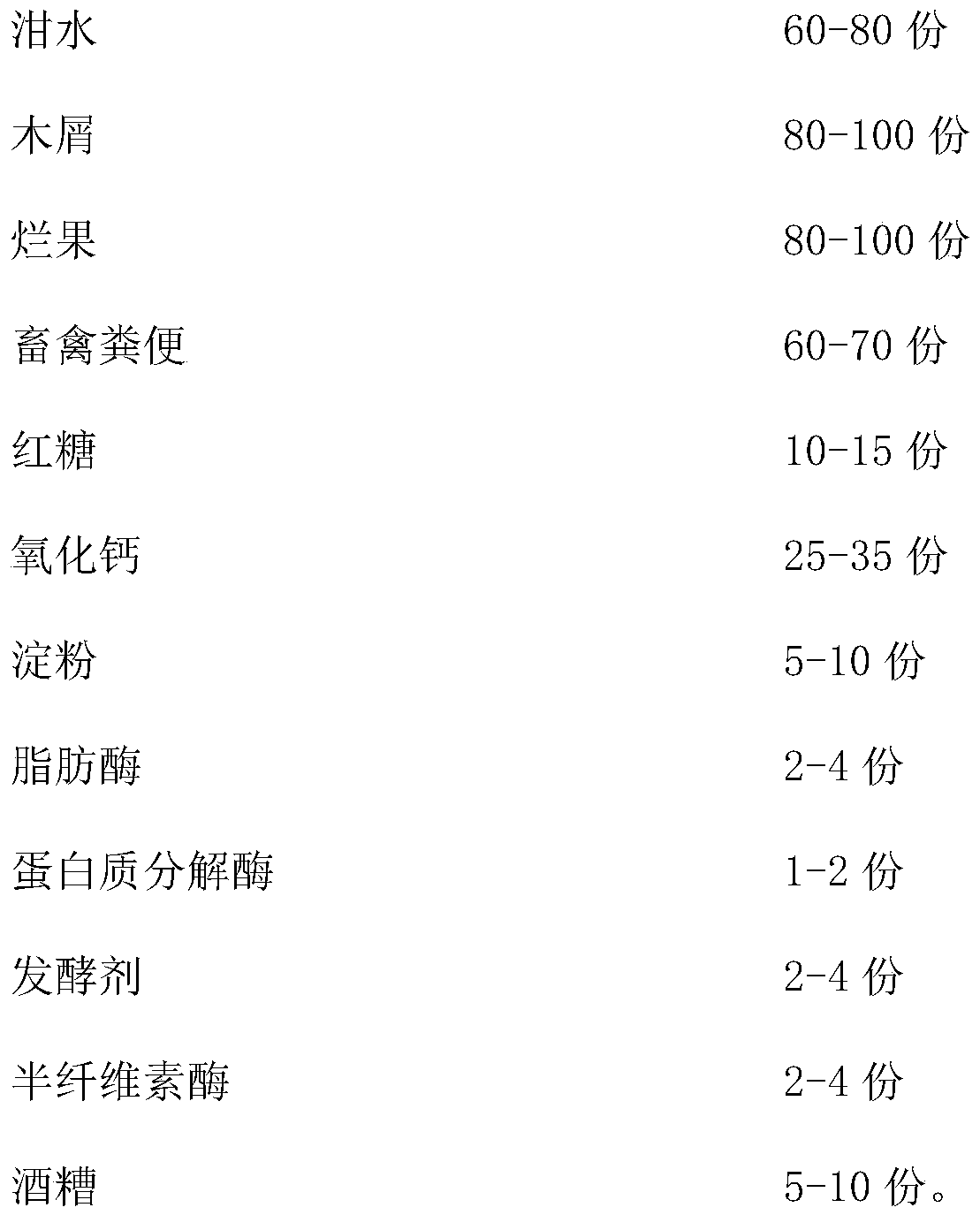

[0045] A special fertilizer for navel orange planting, calculated in parts by weight, is composed as follows:

[0046]

[0047] The processing technology of special fertilizer for navel orange planting comprises the following steps:

[0048] Step 1, swill pretreatment: the swill material obtained by filtering the swill through a 100-mesh screen is processed by an extruder to obtain a primary treatment swill material; then the primary treatment swill material is crushed into a slurry, and starch and lipase are added, and stirred Evenly, natural treatment at 24-32°C for 15-20h, after that, add 5 parts of calcium oxide, stir well, and treat at 45-60°C for 1.5-2.0h to obtain secondary treatment swill materials; Proteolytic enzymes are added to the secondary treatment swill material, sealed at 24-32°C for 15-20 hours, then dried and crushed to obtain swill treatment powder;

[0049] Step 2. Sawdust pretreatment: First, crush the sawdust into fine powder of more than 60 meshes, ...

Embodiment 2

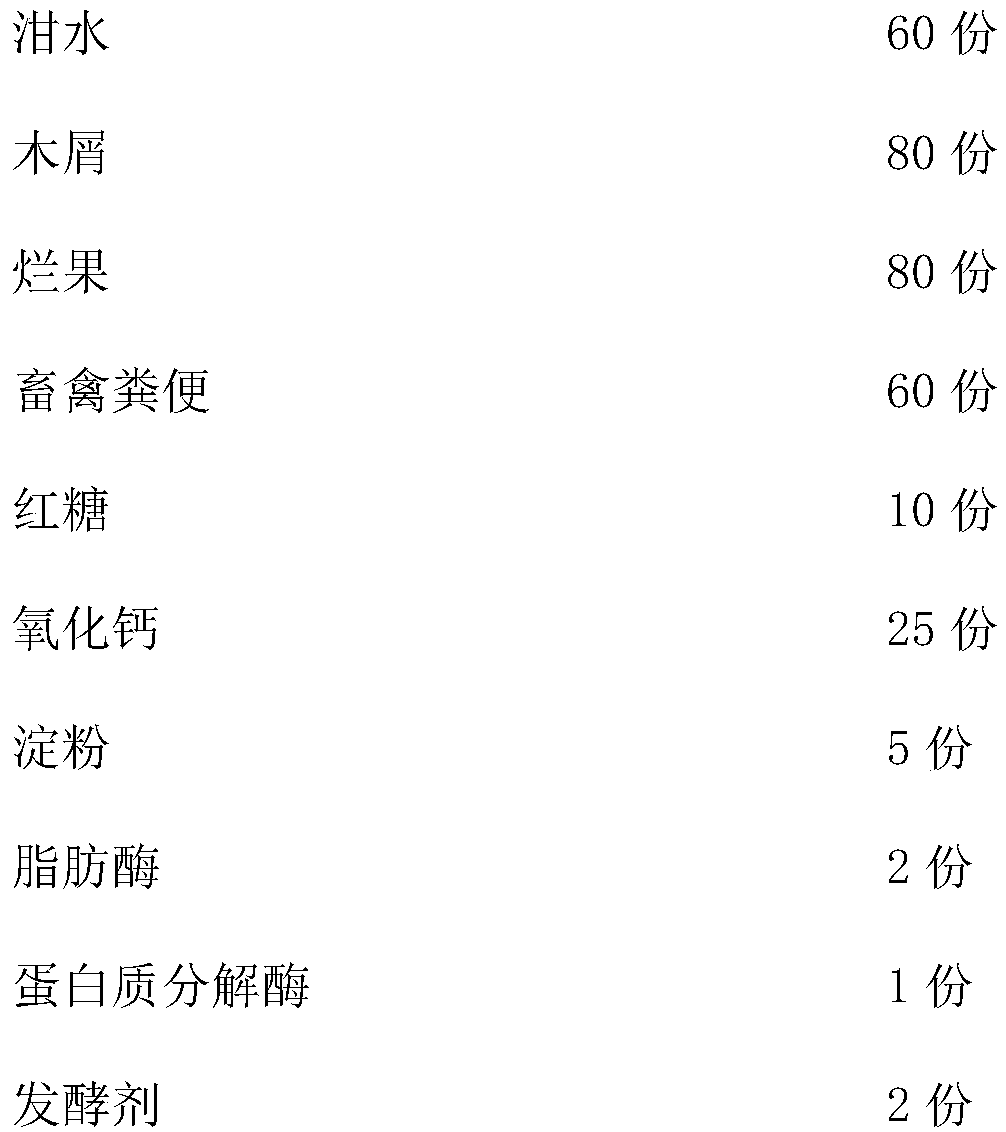

[0056] A special fertilizer for navel orange planting, calculated in parts by weight, is composed as follows:

[0057]

[0058] The processing technology of special fertilizer for navel orange planting comprises the following steps:

[0059] Step 1, swill pretreatment: the swill material obtained by filtering the swill through a 100-mesh screen is processed by an extruder to obtain a primary treatment swill material; then the primary treatment swill material is crushed into a slurry, and starch and lipase are added, and stirred Evenly, natural treatment at 24-32°C for 15-20h, after that, add 5 parts of calcium oxide, stir well, and treat at 45-60°C for 1.5-2.0h to obtain secondary treatment swill materials; Proteolytic enzymes are added to the secondary treatment swill material, sealed at 24-32°C for 15-20 hours, then dried and crushed to obtain swill treatment powder;

[0060] Step 2. Sawdust pretreatment: First, crush the sawdust into fine powder of more than 60 meshes, ...

Embodiment 3

[0065] A special fertilizer for navel orange planting, calculated in parts by weight, is composed as follows:

[0066]

[0067]

[0068] The processing technology of special fertilizer for navel orange planting comprises the following steps:

[0069] Step 1, swill pretreatment: the swill material obtained by filtering the swill through a 100-mesh screen is processed by an extruder to obtain a primary treatment swill material; then the primary treatment swill material is crushed into a slurry, and starch and lipase are added, and stirred Evenly, natural treatment at 24-32°C for 15-20h, after that, add 5 parts of calcium oxide, stir well, and treat at 45-60°C for 1.5-2.0h to obtain secondary treatment swill materials; Proteolytic enzymes are added to the secondary treatment swill material, sealed at 24-32°C for 15-20 hours, then dried and crushed to obtain swill treatment powder;

[0070] Step 2. Sawdust pretreatment: First, crush the sawdust into fine powder of more than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com