Co-self-assembled explosive with dense unit cell accumulation structure and preparation method thereof

A self-assembly and explosive technology, which is used in explosive processing equipment, explosives, nitrated acyclic/alicyclic/heterocyclic amine explosive compositions, etc., can solve the detonation performance of modified HNIW explosives, reduce HNIW energy density, reduce HNIW sensitivity and other issues, to achieve the effect of inhibiting the formation of hot spots, excellent safety performance, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

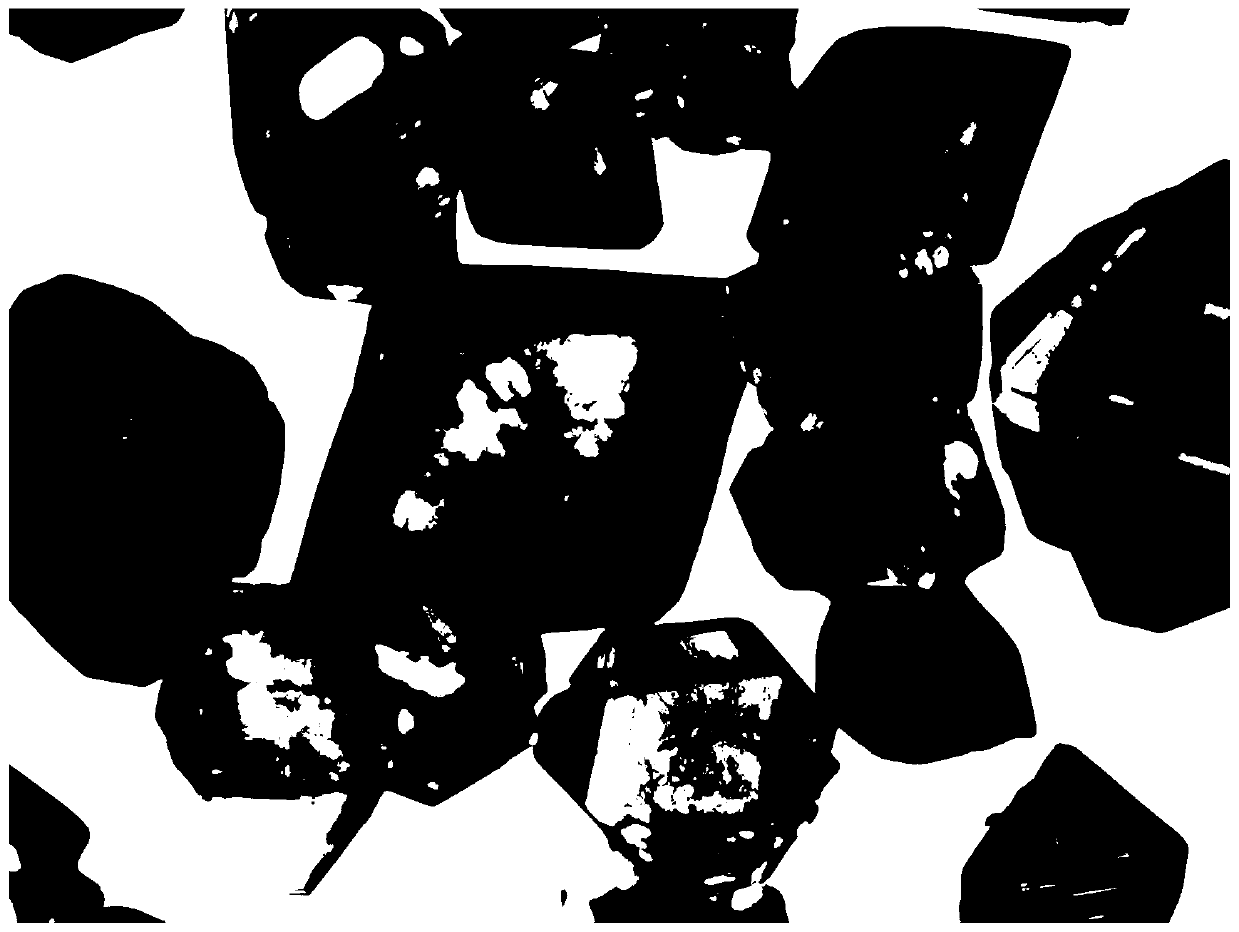

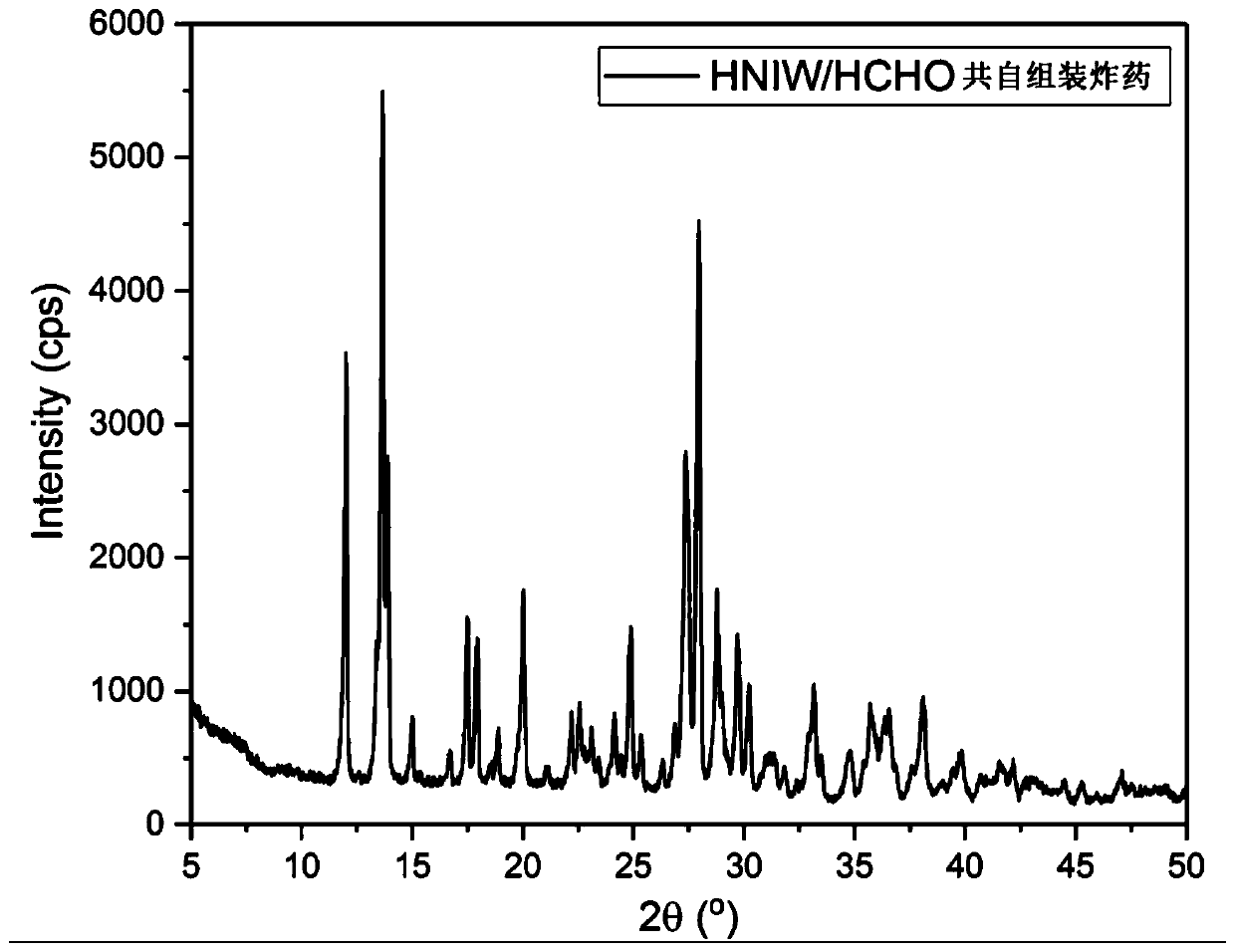

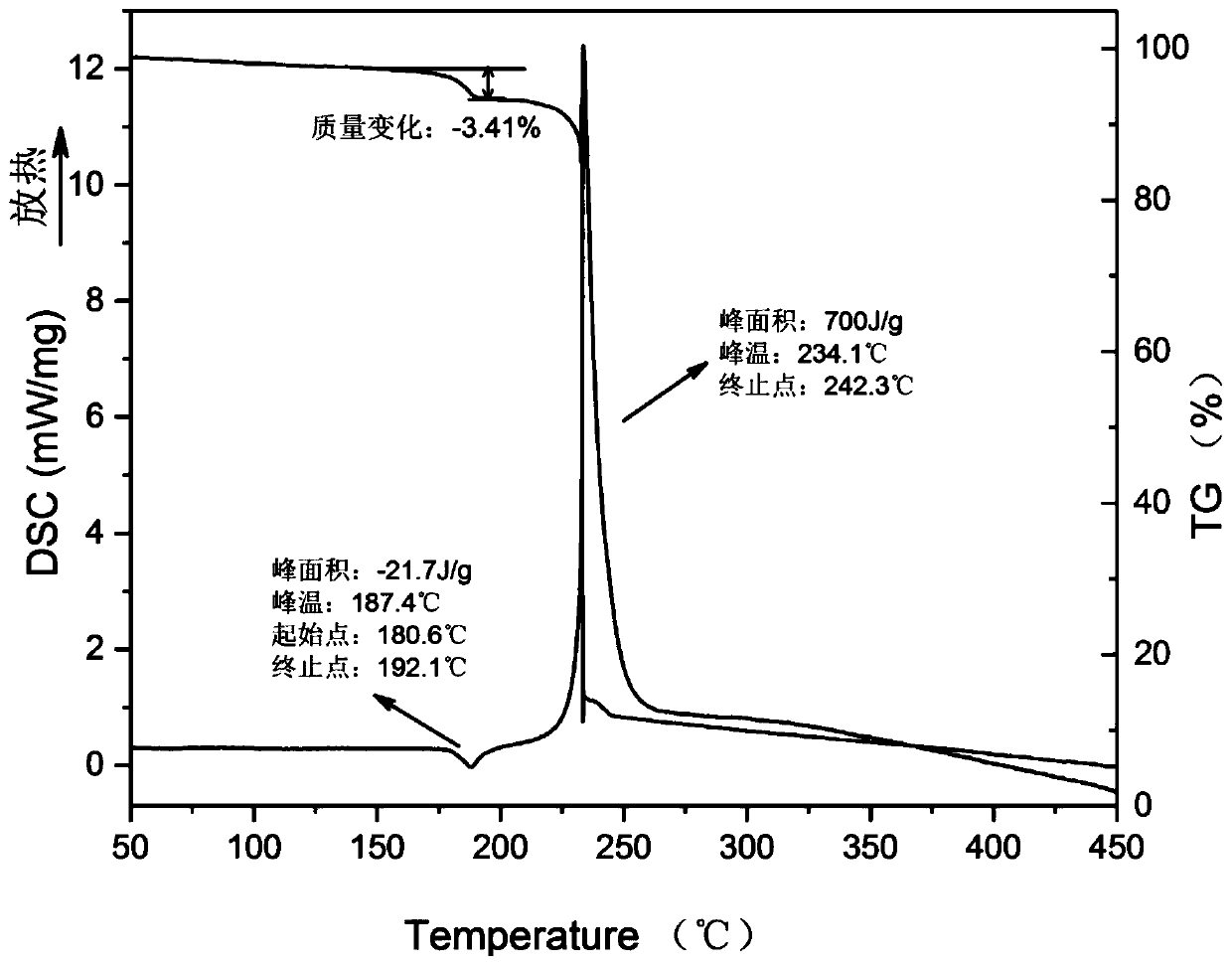

Image

Examples

Embodiment 1

[0040](1) Weigh 10g of paraformaldehyde raw material and place it in a 100ml flask, connect the flask to an Erlenmeyer flask containing 20ml of toluene through an adapter and a gas tube at the mouth of the bottle, and place the flask in an oil bath in a fume hood Heat to 80°C, stop heating until the toluene solvent has no gas bubbling, and obtain anhydrous formaldehyde solution with a concentration of about 2mol / L;

[0041] (2) Put 5g of HNIW raw material in a 250ml Erlenmeyer flask, measure 20ml of methyl formate and add it, stir it with a magnetic force at 500r / min until completely dissolved, and obtain an anhydrous HNIW solution with a concentration of about 0.25g / ml;

[0042] (3) Add the anhydrous formaldehyde solution obtained in step (1) into the HNIW solution, and fully mix with 500r / min magnetic stirring;

[0043] (4) Using the low-temperature anti-solvent crystallization method, place the crystallization solution in a cryostat at 5°C, slowly add 80ml of n-hexane dropw...

Embodiment 2

[0046] (1) Weigh 20g of paraformaldehyde raw material and place it in a 50ml flask, connect the flask to the Erlenmeyer flask containing 20ml of ether through an adapter and a gas tube at the mouth of the bottle, and place the flask in an oil bath in a fume hood Heat to 100°C, stop heating until the ether solvent has no gas bubbles, and obtain anhydrous formaldehyde solution with a concentration of about 2.5mol / L;

[0047] (2) Put 5g of HNIW raw material in a 250ml Erlenmeyer flask, measure 50ml of tetrahydrofuran, add it, and stir it magnetically at 800r / min until it is completely dissolved to obtain an anhydrous HNIW solution with a concentration of about 0.1g / ml;

[0048] (3) Take 5ml of the anhydrous formaldehyde solution obtained in step (1) and add it to the HNIW solution, and mix thoroughly with 800r / min magnetic stirring;

[0049] (4) Using the low-temperature anti-solvent crystallization method, place the crystallization solution in a cryostat at -30°C, slowly add 150...

Embodiment 3

[0052] (1) Weigh 10g of paraformaldehyde raw material and place it in a 100ml flask, connect the flask to the Erlenmeyer flask containing 120ml of chloroform through an adapter and a gas tube at the mouth of the bottle, and place the flask in an oil bath in a fume hood Heat to 120°C, stop heating until the chloroform solvent has no gas bubbles, and obtain anhydrous formaldehyde solution with a concentration of about 0.3mol / L;

[0053] (2) Put 5g of HNIW raw material in a 250ml Erlenmeyer flask, add 6.3ml of acetone, and stir magnetically at 100r / min until completely dissolved to obtain an anhydrous HNIW solution with a concentration of about 0.8g / ml;

[0054] (3) Take 7ml of the anhydrous formaldehyde solution obtained in step (1) and add it to the HNIW solution, and mix thoroughly with 100r / min magnetic stirring;

[0055] (4) Using the low-temperature anti-solvent crystallization method, place the crystallization solution in a cryostat at 10°C, slowly add 40ml of n-hexane dro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com