Method for improving dissolving speed of rubber in asphalt

A technology of dissolving speed and asphalt, which is applied in the direction of building components, building insulation materials, buildings, etc., can solve the problems of difficult production and construction, difficult storage, too fast performance decay, etc., to improve the softening point of asphalt and anti-aging performance, improve Elasticity of the rubber compound and the effect of increasing the dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

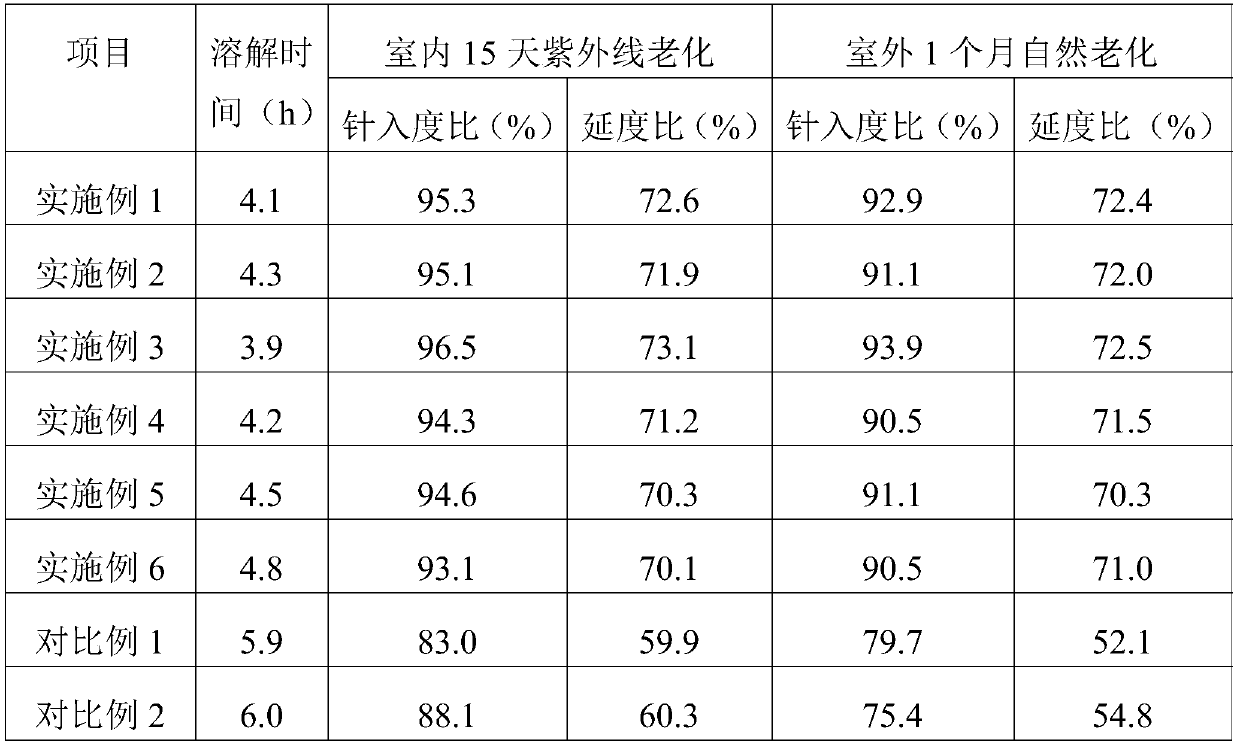

Examples

Embodiment 1

[0018] The method for improving the dissolution rate of rubber in asphalt comprises the following steps:

[0019] S1. Mix natural rubber: asphalt: aromatic oil: carbon black at a volume ratio of 100:23:15:21 for 5 minutes at a temperature of 100° C., mix them evenly, and press and granulate to obtain a rubber compound;

[0020] S2. Soak the mixed rubber in aromatic oil for 12 hours, and the aromatic oil is 1 times the volume of the mixed rubber to make it swell;

[0021] S3. Take out the soaked mixed rubber and put it into the asphalt. The mass ratio of mixed rubber to asphalt is 3:100. At a temperature of 150°C, stir at 300r / min, then turn it to 800r / min, and then turn it to 300r / min. After stirring for min, it was dissolved to obtain a natural rubber modified asphalt sample.

Embodiment 2

[0023] The method for improving the dissolution rate of rubber in asphalt comprises the following steps:

[0024] S1. Mix natural rubber: bitumen: cosolvent: reinforcing agent at a volume ratio of 100:45:40:63 for 10 minutes at a temperature of 140°C, mix them evenly, and press and granulate to obtain a rubber compound. The reinforcing agent is composed of carbon black and cetyl alcohol at a volume ratio of 1:1;

[0025] S2. Put the mixed rubber into the co-solvent, the mass ratio of the mixed rubber to asphalt is 2:25, soak for 30h, the co-solvent is 3 times the volume of the mixed rubber to make it swell;

[0026] The co-solvents in the above steps S2 and S3 are composed of polystyrene and aromatic oil with a volume ratio of 1:2;

[0027] S3. Take out the soaked mixed rubber and put it into the asphalt at a temperature of 200°C. Stir at 800r / min, then turn to 1200r / min to stir, and then turn to 800r / min to stir and dissolve to obtain a natural rubber modified asphalt sample...

Embodiment 3

[0029] The method for improving the dissolution rate of rubber in asphalt comprises the following steps:

[0030] S1. Mix natural rubber: asphalt: cosolvent: reinforcing agent at a volume ratio of 100:34:27:42 for 8 minutes at a temperature of 120° C., mix it evenly, and press it into granules to obtain a rubber compound. The above The reinforcing agent is composed of carbon black, cetyl alcohol and stearyl alcohol with a volume ratio of 1:2.5:3.2;

[0031] S2. Soak the mixed rubber in a cosolvent for 24 hours, and the cosolvent is twice the volume of the mixed rubber to make it swell;

[0032] The co-solvents in the above steps S2 and S3 are composed of polystyrene, aromatic oil, and methylparaben with a volume ratio of 1:2:2;

[0033] S3. Take out the soaked mixed rubber and put it into asphalt. The mass ratio of mixed rubber to asphalt is 1:20. At a temperature of 170°C, stir at 500r / min, then turn to 1000r / min, and then turn to 500r / min. After stirring for min, it was di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com