Method for controlled preparation of graphene fibers by using microfluidic technology

A graphene fiber and microfluidic technology, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, rayon chemical post-treatment, etc., can solve the problems of controllable fiber micro-morphology, achieve good uniformity, good continuity, The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

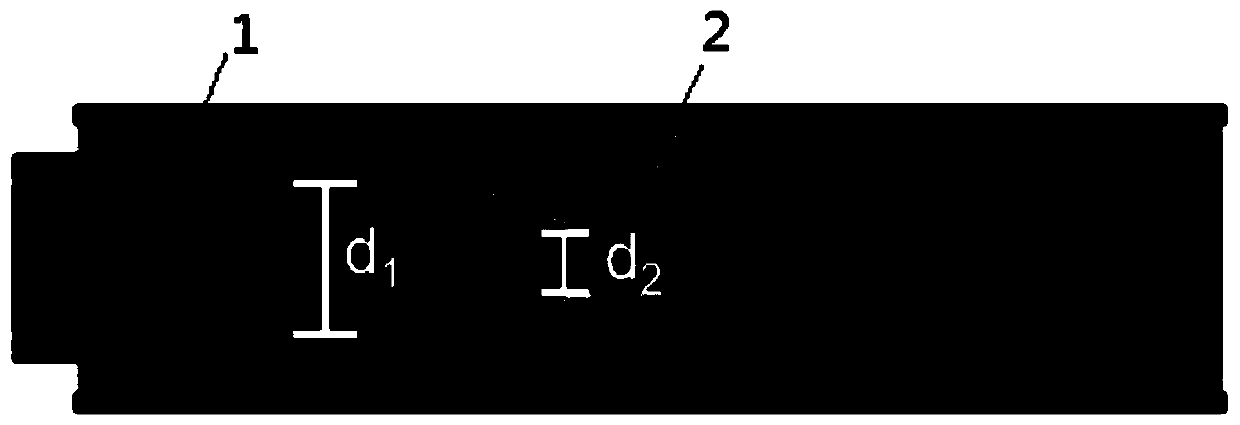

Embodiment 1

[0041] The inner phase is a graphene oxide aqueous solution with a mass concentration of 10 mg / mL, and the outer phase is a mixed solution of water / ethanol (volume ratio 1:4) with a mass fraction of calcium chloride of 10%. d 1 600μm, d 2 is 400 μm; the inner diameter of the external phase channel is 800 μm. The flow rate of the internal phase fluid is 4mL / h, and the flow rate of the external phase fluid is 20mL / h. The internal phase solution is passed into the internal phase channel 1 to control the internal and external phase flow rate. As time goes on, the graphene oxide aqueous solution passed into the internal phase channel 1 flows into the external phase In the channel, solidify under the action of the external phase fluid to obtain continuous gel-like graphene oxide fibers, and then pass it into a mixed solution of water / ethanol (volume ratio 1:4) with a mass fraction of calcium chloride of 10% , soaked for 30 minutes, took out the fibers, washed them with ethanol and...

Embodiment 2

[0043] The inner phase is a graphene oxide aqueous solution with a mass concentration of 10 mg / mL, and the outer phase is a mixed solution of water / ethanol (volume ratio 1:4) with a mass fraction of calcium chloride of 10%. d 1 600μm, d 2 is 400 μm; the inner diameter of the external phase channel is 800 μm. The flow rate of the internal phase fluid is 3mL / h, the flow rate of the external phase fluid is 18mL / h, and the internal phase is passed into the internal phase channel 1 to obtain continuous gel-like graphene oxide fibers, which are then passed into a calcium chloride with a mass fraction of 10%. Soak in water / ethanol (volume ratio: 1:4) mixed solution for 30 minutes, take out the fiber, wash with ethanol and deionized water respectively, and vacuum dry at 60°C for 2 hours to obtain dry continuous graphene oxide fiber. Finally, immerse the obtained graphene oxide fibers in a hydroiodic acid solution with a mass concentration of 40%, react at 90°C for 4h, wash with etha...

Embodiment 3

[0045] The inner phase is a graphene oxide aqueous solution with a mass concentration of 10 mg / mL, and the outer phase is a mixed solution of water / ethanol (volume ratio 1:4) with a mass fraction of calcium chloride of 10%. d 1 600μm, d 2 is 200 μm; the inner diameter of the external phase channel is 800 μm. The flow rate of the internal phase fluid is 4mL / h, the flow rate of the external phase fluid is 20mL / h, and the internal phase is passed into the internal phase channel 1 to obtain continuous gel-like graphene oxide fibers, which are then passed into a calcium chloride with a mass fraction of 10%. Soak in water / ethanol (volume ratio: 1:4) mixed solution for 30 minutes, take out the fiber, wash with ethanol and deionized water respectively, and vacuum dry at 60°C for 2 hours to obtain dry continuous graphene oxide fiber. Finally, immerse the obtained graphene oxide fibers in a hydroiodic acid solution with a mass concentration of 40%, react at 90°C for 4h, wash with etha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com