Quick-frozen wrapped bean curd and preparation method thereof

A technology of tofu and slurry, which is applied in the field of food processing, can solve problems such as overswelling, unclear key control points, and quick-frozen tofu coating with agglomeration, so as to maintain freshness, super water absorption capacity of soup, and reduce microbial growth. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

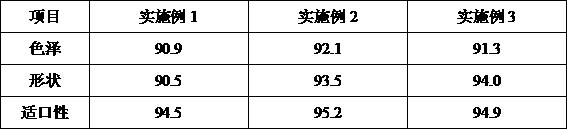

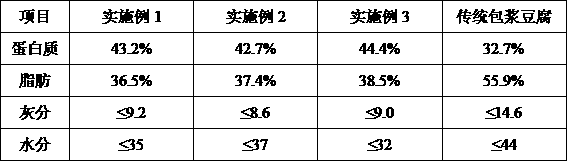

Examples

Embodiment 1

[0030] A kind of preparation method of quick-frozen coated tofu

[0031] (1) Soaking: Select high-quality northeast non-transgenic soybeans with a soybean protein content of more than 40% for soaking and peeling treatment to obtain peeled soybeans for use. The soaking is 9.5°C water temperature for 11 hours;

[0032] (2) Pulping: Dehulled soybeans are subjected to refining treatment, and the temperature of the machine is lowered while refining. Carry out pulping treatment, pass through a 100-mesh sieve for three times, and get the slurry for subsequent use;

[0033] (3) Burning pulp: Boil at 100°C for 5 minutes, pass through a 350-mesh sieve after boiling, and then point pulp at 80°C to obtain sour water tofu for later use, and the pH value of sour water tofu is 7;

[0034] (4) Packing: sour tofu is packaged, the temperature of the package is not lower than 60°C, and the tofu for every 20 catties of beans must be wrapped within 15 minutes;

[0035] (5) Squeeze: press the air...

Embodiment 2

[0040] A kind of preparation method of quick-frozen coated tofu

[0041] (1) Soaking: Select high-quality Northeast non-transgenic soybeans with a soybean protein content of more than 40% for soaking and peeling treatment to obtain peeled soybeans for use, soaking in water at 15°C for 9 hours;

[0042] (2) Pulping: Dehulled soybeans are subjected to refining treatment, and the temperature of the machine is lowered while refining. Carry out pulping treatment, pass through a 100-mesh sieve for three times, and get the slurry for subsequent use;

[0043] (3) Burning pulp: Boil at 103°C for 5 minutes, pass the slurry through a 350-mesh sieve after boiling, and then point the slurry at 85°C to obtain sour water tofu for later use, and the pH value of sour water tofu is 7.5;

[0044] (4) Wrapping: sour tofu is wrapped, the temperature of the wrapping is 65°C, and the tofu of every 20 catties of beans must be wrapped within 15 minutes;

[0045] (5) Squeeze: press the air press at 0...

Embodiment 3

[0050] A kind of preparation method of quick-frozen coated tofu

[0051] (1) Soaking: Select high-quality Northeast non-transgenic soybeans with a soybean protein content of more than 40% for soaking and peeling treatment to obtain peeled soybeans for use, soaking in water at 23°C for 5.5 hours;

[0052](2) Pulping: Dehulled soybeans are subjected to refining treatment, and the temperature of the machine is lowered while refining. Carry out pulping treatment, pass through a 100-mesh sieve for three times, and get the slurry for subsequent use;

[0053] (3) Burning pulp: Boil at 107°C for 5 minutes, pass the slurry through a 350-mesh sieve after boiling, and then point pulp at 90°C to obtain sour water tofu for later use. The pH value of sour water tofu is 8;

[0054] (4) Wrapping: sour tofu is wrapped, the temperature of the wrapping is 70°C, and the tofu of every 20 catties of beans must be wrapped within 15 minutes;

[0055] (5) Squeeze: press the air press at 0.4Mpa for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com