Totally-enclosed thermal coupling biological drying reaction device and method

A biological drying and reaction device technology, applied in the field of solid waste resource utilization, can solve the problems of high investment and operating costs of heat pumps, large amount of conditioner addition, high operating costs, etc., to shorten the total biological drying time, save The effect of removing waste gas treatment and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

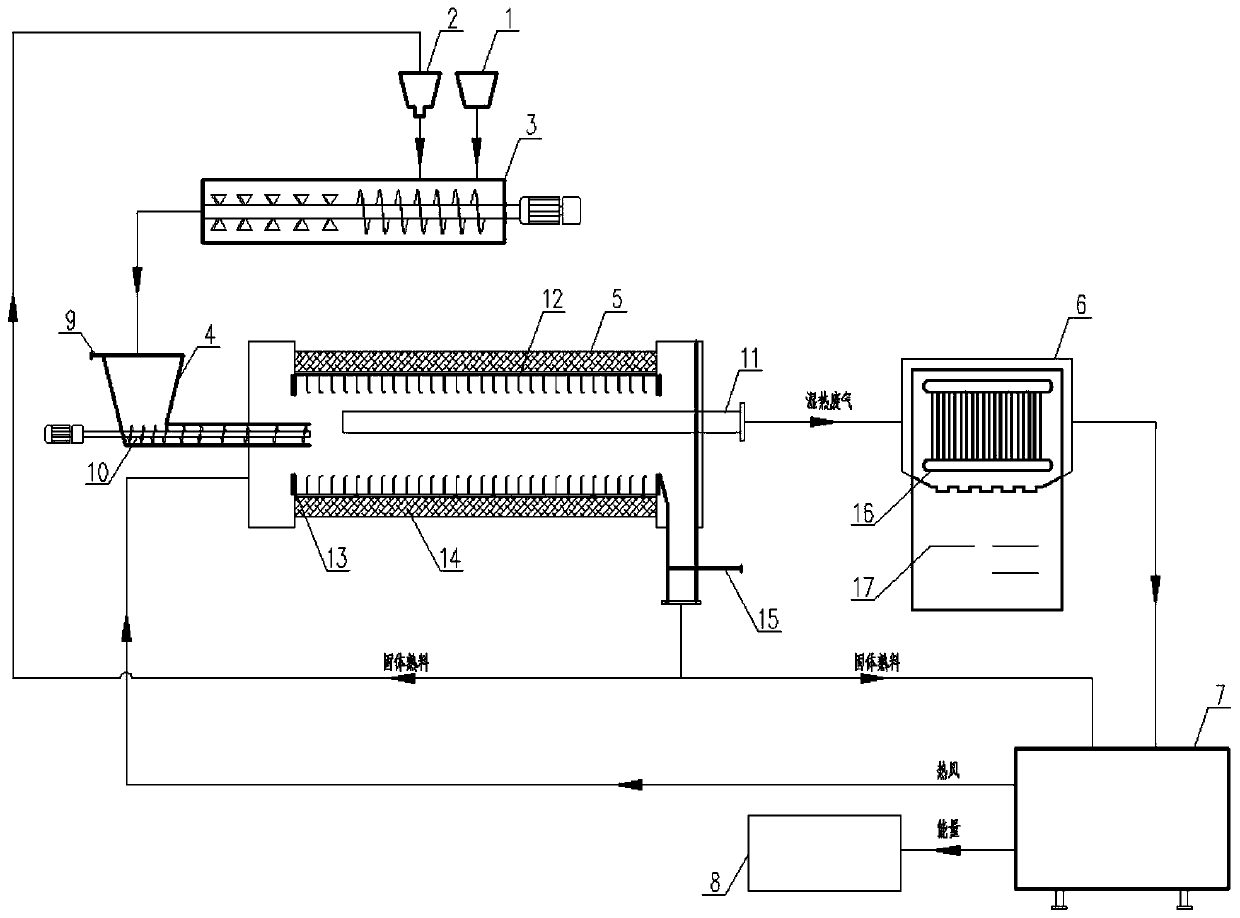

[0024] The high-moisture organic waste to be treated in the raw material silo 1 and the biologically dried clinker in the clinker silo 2 are sent to the mixing and crushing integrated device 3 at a weight ratio of 1:0.1-2 for mixing and crushing. After crushing, most of the particle size of the mixed material is between 2 and 20mm, and the water content is between 50% and 65%. The sealing valve 9 is opened, and the mixed material that meets the requirements of particle size and water content is sent to the sealed feeding device 4 The sealing valve 9 is closed, the gradual expansion feed screw 10 is opened, and the mixed material inside the sealed feed device 4 is opened by the gradual expansion feed screw 10 and sent to the rotary biological drying device 5, and the hot air from the combustion device 7 Send it into the rotary biological drying device 5 to provide oxygen and high background temperature for the biological drying reaction of the mixed material. After 3-4 days of b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com