A method for synthesizing zsm-5 in situ with kaolin microspheres

A ZSM-5, kaolin microsphere technology, applied in chemical instruments and methods, crystalline aluminosilicate zeolite, physical/chemical process catalysts, etc., can solve problems such as complex processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

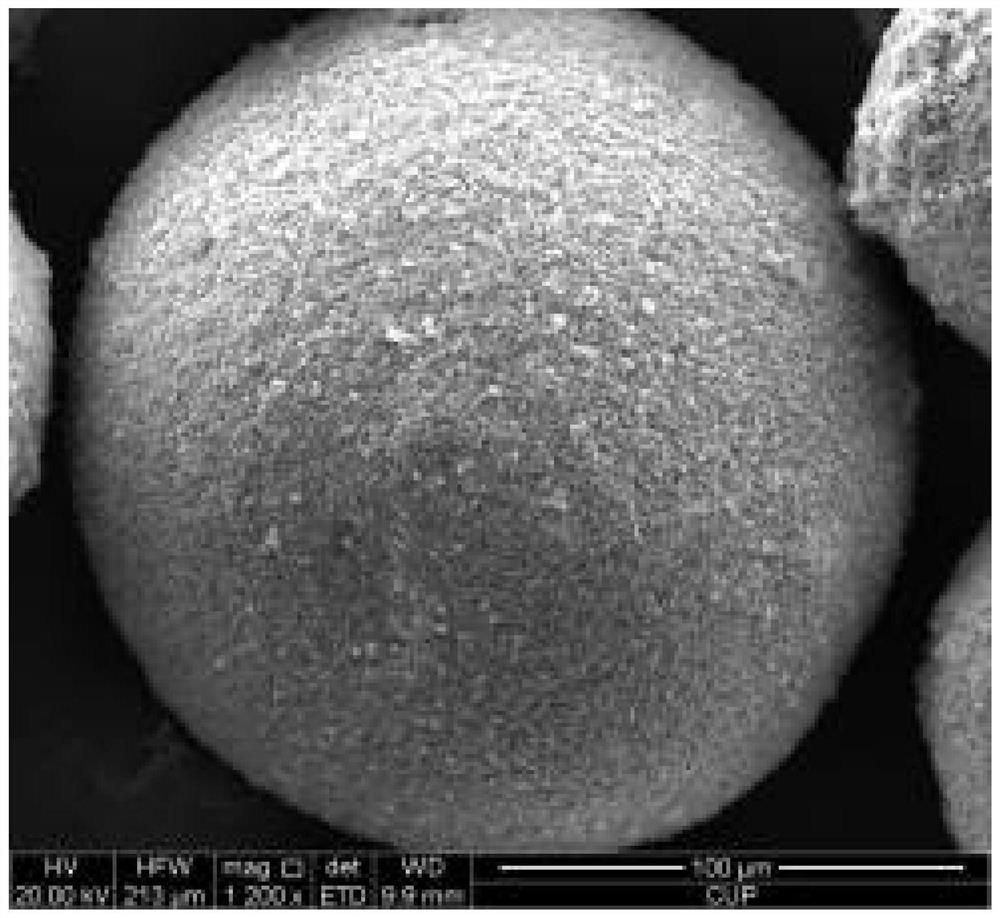

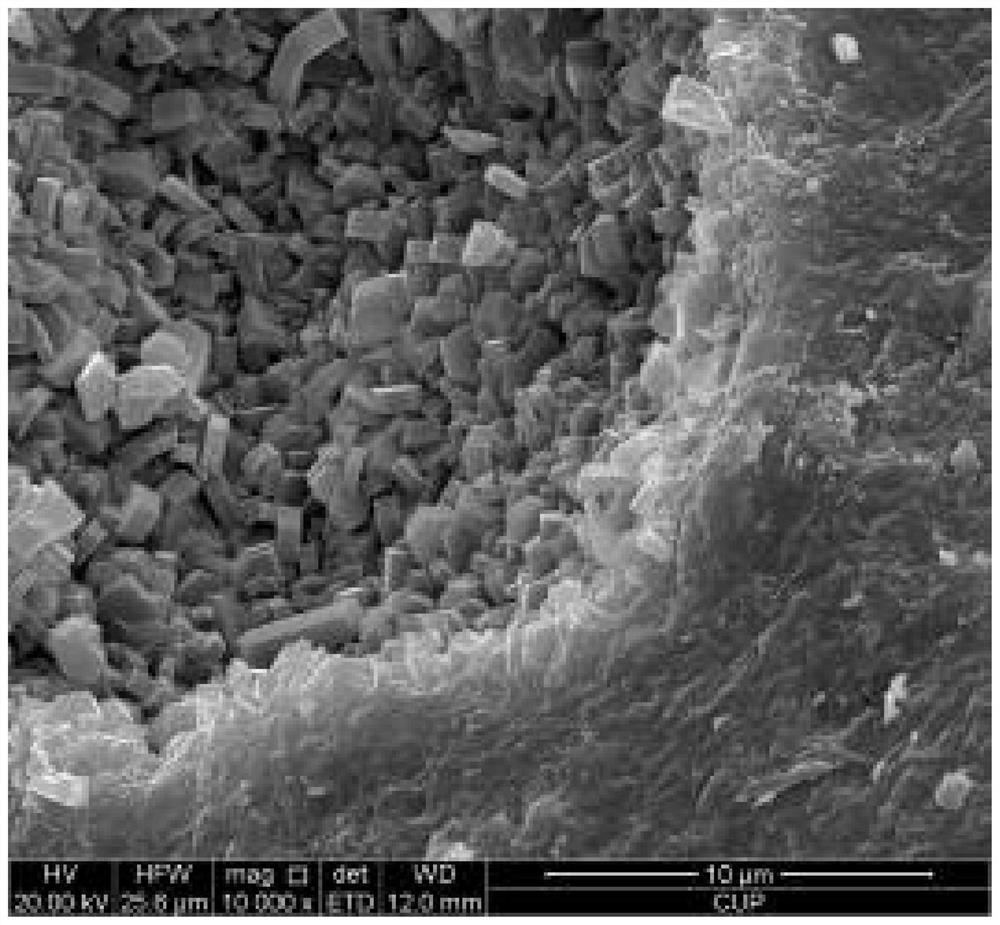

[0042] 10 kg of kaolin (dry basis) and water were prepared into a slurry with a solid content of 35%, and 155 g of sodium hydroxide was added as a dispersant for spray molding. The obtained spray soil balls were roasted at 900°C for 4h. Stir 204g of roasted soil balls with 78mL of 10% sodium hydroxide solution, and heat up to 75°C for 240min, then add 4.5g of HZSM-5 seed crystals, 484g of water glass and 600g of water, continue stirring for 0.5h, and finally Add 226g of H 2 SO 4 The solution (18wt%) was heated up to 120°C for static crystallization for 6 hours, then heated up to 184°C for static crystallization for 8h, filtered, washed and dried. Figure 1A and Figure 1B It is the SEM image of this embodiment.

Embodiment 2

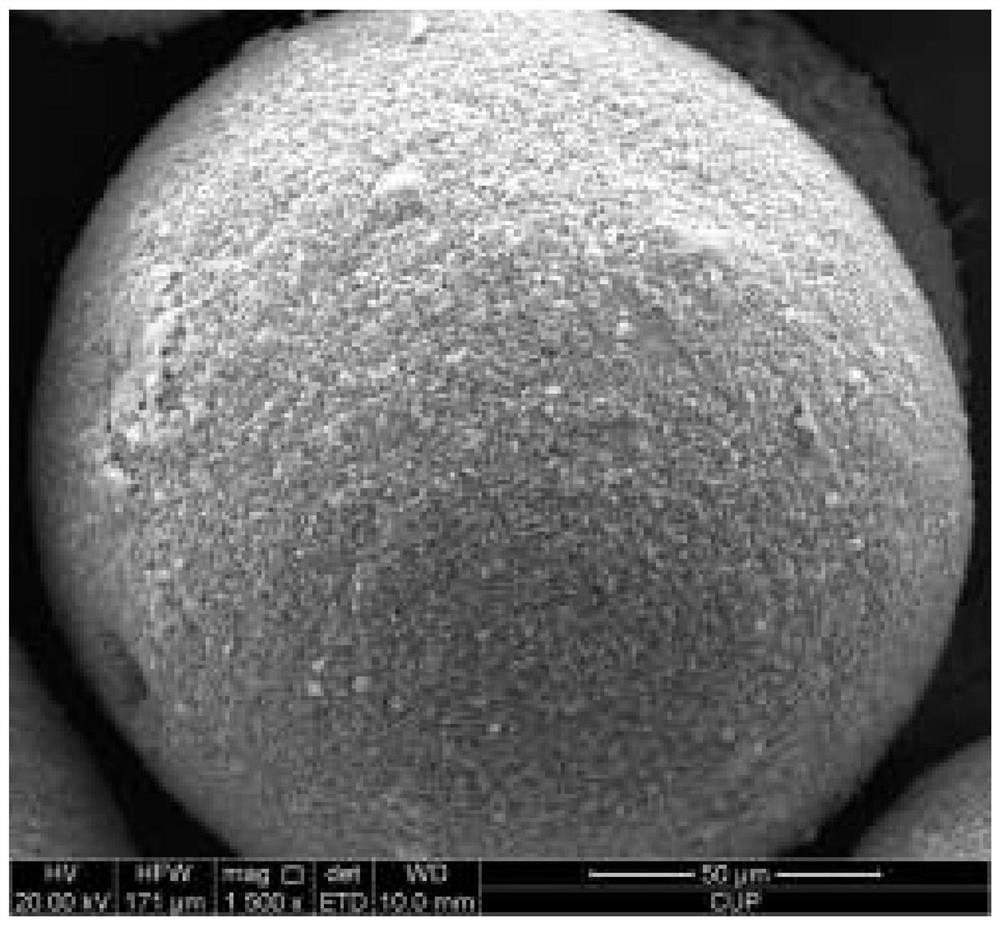

[0044] 10 kg of kaolin and water were prepared into a slurry with a solid content of 28%, and 500 g of aluminum sol was added as a dispersant for spray molding. The obtained spray soil balls were roasted at 980°C for 2h. 178.5 g of roasted soil balls and 300 ml of 14% sodium hydroxide solution were stirred, and the temperature was raised to 85° C. for 100 min, then 12 g of HZSM-5 seed crystals, 124 g of white carbon black and 850 g of water were added, and the stirring was continued for 0.5 h. Raise the temperature to 107°C for dynamic crystallization for 5.5 hours, then raise the temperature to 180°C for static crystallization for 12 hours, filter, wash and dry. Figure 2A and Figure 2B It is the SEM image of this embodiment.

Embodiment 3

[0046] 10 kg of kaolin and water were prepared into a slurry with a solid content of 39%, and 200 g of sodium hydroxide sol was added as a dispersant for spray molding. Roast the obtained spray soil ball at 950°C for 5.5h, stir 255g of the roasted soil ball with 85mL of 17% sodium hydroxide solution, and raise the temperature to 60°C and stir for 280min, then add 2.5g NaZSM-5 seed crystal , 165g water glass and 13g white carbon black, 1567g water, finally add 87g of H 2 SO 4 The solution (8wt%) was heated up to 138°C, stirred intermittently for 5 hours, then heated up to 162°C for static crystallization for 19 hours, filtered, washed and dried.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com