Combined evaporation device and evaporation control method

A technology of evaporation device and control method, which is applied in control/manipulation systems, chemical instruments and methods, special treatment targets, etc., can solve the problems of accumulation of sediment in the evaporator, system blockage, volatile pollutants, etc., and achieve the maintenance of total solids. Balance, ensure continuous and stable operation, and avoid the effect of material accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to more clearly illustrate the above-mentioned purpose, features and advantages of the present invention, specific implementations of the present invention will be described in detail in this part with reference to the accompanying drawings. In addition to the various implementations described in this section, the present invention can also be implemented in other different ways, without departing from the spirit of the present invention, those skilled in the art can make corresponding improvements, deformations and replacements, so the present invention Do not be bound by the specific embodiments disclosed in this section. The protection scope of the present invention should be determined by the claims.

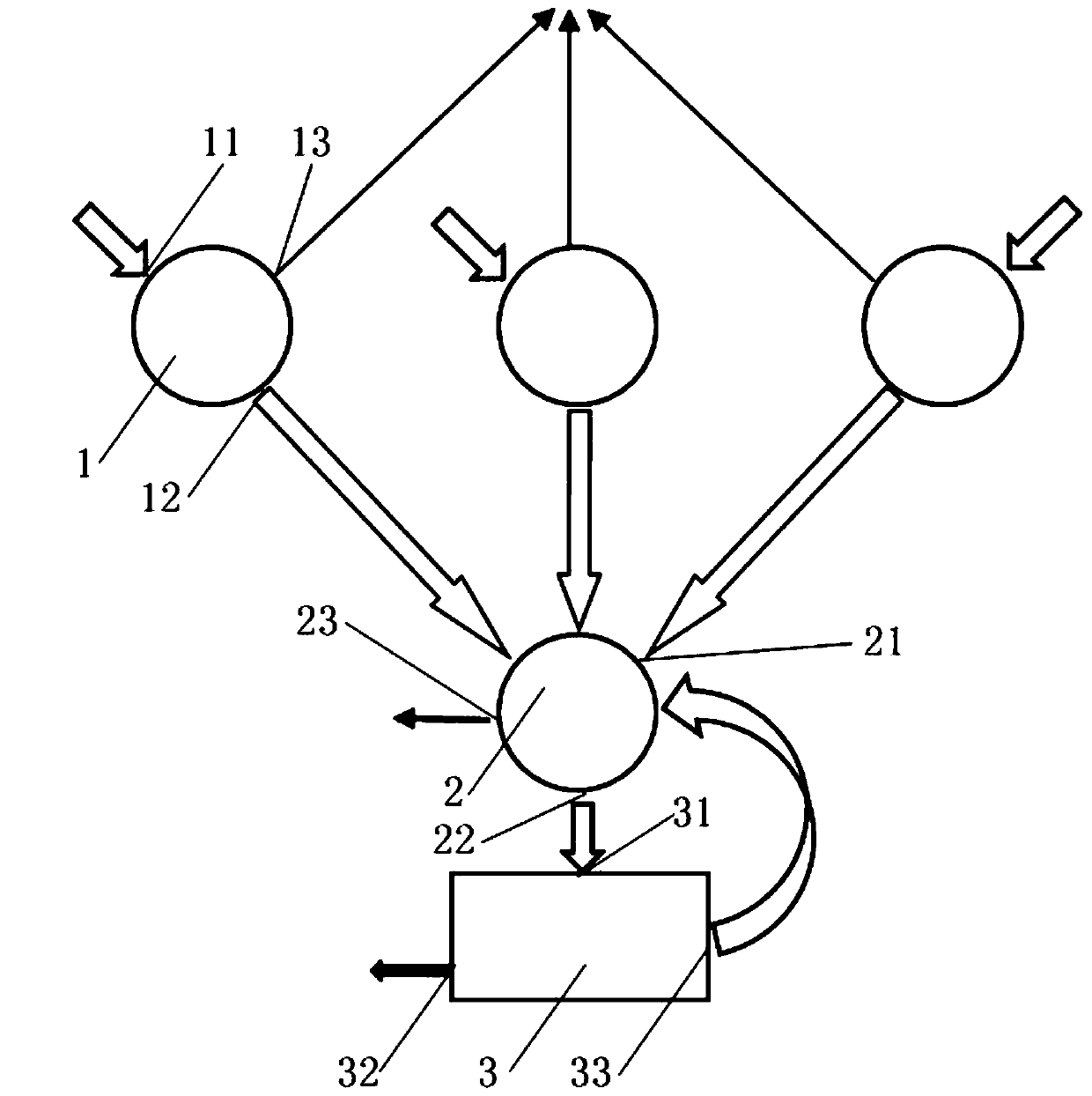

[0044] Such as figure 1 As shown, the present invention proposes a combined evaporation device, which includes a primary evaporator 1 , a final evaporator 2 and a slag-water separator 3 .

[0045] The primary evaporator 1 is provided with a first feed port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com